●

Do not use the power tool near to inflammable materials.

Sparks could ignite

these materials.

●

Do not use diamond cutting discs that require liquid coolants.

The use of

water or other liquid coolants can cause an electric shock.

●

Only allow trained persons to use the power tool.

Apprentices may only use

the power tool when they are over 16, when this is necessary for their training

and when they are supervised by a trained operative.

●

Children and persons who, due to their physical, sensory or mental abilities

or lack of experience and knowledge are unable to operate the power tool

safely may not use this power tool without supervision or instruction by a

responsible person.

Otherwise there is a risk of operating errors and injuries.

●

Only use approved and appropriate marked extension leads with a sufficient

cable cross-section.

Use extension leads up to a length of 10 m with cable

cross-section 1.5 mm

²

, from 10 – 30 m with cable cross-section 2.5 mm

²

.

Recoil and appropriate safety instructions for diamond

slitting and cutting machines

Recoil is the sudden reaction to a sticking or blocked diamond cutting disc. Sticking

or blocking leads to abrupt stopping of the rotating diamond cutting discs. This

accelerates the power tool uncontrollably in the opposite direction to the diamond

cutting discs at the blocking point. If, for example, a diamond cutting disc sticks in

the workpiece or blocks, the edge of the diamond cutting disc immersed in the

workpiece can jam and the diamond cutting disc could break out or cause a recoil.

The diamond cutting discs then move towards or away from the operator depending

on the direction of rotation of the diamond cutting discs at the blocking point. Diamond

cutting discs can also break in the process. Recoil is the result of improper or incor-

rect use of the power tool. It can be prevented by suitable precautions as described

below.

●

Hold the power tool securely and move your body and arms into a position

in which you can intercept the recoil. Always use the additional handle to

have the greatest possible control over recoil forces or reaction torques

when running up.

The operator can control recoil and reaction forces by suitable

precautions.

●

Never move your hand close to the rotating diamond cutting discs.

These

could move over your hand in the case of recoil.

●

Avoid the area in front of and behind the rotating cutting discs.

The recoil

propels the power tool in the opposite direction to the movement of the diamond

cutting discs at the blocking point.

●

Work very carefully in the area of corners, sharp edges etc. Prevent diamond

cutting discs from bouncing off the workpiece and jamming.

The rotating

diamond cutting discs tend to jam at corners, sharp edges and when they bounce

off. This causes loss of control or recoil.

●

Do not use a chain or toothed saw blade.

Such tools frequently cause a recoil

or loss of control of the power tool.

●

Avoid blocking of the diamond cutting discs or too high a pressure. Do not

make excessively deep cuts.

Overloading of the diamond cutting discs increases

the stress on them and their susceptibility to jamming or blocking and therefore

the risk of recoil or breaking of the grinding body or breakage of the diamond

cutting discs.

●

If the diamond cutting discs jam or you interrupt your work, switch the tool

off and hold it steady until the diamond cutting discs come to a standstill.

Never try to pull the still rotating diamond cutting disc out of the cut as this

could cause recoil.

Find and eliminate the cause of the jamming.

●

Do not switch the power tool back on as long as it is in the workpiece. Let

the diamond cutting disc reach full speed before carefully continuing the

slitting or cutting process.

Otherwise the diamond cutting discs might stick,

jump out of the workpiece, cause recoil and/or break.

●

Support boards or large workpieces to reduce the risk of recoil due to

jammed diamond cutting discs.

Large workpieces can sag under their own

weight. The workpiece must be supported on both sides of the diamond cutting

discs both near to the cut and at the edge.

●

Be especially careful with "pocket cuts" in existing walls or other areas

hidden from view.

The entering diamond cutting discs can cause recoil when

cutting into gas or water pipes, electric cables or other objects.

Other safety instructions for diamond slitting and cutting

machines

●

Only use the power tool in connection with a suitable safety vacuum cleaner/

dust extractor.

When working with mineral building materials, e.g. concrete,

steel-reinforced concrete, all types of masonry, all types of screed, natural stone,

a high degree of mineral dust containing quartz is produced which is harmful to

the health. Inhalation of quartz fine dust is harmful to the health. The Directive

89/391/EEC on the taking of measures to improve the safety and health protec-

tion of employees at work obliges the employer to carry out an appropriate risk

assessment at the employees’ place of work, to determine and evaluate the dust

load that can occur and to determine the necessary protective measures. The

German technical ruling for hazardous substances TRGS 559 "Mineral Dust"

defines in Appendix 1 that work with slitting and cutting machines must be clas

-

sified in exposure category 3 if the effectiveness of the extraction has not been

proven. In accordance with EN 60335-2-69 a penetration level of < 0.1 % is

prescribed for sucking health hazardous dusts with an exposure limit/work place

limit (AGW) of > 0.1 mg/m³. When slitting and cutting mineral building materials

at least one safety vacuum cleaner/dust extractor or dust class M should there-

fore usually be used in order to effectively extract the harmful dusts from machines.

Observe the national regulations: You are expressly reminded that, in many

countries, additional regulations regarding the safe use of such vacuum cleaners

for clearing up and disposal of health hazardous dusts are imposed by the national

industrial health and safety authorities, water board and similar authorities.

●

Check the areas concerned for concealed supply lines with a suitable finder

before slitting.

Slitting can damage or sever gas or water pipes, electric cables

or other objects. Damaged gas pipes can cause explosions. Damaged water

pipes and electric cables can damage property or cause electric shocks. If you

do damage a water pipe, make sure that no water gets into the motor.

●

This power tool is not intended for use by persons (including children) with limited

physical, sensory or mental abilities or lack of experience and knowledge unless

they have been instructed in the use of the power tool a person responsible for

their safety and are supervised by such a person. Children must be supervised

to ensure that they do not play with the power tool.

●

Check the power cable of the power tool and extension leads regularly for

damage.

Have these renewed by qualified experts or an authorised ROLLER

customer service workshop in case of damage.

●

Never use the power tool in an explosive environment.

The power tool gener-

ates sparks when in use which could ignite dust and gases.

●

Only use diamond cutting discs with a metal body in accordance with EN

13236.

●

Secure the workpieces to be machined against being flung away.

●

Diamond cutting discs get very hot during work.

Let them cool down before

touching or removing.

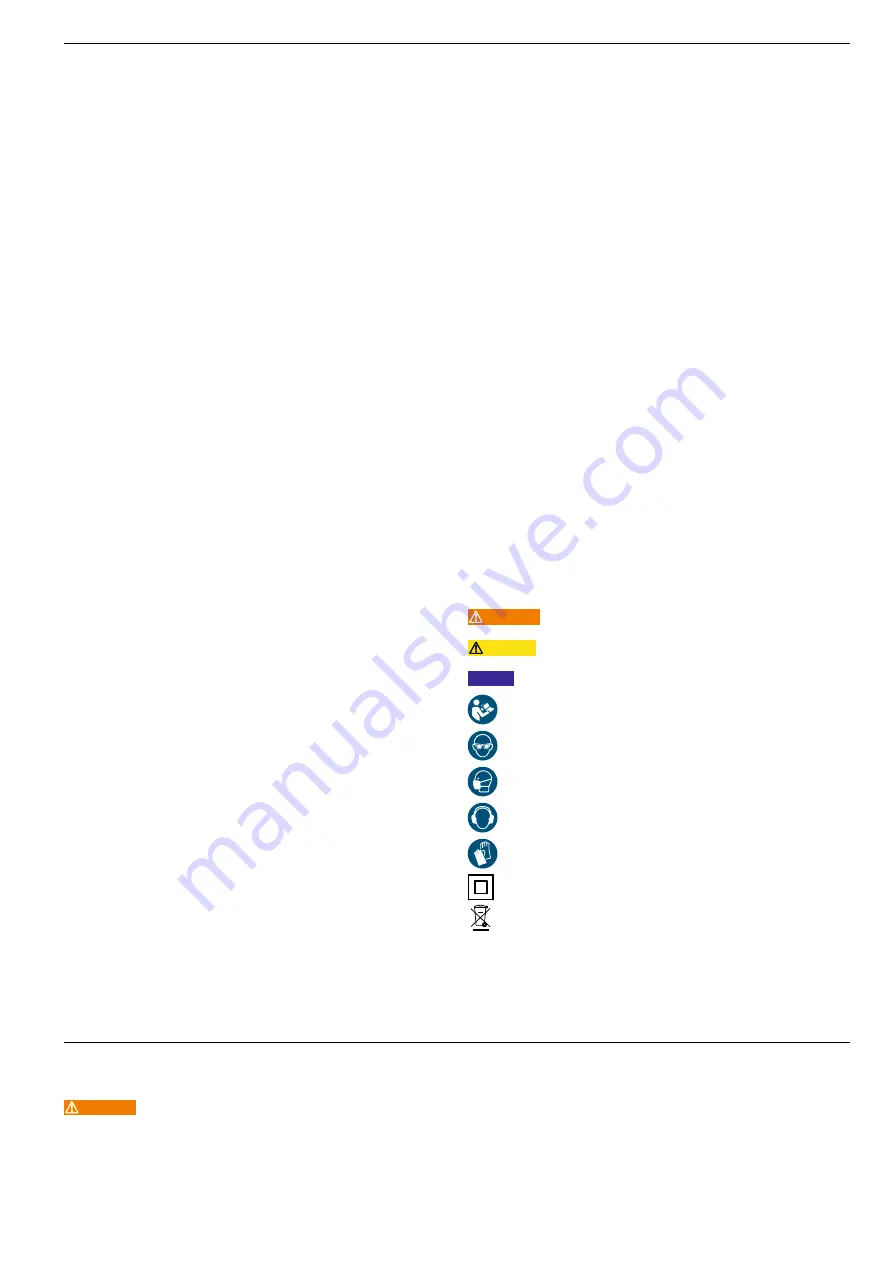

Explanation of symbols

WARNING

Danger with a medium degree of risk which could result in

death or severe injury (irreversible) if not heeded.

CAUTION

Danger with a low degree of risk which could result in minor

injury (reversible) if not heeded.

NOTICE

Material damage, no safety note! No danger of injury.

Read the operating manual before starting

Use eye protection

Use a respirator

Use ear protection

Use hand protection

Electrical device complies with protection class II

Environmental friendly disposal

eng eng

1. Technical data

Use for the intended purpose

WARNING

The ROLLER’S diamond slitting and cutting machines are intended for straight slitting or cutting of mineral building materials such as concrete, steel-reinforced concrete,

all kinds of masonry, all kinds of screed, natural stone without using water in connection with a suitable safety vacuum cleaner/dust extractor using suitable diamond cutting

discs with firm contact with

the contact plate (9). Curved cuts are not permissible because the diamond cutting discs could jam or break. All other uses are not for the

intended purpose and are therefore prohibited.

1.1. Scope of Supply

Electric diamond slitting and cutting machine, Allen key size 13, operating instructions, steel case.