标准化

工艺

批准

日期

设计

制图

校对

审合

处数

标记

更改文件号

重量(g)

共

页

共

日期

签字

上海亿诺科技有限公司

零部件描述

参考编号

材料

公差选择范围

页

外形尺寸

ICT2098

描 述

图 号

序号

备 注

焊枪15/3米/弹性针/蓝色手柄

-------

上海市顾戴路2535弄99号3号楼2楼

16

图 号

序号

1

2

9

3

6

7

8

11

10

12

13

描 述

数量

备 注

1

2

3

4

7

11

1

2

1

3

1

4

1

5

1

6

1

7

ICS0063

ICU0003-08

ICZ6087

ICV0685

IHQ0070

IFT0874

IHJ0715

IHJ0782

14

IHJ0028

IHJ0645

IFT0063

IZT0071

1

1

1

1

3

1

1

1

1

1

1

1

1

8

17

送丝管锁紧螺母

带绝缘层送丝管0.6-0.8 3米 蓝色

IIC0500

导电嘴 0.8/M6*25

喷嘴 D.12 14-15AK

螺丝 M4X6 UNI 6107

15AK 枪颈(包括六角适配器和塑料适配器)

MIG蓝色手柄

焊枪用开关 21.8mm

螺丝 D.3x10

电缆护套 12-16-25 MMQ

电缆支撑用球节 15AK

手柄锁紧环

二氧化碳欧式后把套

数量

1

1

1

9

18

10

9

5

6

8

塑料适配器

六角适配器

IZH0667

IHJ0030

5

4

1

15

ITB0059

欧式中央插头/弹性针

1

ICG6000

19

导电嘴扳手

1

IHJ0063

焊枪锁紧螺母/塑料螺纹

1

ICN0663

同轴电缆组/16mmq/3米

1

3.1

ICZ0087

15AK 枪颈

1

3.1

•

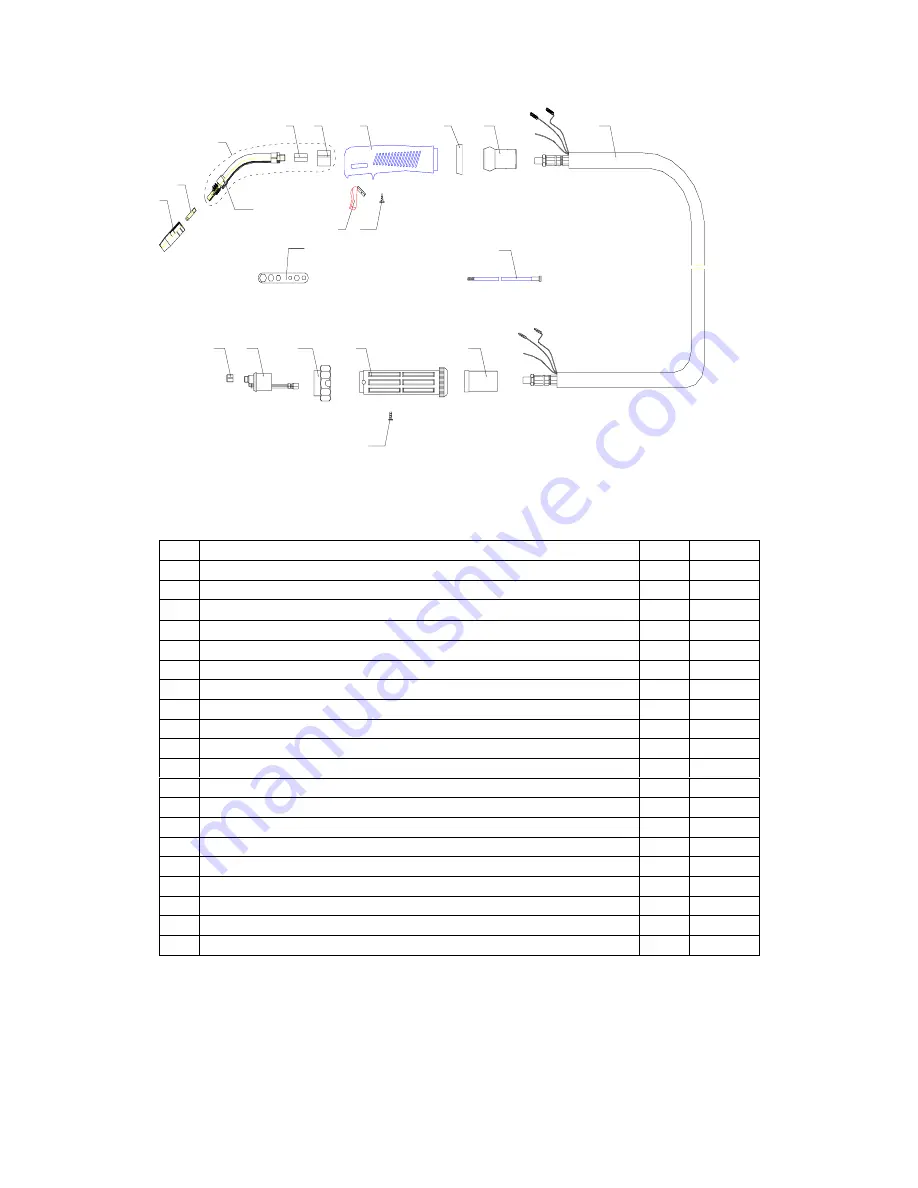

3.4.2. The parts list for the MIG GUN

NO. Description

QTY.

Remark

1

Tip D.12 14-15AK

1

2

Electric nozzle 0.8/M6*25

1

3

15AK Goose gun neck

(

Hexangular adapter and Plastic adapter

)

1

3.1

15AK Goose gun

1

4

Hexangular adapter

1

5

Plastic adapter

1

6

MIG blue handle

1

7

Torch Switch 21.8mm

1

8

Screw D.3*10

3

9

Handle locking ring

1

10

Cable fixing joint 15AK

1

11

Coaxial cable team /16mmq/3m

1

12

Cable thimble 12-16-25 MMQ

1

13

CO

2

Euro-rear thimble

1

14

Screw M4*6 UNI 6107

1

15

Torch locknut /plastic screw thread

1

16

Euro-main socket/flexibility pin

1

17

Feeding pipe locknut

1

18

Insulating feed pipe 0.6-0.8 3m, Blue

1

19

Spanner for the electric nozzle

1

•

3.4.3. The operation for the MIG GUN

1.

Service the wire feed mechanism at least every time the reel is changed.

-

Check the wear of the feed roll groove and change the feed roll when

necessary.

Summary of Contents for Ronch Weld 200MP

Page 1: ...SERIES 200MP 250MP MULTIPROCESS ...

Page 11: ...3 Installation ADJUSTMENT 3 1 Parameters Model Parameters MULTIMIG 200 PFC MV ...

Page 16: ...4 OPERATION 4 1 Layout for the front and rear panel ...

Page 24: ... 5 3 Electrical Schematic drawing ...

Page 25: ...25 200MP 250MP MULTIPROCESS ...