23

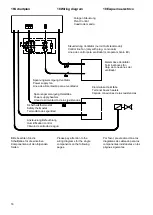

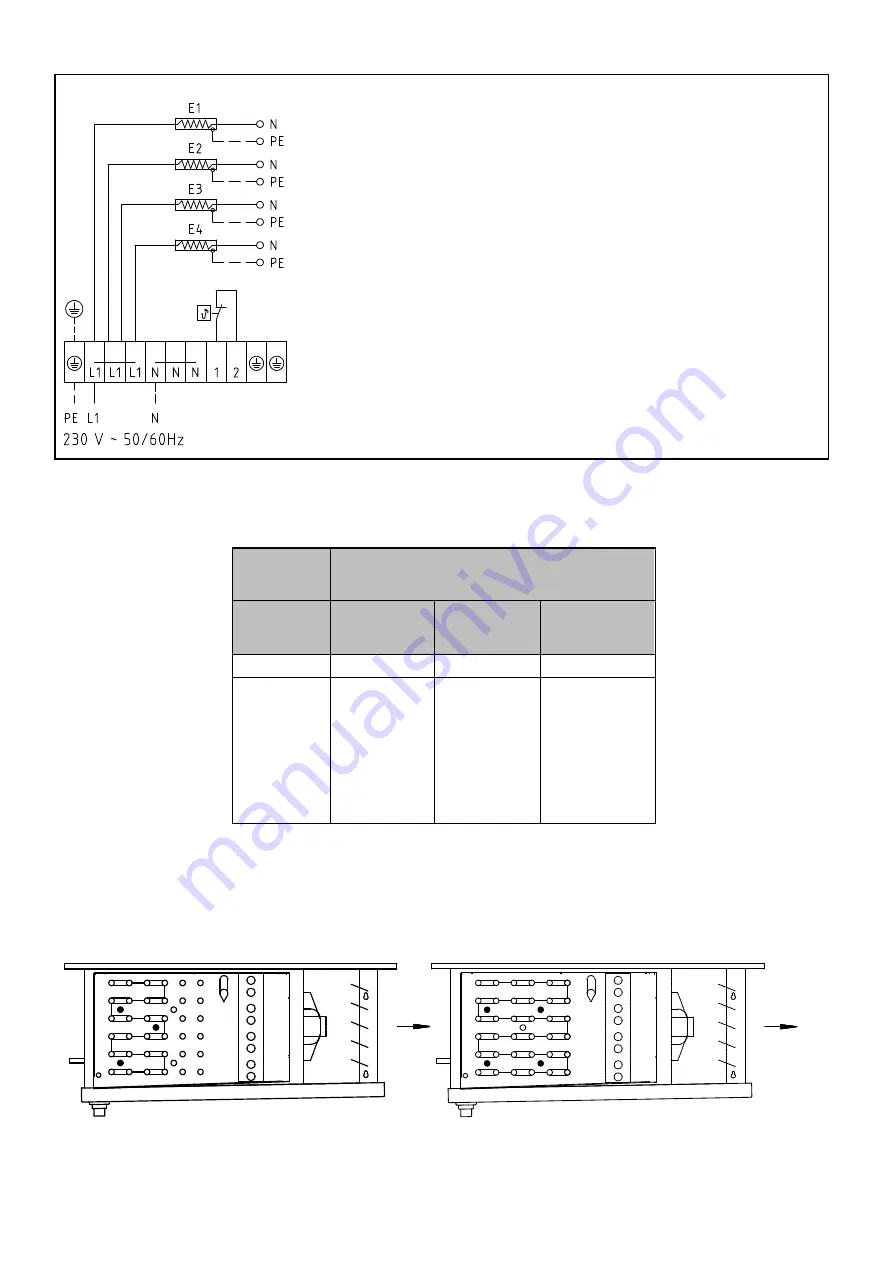

Schaltplan

Wiring diagram

Esquemas de cableado

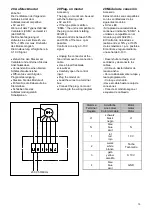

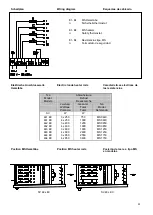

Elektrische Anschlusswerte

Heizstäbe

Electric loads heater rods

Características eléctricas de

las resistencias

Typ

Model

Modelo

Abtauheizung

Defrost

Desescarche

Leistung

Wattage

Potencia

Gesamt

Total

Total

Typ

Model

Referencia

SV

W

W

441 EC

3 x 250

750

MS 0440

461 EC

4 x 250

1000

MS 0440

442 EC

3 x 400

1200

MS 0850

462 EC

4 x 400

1600

MS 0850

443 EC

3 x 600

1800

MS 1250

463 EC

4 x 600

2400

MS 1250

444 EC

3 x 850

2550

MS 1750

464 EC

4 x 850

3400

MS 1750

Position MS Heizstäbe

Position MS heater rods

Posición de las res. tipo MS

en modelos

SV 44x EC

SV 46x EC

1.

E1- E4

MS Heizstäbe

Sicherheitsthermostat

E1- E4

MS heaters

Safety thermostat

E1- E4

Resistencias tipo MS

Termostato de seguridad