eng eng

1. Technical data

Use for the intended purpose

WARNING

WARNING

Only use the ROLLER’S Solar-Control for the intended purpose of fi lling, fl ushing

and venting solar systems, geothermal systems and fl oor/wall heater systems and

for fi lling tanks. Permissible media: heat transfer liquids, antifreeze, water, aqueous

solutions, emulsions.

All other uses are not for the intended purpose and are prohibited.

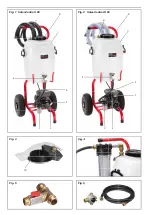

1.1. Scope of Supply

Electrical fi lling and fl ushing unit, 2 fl exible fabric hoses, instruction manual

1.2. Article numbers

ROLLER’S Solar-Control K 60

115302

ROLLER’S Solar-Control I 80

115301

PVC fabric hose ½" T60

115314

EPDM fabric hose ½" T100

115315

EPDM fabric hose ½" T165

115319

30 l plastic tank

115375

Pressure relief valve

115217

Fine fi lter with fi lter cartridge 90 μm

115323

Fine fi lter cartridge 90 μm

043054

Fine fi lter with fi ne fi lter bag 70 μm

115220

Fine fi lter bag 70 μm (10 bags)

115221

Adapter for canister lid

115379

Shut-off valve ¾"

115324

Changeover valve

115325

Changeover valve fl ow direction

115326

Machine cleaner

140119

1.3. Applications

Solar-Control I 80

Solar-Control K 60

Plastic tank volume

30 l

30 l

Transport height

≤ 63 m

≤ 54 m

Volume fl ow

≤ 1.6 m

3

/h

≤ 3 m

33

3

/h

33

Transport capacity at

40 m pumping head

18 l/min

16 l/min

Transport volume

≤ 27 l/min

≤ 36 l/min

Transport pressure

≤ 0.65 MPa/6.5 bar

≤ 0.55 MPa/5.5 bar

94 psi

80 psi

Temperature of the transpor-

ted media (constant load)

≤ 80°C

≤ 60°C

pH value of the

transported media

6.5 – 9.5

6.5 – 9.5

1.4. Electrical data

230 V~; 50 Hz;

230 V~; 50 Hz;

1000 W

860 W

110 V~; 50 Hz;

860 W

Protection class

I

I

Type of protection

IP 55

IP 44

Operating mode

S3 50% (AB

Operating mode

S3 50% (

Operating mode

S3 50% ( 5/10 min) Continuous

AB

AB

operation

1.5. Dimensions

L × W × H

550 × 480 × 970 mm 550 × 480 × 970 mm

(21.7" × 18.9" × 38.3") (21.7" × 18.9" × 38.3")

1.6. Weights

with PVC fabric hoses

20.4 kg (45 lb)

19.8 kg (43.7 lb)

with EPDM fabric hoses

20.0 kg (44.2 lb)

19,4 kg (42.9 lb)

1.7. Noise information

Workplace-related

emissions value

L

pA

= 73 dB (A)

L

pA

= 70 dB (A)

K = 3 dB (A)

K = 3 dB (A)

1.8. Suction and pressure hoses

PVC-

EPDM-

EPDM-

fabric fabric fabric

hose T60 hose T100 hose T165

Hose length

3 m

3 m

3 m

Hose

size

½" ½" ½"

Hose connector, both sides

¾"

¾"

¾"

Temperature resistance

≤ 60°C

≤ 100°C

≤ 165°C

1.9. Fine fi lter with fi ne fi lter bag 90 µm (accessory Art. No. 115323)

Rated width

DN 70

Rated volume fl ow at pressure loss

5m3/h at 20 kPa/0,2 bar/2,9 psi

Rated pressure

300 kPa/3 bar/43,5 psi

Operating temperature

≤ 45°C

Operating pressure

≤ 800 kPa/8 bar/116 psi

2. Start-up

NOTICE

NOTICE

ROLLER’S Solar-Control is not intended/suitable for permanent connection to

the installation. Disconnect all hoses from the installation after completing the

work. ROLLER’S Solar-Control may not be operated unattended.

2.1. Electrical connection

WARNING

WARNING

Caution: Mains voltage present! Before connecting the electrical fi lling and

fl ushing unit, check whether the voltage given on the rating plate corresponds

to the mains voltage. Only connect electrical devices of protection class I to a

socket/extension lead with a functioning protective contact. On building sites,

in a wet environment, indoors and outdoors or under similar installation condi-

tions, only operate the electrical device on the mains with a fault current

tions, only operate the electr

tions, only operate the electr

protection switch (RCD) which interrupts the power supply as soon as the

leakage current to earth exceeds 30 mA for 200 ms.

2.2. Connecting the electrical fi lling and fl ushing unit to the solar system

Connect one of the two fabric hoses to the pressure line connection (1). Connect

the 2nd fabric hose to the return line connection (2) of the plastic tank (3).

Connect the respective free end of the pressure or return line to the ball valves

of the solar system and open the ball valves. Close the connecting valve between

the two ball valves of the solar system. Fill the plastic tank (3) with transported

medium and open the ball valve (4). Plug the mains plug of the electrical fi lling

and fl ushing unit into the socket with a protective earth.

CAUTION

CAUTION

Danger of injury due to escaping transported medium. Tighten the hose

screw connections and check for leaks regularly.

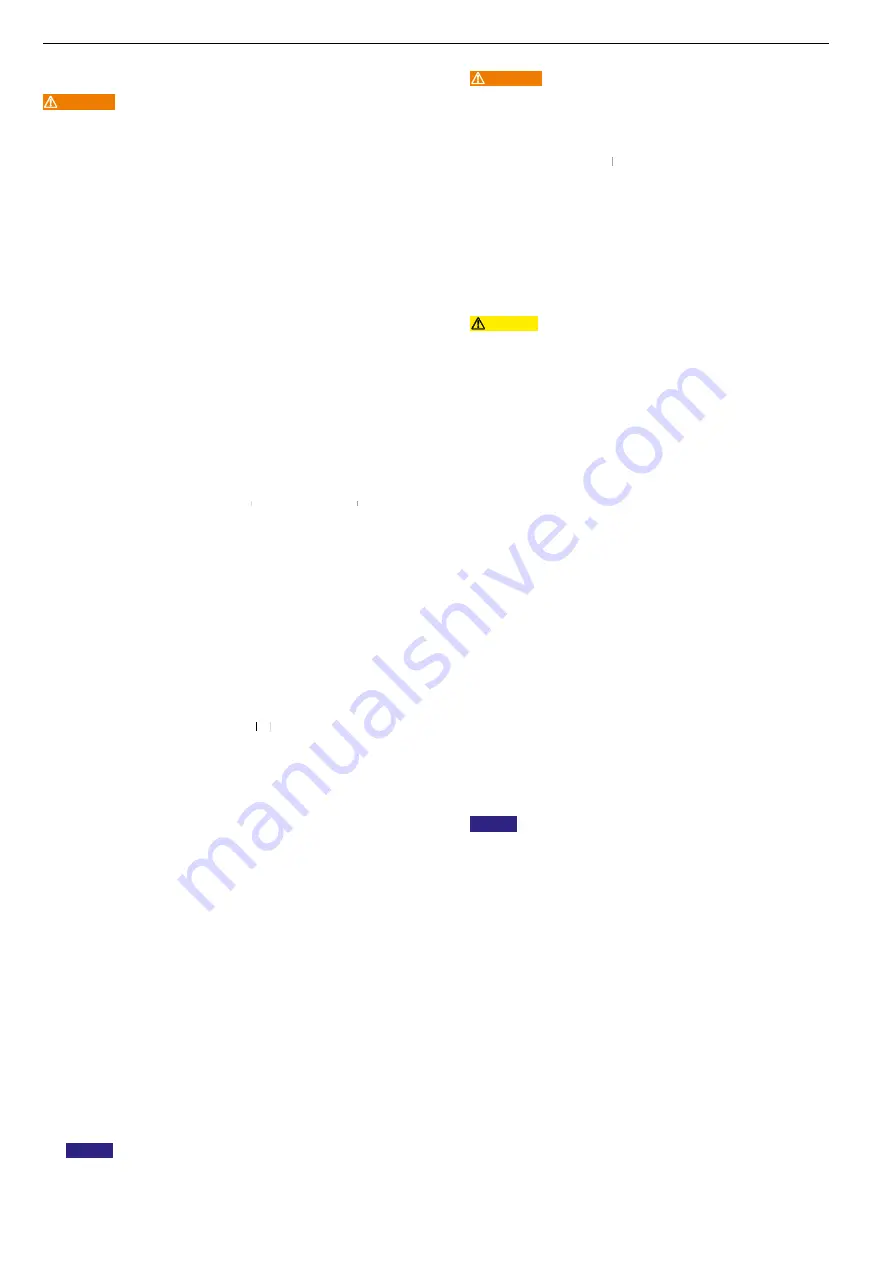

2.3. Screw cover with return line connection ¾" and fi ne fi lter bag 70 μm

(accessory art. no. 115220, Fig. 3)

Remove the screw cover (6). Replace the inner plate of the screw cover (6) by

an adapter (10). Screw the screw cover (6) with adapter to the plastic tank.

Insert the fi ne fi lter into the opening in the adapter, screw the screw cover with

¾" return line connection to the adapter, screw the return line to the return line

connection, close the return pipe (2) connection.

2.4. Fine fi lter unit with large dirt collection vessel (accessory art. no. 115323,

Fig. 4)

Fasten the fi ne fi lter unit to the return line connection (2), connect the return

line to the fi ne fi lter unit.

2.5. Changeover valve for alternative suction of the transport medium from

another tank (accessory art. no. 115325, Fig. 5)

Unscrew the line from the plastic tank (3) to the pump at the ball valve (4) and

screw on the changeover valve for alternative suction of the transport medium

at the ball valve (4). Connect one outlet of the T-piece to the pump line, connect

a line to another tank to the other outlet of the T-piece. Control the fl ow direction

with the valve handle.

2.6. Flow direction changeover valve (accessory art. no. 115326, Fig. 6)

The fl ow direction changeover valve serves for clearing deposits/sludge in solar

stations and underfl oor heating. Screw the fl ow direction changeover valve with

connection (P) to the pressure line connection (1). Connect connection (R) of

the fl ow direction changeover valve and the return line connection (2) with the

enclosed ½" T100 EPDM fabric hose. The two "solar station" connections on

the fl ow direction changeover valve are connected to the outlets on the solar

station with the two ½" fabric hoses belonging to the ROLLER’S Solar-Control.

The pressure line and return line to and from the solar station are switched by

turning the lever on the fl ow direction changeover valve with the pump running.

Deposits/sludge are loosened by the generated pressure pulses.

3. Operation

NOTICE

NOTICE

ROLLER’S Solar-Control is not intended/suitable for permanent connection to

the installation. Disconnect all hoses from the installation after completing the

work. ROLLER’S Solar-Control may not be operated unattended.

Do not switch the Solar-Control K 60 pump on until it is fi lled completely with

liquid. Do not allow the pump to run dry! Procedure for fi lling the Solar-Control

K 60: The plastic tank (3) must be fi lled with liquid. The pressure line (1) and

return line (2) must be connected. Open the ball valve (4). Open the bleed

screw (9). Close the bleed screw (9) as soon as liquid emerges.

The pump of the Solar-Control I 80 also sucks dry.

Switch the pump on at the On / Off switch (5). Open and remove the screw

cover (6) on the plastic tank (3) so that the air can escape from the system.

Observe the liquid level in the plastic tank and, if necessary, refi ll with transported

medium so that no air enters the solar circuit. Flush the solar circuit with the

transported medium. At the inspection glass of the fi ne fi lter (7) or by looking

into the large opening of the plastic tank (6), check whether there are still air

bubbles in the transported medium. Continue the fl ushing process until there

is no more air in the transported medium.

Do not close the pressure and return lines of both pumps for longer than 60 s

because the pumps otherwise run hot and will be damaged.

Switch off the pump (5) after the end of the fi lling and fl ushing process. Close

the ball valves on the solar system, open the conneting valve between the two

ball valves of the solar system. Close the ball valve (4). On the ROLLER’S

Solar-Control I 80, reduce the pressure in the pressure line by opening the

pressure relief valve (8). On the ROLLER’S Solar-Control K60, reduce the

pressure in the pressure line by slightly unscrewing the inspection glass on the

fi ne fi lter (7). The pressure relief valve (8) is available as an accessory for the

ROLLER’S Solar-Control K 60.

8

Summary of Contents for Solar-Control I 80

Page 39: ......