18

ENGLISH

FRANÇAIS

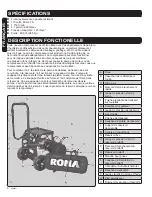

RAK283c

FUNCTIONAL DESCRIPTION

Your new air compressor can be used for operating paint, weed killer, and

insecticide sprayers, air tools, grease & caulking guns, sandblasters, inflation,

etc. A tool with a higher air demand than this compressor can produce may

either not function, or not function well. It may also cause the compressor to run

without stopping for long periods of time, trying to maintain pressure in the tank.

This can cause either the motor or compressor pump to overheat and damage

them. Be sure the requirements of your tools can be met by the compressor.

To compress air, the piston in the pump moves up and down in the cylinder. On

the down stroke, air is drawn in through the inlet valve. Since the discharge valve

remains closed, as the piston goes up, the air in the cylinder is compressed. The

inlet valve closes and compressed air is forced out into the air receiver. A check

valve prevents it from going back into the pump. Working air is not immediately

available. The pump continues to build air pressure until it reaches the required

level on the regulator.

A Wheel

B Oil breather cap

C

Air filter

D Quick-connect air coupler

E Outgoing air pressure gauge

F Folding handle for wheeled

transport

G Regulator

H Tank (system) pressure gauge

I

Tool tray

J Carry handle

K Tank safety valve

L Portable tank bracket

M Rubber strap

N Fixed tank

O Portable tank pressure gauge

P Portable tank connection valve

Q Portable air tank

R Tire chuck

S Fill control valve for portable tank

T Auto-On/Off switch

U Shipping plug

V Oil level sight gauge

W Cushion foot

X Moisture relief petcock