20

ENGLISH

FRANÇAIS

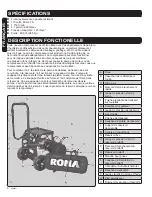

RAK283c

!

3. Remove and discard the oil filler transport plug (

U, fig.3

) on the top of the

crankcase, revealing the oil fill hole.

4. Fill the oil reservoir with SAE-20 heavy duty, non-detergent compressor oil.

In extreme winter conditions, use lighter SAE-10 weight.

5. The resrvoir capacity is approximately 235 ml (8 fl. oz.) There may be some

oil left over from the manufacturing process already in the reservoir. Be

careful not to over-fill.

6. Check the oil level sight glass (V, fig.3). The oil should show level with the

red dot in the centre of the viewing window.

7. Find the oil fill breather cap (B, fig.1 & 4). Ensure there is an O-ring on the

threaded end.

8. Gently screw the oil breather into the oil fill hole. Do not cross-thread or

over-tighten.

BEFORE OPERATING:

1. Check that all nuts and bolts are all snug.

2. Check the quantity and quality of oil (see compressor lubrication, above).

CAUTION:

Before operating this unit, check it throroughly for damage or

corrosion. Ensure that tank, compressor, motor and pump are in good

condition and caps are tight.

INITIAL BREAK-IN

1. Open (turn the brass knurled knob out, counter-clockwise) the air tank

Moisture release petcock (

X, fig.5

) to permit air to escape, so no air pressure

builds up in the air tank.

2. Plug power supply cord into correct power source.

3. Pull up on the Auto-On/Off switch (

T, fig.2

) to start the compressor.

4. Run the compressor in this no-load condition for 1 to 20 minutes to

lubricate the bearings and pistons.

. Close (turn the knurled knob in, clockwise) the air tank Moisture release

petcock.

6. Pressure will build in the tank and the Pressure switch will stop the pump

when it reaches the pressure set on the regulator. Your compressor is now

ready for use.

NOTE:

During the break-in period, there may be a slight smell as the electrical

motor brushes seat themselves. This may last for about 5 minutes and is

normal.

CAUTION!

If the compressor does not run properly after 15 minutes of the

break-in or if you notice any abnormalities, please contact the service

centre.

OPERATING INSTRUCTIONS

!