14

Dimensions (mm)

290*135*280

Electrode Diameter

ø1.6~ ø5.0

Electrode Type

6013, 7018, etc.

Note: The above parameters are subject to change with future machine improvement!

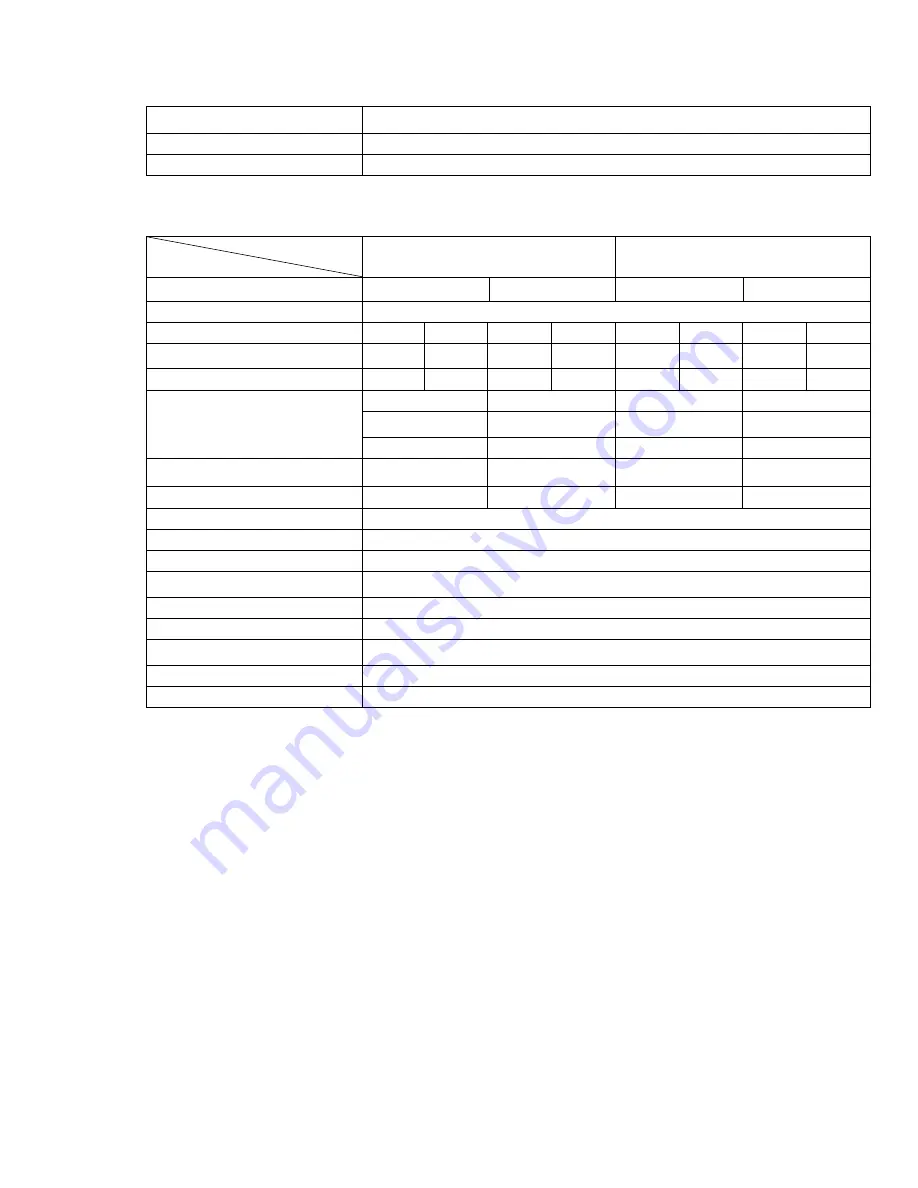

Models

Parameters

RONCHWELD 200 ARC DV

ARC 220 LT DV

Power Supply Voltage (V)

1-110V±10%

1-220V±10%

1-110V±10%

1-220V±10%

Frequency (HZ)

50/60

MMA

TIG

MMA

TIG

MMA

TIG

MMA

TIG

Rated input current (A)

51

33.5

45

31

51

33.5

51

37

Rated input power (KW)

3.8

2.4

6.6

4.5

3.8

2.4

7.2

5.2

Duty cycle (40

℃

10 min)

30% 120A

30% 200A

15% 120A

25% 180A

60% 85A

60% 145A

60% 60A

60% 120A

100% 70A

100% 110A

100% 50A

100% 90A

Welding Current Range (A)

10-120

10-200

10-120

10-220

No Load Voltage (V)

88

24

88

24

Efficiency (%)

≥80%

Power Factor

0.65

Insulation class

H

Protection class

IP23

Cooling

AF

Net Weight (kg)

4.0

Dimensions (mm)

290*135*280

Electrode Diameter

ø1.6~ø5.0

Electrode Type

6013, 7018, etc.

Note: The above parameters are subject to change with future machine improvement!

•

2.3. Brief Introduction

ARC series of welding machines adopt the latest Pulse Width Modulation (PWM)

technology and the Insulated Gate Bipolar Transistor (IGBT) power modules. It uses switching

frequencies in the 20KHz-50KHz ranges so as to replace the traditional line-frequency transformer

type welding machines. Thus, machines are characterized with portability, small size, lightweight,

low energy consumption and noise, etc.

ARC series of welding machines has excellent performance: constant current output makes

welding arc more stable; fast dynamic response speed reduces the impact from the arc length

fluctuation to the current; accurate stepless current adjustment and pre-setting function. There

are also some automatic protection functions for under voltage, over current, over heat, etc.

inside the welder, when the problems listed before occurred, the alarm light on the front panel is