eng eng

CAUTION

CAUTION

The vibration emission value may differ from the specifi ed value during actual

use of the power tool depending on the manner in which the power tool is used.

Dependent upon the actual conditions of use (periodic duty) it may be necessary

to establish safety precautions for the protection of the operator.

2. Start-up

ATTENTION

ATTENTION

If the ROLLER’S Hydro-Polo 22 V has been in storage for a long time, the

overpressure valve must be actuated by pressing the reset key (1) before

putting back into operation. If this is stuck or stiff, no bending may be performed.

The ROLLER’S Hydro-Polo 22 V must then be handed in to a ROLLER author-

ised customer service station for inspection.

2.1. Electrical connection

WARNING

WARNING

Note the mains voltage!

Before connecting the drive unit, the rapid charger or the power supply unit,

check whether the voltage given on the rating plate corresponds to the mains

voltage. On building sites, in a wet environment, indoors and outdoors or under

similar installation conditions, only operate the power tool on the mains with a

fault current protection switch (FI switch) which interrupts the power supply as

soon as the leakage current to earth exceeds 30 mA for 200 ms.

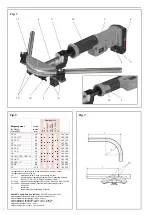

Batteries (Fig. 1)

Total discharging by undervoltage

The Li-Ion batteries may not drop below a minimum voltage because otherwise

the battery (2) could be damaged by “total discharge”, see graduated charging

state display (3). The cells of the ROLLER’S Li-Ion battery are delivered

pre-charged to approx. 40%. Therefore the Li-Ion batteries must be charged

before use and recharged regularly. Failure to observe this regulation of the

cell manufacturer can lead to damage to the Li-Ion battery by total discharging.

Total discharging due to storage

If a relatively low charged Li-Ion battery is stored, self discharging can lead to

total discharge damage of the battery after longer storage. Li-Ion batteries must

therefore be charged before storing and recharged every six months at the

latest and charged again before use.

NOTICE

Charge the battery before use. Recharge Li-Ion batteries regularly to avoid

their total discharge. The rechargeable battery will be damaged by total

discharge.

Use only approved ROLLER’S rapid chargers to charge the ROLLER’S batteries,

see 1.4. Electrical data. New Li-Ion batteries and Li-Ion batteries which have

not been used for a long time only reach full capacity after several charges.

Machine status check for ROLLER’S Hydro-Polo 22 V

ROLLER’S Hydro-Polo 22 V is equipped with an electronic machine status

check with charging state indication (4) by a 2-colour, green/red LED. The

LED lights green when the battery is fully or still suffi ciently charged. The LED

lights red when the battery (2) needs charging. If this condition occurs during

bending and the bend cannot be completed, the bend must be completed with

a charged Li-Ion battery. If the drive unit is not used, the LED goes out after

approx. 2 hours but comes on again when the drive unit is switched back on.

Graduated charging state display of the Li-Ion 21.6 V battery

The graduated charging state display (3) shows the charging state of the battery

with 4 LEDs. At least one LED lights for a few seconds after pressing the key

with the battery symbol (5). The more LEDs that light green, the higher the

charging state of the battery. If a LED fl ashes red, the battery must be charged.

Rapid chargers

The left control lamp lights up and remains green when the mains plug is

plugged in. If a battery is inserted in the rapid charger, the green control lamp

fl ashes to indicate that the battery is charging. The green light stops fl ashing

and remains on to signal that the battery is fully charged. If the red control lamp

fl ashes, the battery is defective. If a red control lamp comes on and stays on,

this indicates that the temperature of the rapid charger and/or the battery is

outside the permissible operating range of the rapid charger of 0 °C to +40 °C.

NOTICE

The rapid chargers are not suitable for outdoor use.

2.2. ROLLER’S Hydro-Polo 22 V (Fig. 1 – 3)

Place the back former support (6) on the bender drive (7) so that the back

formers (8) for the desired pipe size are facing towards the feed piston (9). The

back formers (8) are marked with the pipe size. Fix the back former support

(6) with the wing nut (10). Choose the bending former (11) suitable for the pipe

size. Align the bender drive (7) to the square bar of the feed piston (9) so that

the bending former (11) can be fi tted onto the square bar. The bender drive (7)

can be turned approx. 360°. Then the safety inching switch (12) can be posi-

tioned to the bending former (11) and back former support (6) as required.

3. Operation

3.1. ROLLER’S Hydro-Polo 22 V (Fig. 1 – 3)

ATTENTION

ATTENTION

If the ROLLER’S Hydro-Polo 22 V has been in storage for a long time, the

overpressure valve must be actuated by pressing the reset key (1) before

putting back into operation. If this is stuck or stiff, no bending may be performed.

The ROLLER’S Hydro-Polo 22 V must then be handed in to a ROLLER author-

ised customer service station for inspection.

Functional safety

The bending process in the ROLLER’S Hydro-Polo 22 V is ended by releasing

the safety inching switch (12). If the bending force becomes too great during the

bending process or the feed piston (9) reaches the end stop, an overpressure

valve opens to avoid damage to the ROLLER’S Hydro-Polo 22 V.

Work safety

The drive unit is equipped with a safety inching switch (12) for work safety. This

enables the drive unit to be shut down at any time but especially in the case of

danger. The drive unit can be switched to return in any position.

Work procedure

Turn the back formers (8) so that radius on the back former corresponding to

the pipe size is on the side facing the bending former (11). Insert the pipe

between the bending former (11) and the back former (8). Hold the ROLLER’S

Hydro-Polo 22 V by the switch handle (14) and keep the safety inching switch

(12) pressed until the pipe has reached the desired bending angle. Release

the safety inching switch (12) immediately. Keep the reset key (1) pressed to

move the bending former (11) back to the start position. Remove the pipe.

NOTICE

The bending formers (11) and the back formers (8) of ROLLER’S Hydro-Polo

22 V are made of glass-fi bre-reinforced polyamide. This plastic have very good

22 V

22 V

slide properties, is very strong and heat resistant up to approx. 150°C. Annealed

copper pipes must be cooled down below this temperature.

The aluminium bending formers Ø 15, 18, 22 mm must be used for bending

stainless steel pipes and carbon steel pipes, see fi g..2.

Machine status check

ROLLER’S Hydro-Polo 22 V is equipped with an electronic machine status

check with charging state indication (4) by a 2-colour, green/red LED. The LED

lights green when the battery is fully or still suffi ciently charged. The LED lights

red when the battery needs to be charged. If this condition occurs during bending

and the bend cannot be completed, the bend must be completed with a charged

Li-Ion battery. If the drive unit is not used, the LED goes out after approx. 2

hours but comes on again when the drive unit is switched back on.

Graduated charging state display of the Li-Ion 21.6 V battery

The graduated charging state display (3) shows the charging state of the battery

with 4 LEDs. At least one LED lights for a few seconds after pressing the key

with the battery symbol (5). The more LEDs that light green, the higher the

charging state of the battery. If a LED fl ashes red, the battery must be charged.

Power supply unit (accessory art. no. 571567)

The power supply unit is for operating the power tools on the mains instead of

with the battery. The power supply unit is equipped with overvoltage and

temperature protection. The operating state is indicated by a LED. A lit LED

indicates that the device is ready for operation. If the LED goes out or fl ashes,

this indicates an overcurrent or impermissible temperature. The drive unit cannot

be used during this time. After a dwell time, the LED lights again and work can

be continued.

NOTICE

The power supply unit is not suitable for outdoor use.

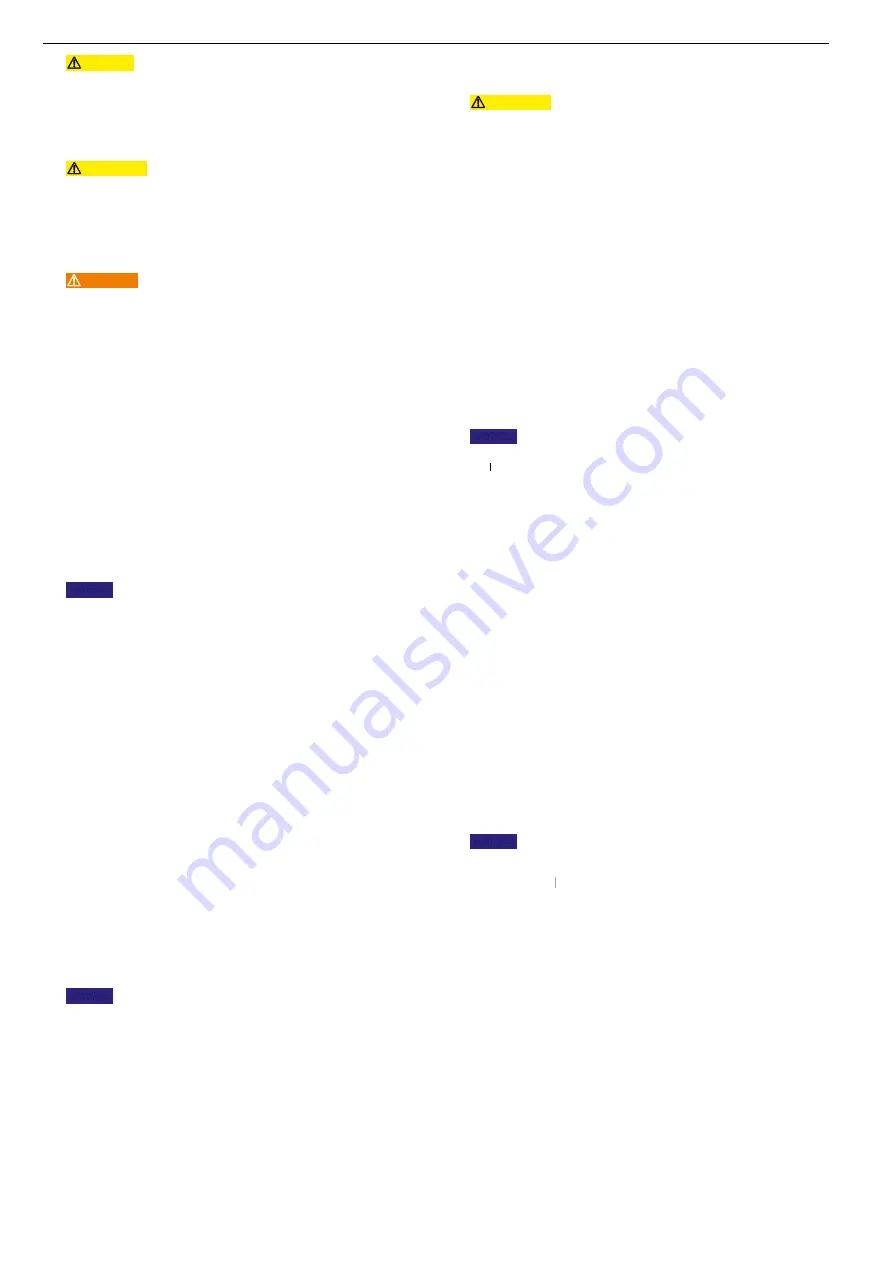

3.2. Bending to size (Fig.

((

3)

There are 2 markings (13) on the outside of the bending formers (11) which

allow exact bending to size. To do this, the dimension mark at which the 90°

bend is to end must be placed against the marking (13) over the centre.

4. Maintenance

Notwithstanding the maintenance work described below, it is recommended

hand in the ROLLER’S Hydro-Polo 22 V together with all tools (e.g. back former

supports, back formers, bending formers) and accessories (e.g. batteries, rapid

chargers, power supply units) to a ROLLER authorised customer service station

at least once a year for inspection and repeated testing of electrical equipment.

In Germany, such periodic testing of electrical devices should be performed in

accordance with DIN VDE 0701-0702 and also prescribed for mobile electrical

equipment according to the accident prevention rules DGUV, regulation 3

"Electrical Systems and Equipment". In addition, the respective national safety

provisions, rules and regulations valid for the application site must be considered

and observed.

10

Summary of Contents for Hydro-Polo 22 V

Page 43: ...43 ...