eng eng

contents of the 1 l bottle of ROLLER’S Plus H-R or ROLLER’S Plus H-K is

suffi cient for a volume of approx. 100 l. ROLLER’S Plus H-R is dyed green in

order to be able to check fi lling and washout, ROLLER’S Plus H-K is dyed blue

to check fi lling. The safety data sheets for ROLLER’S Plus H-R and ROLLER’S

Plus H-K under www.albert-roller.de → Downloads → Safety Data Sheets as

well as other local and national regulations must be observed.

NOTICE

NOTICE

Never allow cleaner or corrosion protection agent to fl ow though the pipes of

ROLLER’S Multi-Control.

Do not use suction/pressure hoses for drinking water lines any more after they

have been used for heating systems.

The built-in nozzles for automatic dosing by ROLLER’S Inject TW and ROLL-

ER’S Inject H are different and are adapted to the properties of the ROLLER

ingredients to be injected. Therefore please always observe the intended use.

2.8. Compressed air pump program (ROLLER’S Multi-Control SL/SLW)

Vessels of all types can be pumped up with this program. Connect the compressed

air hose (23) to the output Pressure test with compressed air, C

air hose (23) to the output Pressure test with compressed ai

air hose (23) to the output Pressure test with compressed ai

ompressed air

pump (Fig. 4 (22)) and connect it to the vessel to be pumped up, e.g. expansion

vessel, tyre. The value 0.02 MPa / 0.2 bar / 3 psi is preset.

2.9. Memory Manager program (data transfer)

The results of the fl ushing and test programs are saved with date, time and log

number in the selected language and can be transferred to a USB stick or

printer (accessory part no. 115604) (neither of which is included in the scope

of supply) for documentation (see 3.8 ).

2.10. Compressed air tools connection

ed

ed

Unlike the described "Compressed Air Pump" program in which the values are

controlled by the electronic control, compressed air tools up to a max. air

requirement of 230 Nl/min can be operated directly from the compressed air

vessel at the compressed air tools connection (Fig. 4 (28)). A compressed air

hose with quick couplings NW 7.2 must be used

hose with quick cou

hose with quick cou

(accessory part no. 115621).

3. Operation

NOTICE

NOTICE

ROLLER’S Multi-Control is not intended/suitable for permanent connection to

the installation. Disconnect all hoses from the installation after completing the

work. ROLLER’S Multi-Control may not be operated unattended.

Before using the ROLLER’S Multi-Control, check whether the respective latest

version software is installed on the input and control unit. For ROLLER’S

Multi-Control S the use of software version as of “03.40, Date 2020-04-08” is

permitted. Select the Settings menu and then Device data to display the version

software. The latest version software (Ver. Software) for the input and control

unit is available by USB stick as a download: www.albert-roller.de → Downloads

→ Software → ROLLER’S Multi-Control → Download. Compare the number

of the version software of the unit with the latest version software number and

of the version software of t

of the version software of t

install the latest version software if necessary.

Download procedure:

1. Download fi le

2. Unpack the ZIP fi le

3. Save "update.bin" on USB stick

4. Plug the USB stick into the USB port of the ROLLER’S Multi-Control

See 2.3 for the further procedure.

NOTICE

NOTICE

The defaults for the different test criteria (test sequences, pressures and times)

in the settings menu of the ROLLER’S Multi-Control SL/SLW are taken from

EN 806-4:2010 or the information leafl et "Leak tests of drinking water installa-

tions with compressed air, inert gas or water" (January 2011) of the German

Central Association for Sanitary, Heating and Air Conditioning (ZVSHK). All

defaults for the test programs can be edited by the user in the Settings menu

and in the Flushing, Test with compressed air, Test with water and Compressed

Air Pump programs. Changes in the Settings menu are saved, i.e. they reappear

the next time the ROLLER’S Multi-Control i SL/SLW

the next time the ROLLER’S Multi-Control i

the next time the ROLLER’S Multi-Control i

s switched on. If the defaults

are only changed in one of the programs, the original defaults appear again

the next time the ROLLER’S Multi-Control

the next time the ROLLER’S Multi-Cont

the next time the ROLLER’S Multi-Cont SL/SLW is switched on. Reset resets

all defaults to factory settings and the language to German (deu) and the date,

time, units formats to DD.MM.YYYY, 24 h, m / bar.

Attention: The user is solely responsible for transferred or newly entered

test criteria (test sequences, pressures and times) or defaults in the

individual programs and the conclusions from the tests. Especially, the

user must decide whether a prescribed stabilisation/wit time is ended

and must confi rm this by \Enter.

The respective national safety provisions, rules and regulations valid for

the application site must be considered and observed.

The electronic memory of ROLLER’S Multi-Control holds 40 fi les (logs). A soon

as a program has been selected from the Start menu and the selected data

have been confi rmed with Enter, a new fi le no. is created automatically even if

the program is then abortede.g. with Esc. If the 40th memory location is occu-

pied, the message "Last fi le no. available". After completing this process, all

fi les should be copied to a USB stick via the USB port (Fig. 2 (33)). The oldest

fi le no. in the memory is then overwritten when further fi les are saved.

Screen display (must be released by Enter):

Screen display (must be released

Screen display (must be released

000425

19.08.2013 10:13

Files 40/40

Last fi le no.

available

Consecutive fi le no. 000425

Date 19.08.2013 Time 10:13 (creation of a new fi le no.)

Files 40/40 (a max. of 40 fi les are saved)

Last fi le no.

available

3.1. Programs fl ush EN 806-4 drinking water installations, program fl ush/desilt

radiators and area heating systems

In EN 806-4:2010 and for Germany additionally in Technical Rules – Worksheet

DVGW W 557 (A) October 2012 of the DVGW German Association of the Gas

and Water Industry e. V. and in the information leafl et "Flushing, disinfection

and commissioning of drinking water installations" (August 2014) of the German

Central Association for Sanitary, Heating and Air Conditioning (ZVSHK) the

fl ushing methods "fl ushing with water" and "Flushing with water/air mixture with

pressure surges" are described. ROLLER’S Multi-Control additionally offers the

fl ushing program "fl ushing with water/air mixture with constant compressed air".

Excerpt from EN 806-4:2010, 6.2.1. "The drinking water installation must be

fl ushed with drinking water after installation and pressure testing as well as

immediately before commissioning." "If a system is not put into operation

immediately after commissioning, it must be fl ushed at regular intervals (up to

7 days)."

3.1.1. Program fl ush EN 806-4 with water (without air supply)

Program fl ush EN 806-4 with water (without air supply)

In accordance with EN 806-4:2010 and for Germany additionally in accordance

with the Technical Rule – Worksheet DVGW W 557 (A) October 2012 of the

DVGW German Gas and Water Association and the information leafl et "Flushing,

disinfection and commissioning of drinking water installations" (August 2014)

of the Central Association for Sanitary, Heating, Air Conditioning (ZVSHK),

Germany, the drinking water used for fl ushing must be fi ltered and must be of

perfect drinking water quality. Filters must hold back particles ≥ 150 µm (Use

ROLLER’S fi ne fi lter with fi lter cartridge 90 µm, Art. No. 115609). The system

must be fl ushed section for section depending on the size of the installation

and the arrangement and lay of the pipes. Flushing must be start on the bottom

fl oor of the building and continue upwards in lines, within a line fl oor by fl oor,

i.e. from the nearest to the furthest line and fl oor. The minimum fl ow velocity

when fl ushing the installation must be 2 m/s and the water in the system must

be replaced at least 20 times during fl ushing.

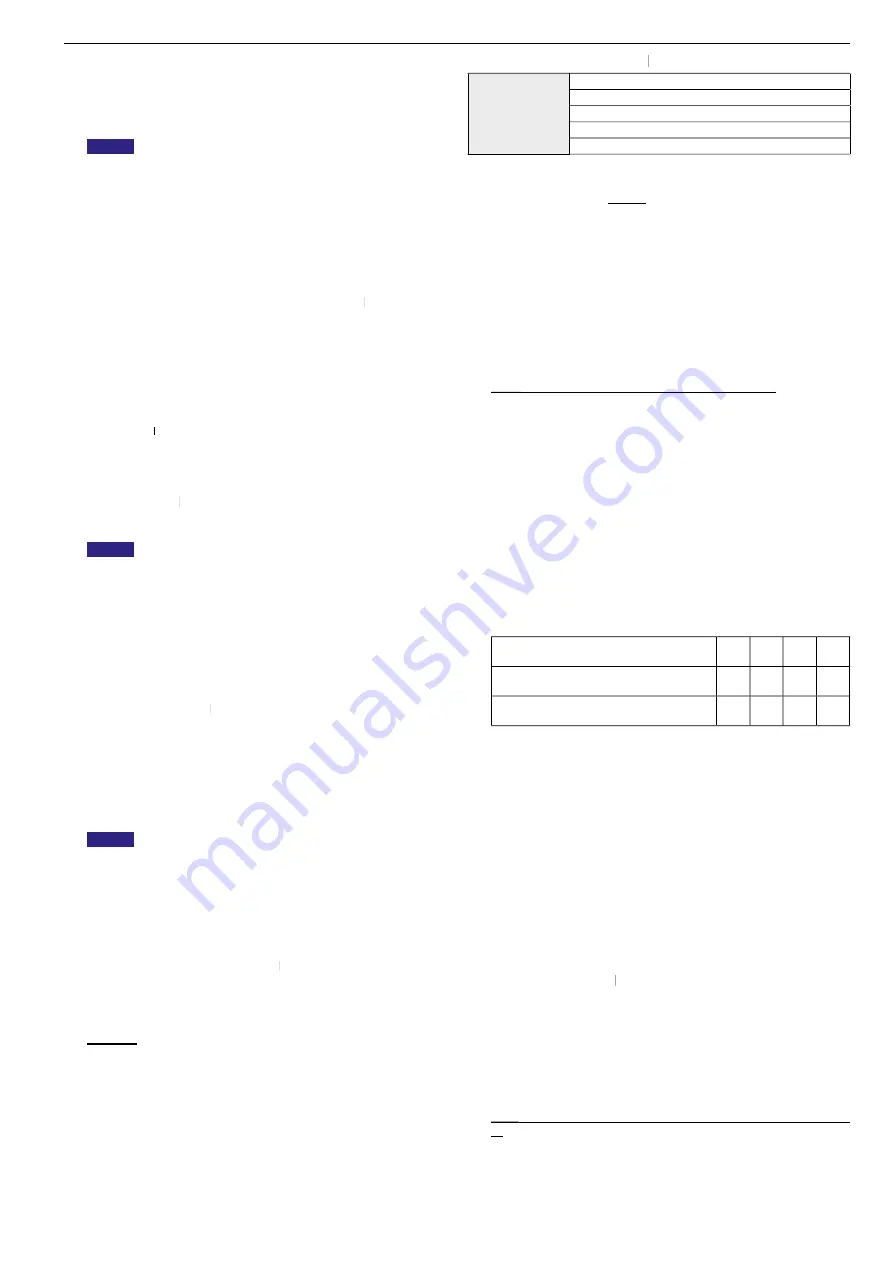

Within the fl oor and single lines, at least as many tapping points as listed in the

following table as a recommended value for a fl ushing section will be fully

opened for at least 5 minutes fl oor by fl oor.

Greatest rated width of the pipe in the

fl ushed section, DN

25

32

40

50

Greatest rated width of the pipe in the fl ushed

section, in inches

1"

1¼" 1½"

2"

Minimum number of tapping points to be

opened DN 15 (½")

2

4

6

8

Table 1: Recommended value for the minimum number of tapping points to be

opened related to the greatest rated width of the distribution line" (single tapping

rate at least 10l/20 s) (Information leafl et "Flushing, disinfection and commis-

sioning of drinking water installations" (August 2014) of the German Central

Association for Sanitary, Heating and Air Conditioning, lines in italics added,

limiting to DN 50). Two or more ROLLER’S Multi-Control can be connected in

parallel to fl ush greater rated widths.

ROLLER’S Multi-Control displays the achieved fl ow velocity and the achieved

water change on the screen among other things.

Program sequence ↑ ↓ (8):

1. Flush \ Enter

2. Flush EN 806-4 \ Enter

3. without compressed air \ Enter

4. Check default max. DN according to table 1 and change if necessary

(11) \ ↓

5. Enter water volume of the fl ushing section VA H

2

O (0-999 l) \ Enter (see

Fig. 6)

6. Open the water supply. Th

6. Open the water suppl

6. Open the water suppl

e values fl ash as long as the minimum fl ow

velocity v H

2

O = 2 m/s and the water change n H

2

O = 20 have not been

reached. On reaching the values \ Enter

(If the defaults v H

2

O and n H

2

O are not reached: \ Esc = cancel, clarify the

cause, repeat the process)

7. Display screen: Water pressure (p H

2

O), minimum fl ow velocity (v H

2

O),

fl ushing time (t H

2

O), water change (n H

2

O), volume of used water (V H

2

O)

\ Enter

8. Esc >> Start menu \ Memory Manager, data transfer >> 3.8

3.1.2. Program fl ush EN 806-4 with water-air mixture with intermittent compressed

Program fl ush EN 806-4 with water-air mixture with intermittent compressed

air

The cleaning effect by fl ushing can be reinforced by adding compressed air. In

accordance with EN 806-4:2010 and information leafl et "Flushing, disinfection

and commissioning of drinking water installations" (August 2014) of the German

Central Association for Sanitary, Heating and Air Conditioning (ZVSHK), the

drinking water used for fl ushing must be fi ltrated whereby particles ≥ 150 µm

drinking wat

drinking wat

must be held back and the water must be perfectly fi t for drinking (ROLLER’S

25