Manual No. 4801-6404 Rev 08-12-2013

PolarCool

Page 12 of 17

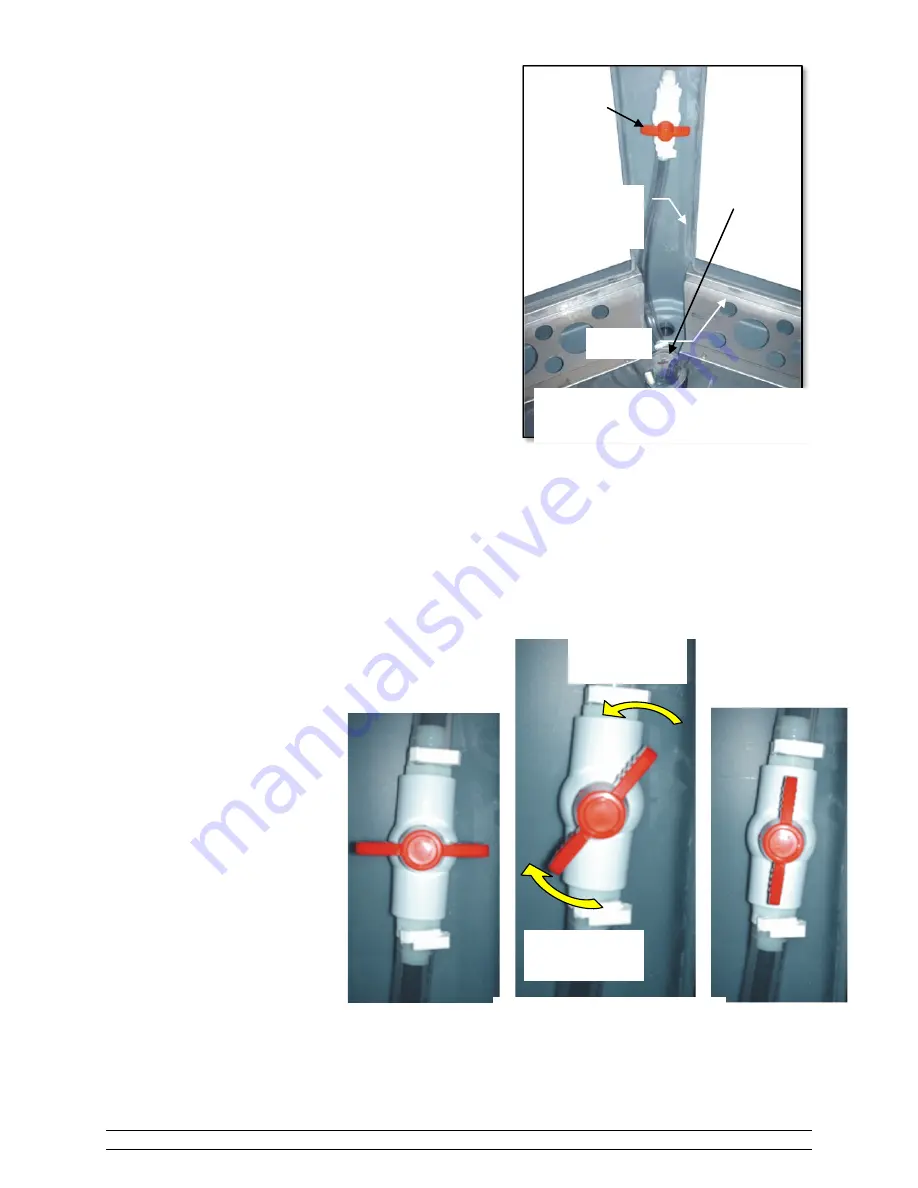

7.9 Flow Control Adjustment

The Flow Control Valve for the PolarCool Zone is shown to the

right. Flow adjustments are factory preset, however can be

adjusted by the user based upon local water pressure and

evaporative conditions at the site. The amount of water flow

affects the efficiency and operation of the PolarCool Zone.

During operation the flow should be adjusted so that sufficient

water soaks the pads, but only enough to completely soak the

pads.

If there is too much water flow, the pads become over-soaked -

that is, there is more water flow than required for proper

evaporation. Surplus water may be sucked into the fan producing

a water droplet spray directly in front of the PolarCool. In some

cases, if you stand in front of the PolarCool you may feel the

water spray! The efficiency of the Polar cool is reduced in this

case. If this happens, reduce the water flow.

If there is too little flow, there will not be enough water to fully soak the pads. Dry spots in the pads will be

visible. Again, this reduces the efficiency of the PolarCool. If this is the case, increase the flow until the pads

become fully soaked.

Adjust the Water Flow

as described above. The

FULL

OPEN and CLOSED

positions of the Valve are

shown in figures at the right.

Valve

Closed

Valve

Full Open

Increase

Pressure

Adjust Water Flow

Flow Control Adjustment

(Pads not shown)

Flow

Control

Valve

Pump

Flow

Control

Valve

Pump

Decrease

Pressure