1.

Choose welding mode key: On TIG or MIG, Pressing the key can choose 2T or 4T welding

mode.

2.

Choose welding method key: Pressing the key can choose three function, MMA/TIG/MIG.

3.

Welding current knob: Set the welding current.

4.

Current display: Welding Current display when machine is working, Set current display

before welding. Unit

:

A.

5.

Current LED

:

When the current LED is on, it display the actual output welding current

(MIG).

6.

Wire speed LED

:

You can use current setting knob to set the wire speed when the wire

speed LED is on (MIG).

7.

Voltage display: Welding voltage display when machine is working, Set voltage display

when MIG mode before welding. Unit

:

V.

8.

Welding voltage/Down slope/Arc force knob: On MIG, When the program voltage can’t

perfectly match the welding current, the knob can adjust voltage On TIG, the knob can

adjust the current down time. On MMA, the knob can adjust the force current.

9.

Power Led: Power led is lighted when open the machine.

10.

Alarm Led: When the welder is over voltage, less voltage, over current or over heated, the

alarm pilot lamp will be on.

11.

Wave control knob: Controls arc characteristics, Determines the rate at which the

amperage rises when a short circuit is produced.

12.

Romote Switch

13.

Spool Gun Switch: You can control the spool gun function active (ON) or not (OFF), at the

same time, you must make the Switch 14 in “ON” mode;

14.

Manual wire switch & air check switch: up for manual wire and down for air check.

15.

TIG GAS Connect

16.

MIG GUN Connect.

17.

Polarity conversion: connect to”+”, the MIG gun connecter will be “+”, connect to “-”, the

MIG gun connecter will be “-”;

18.

TIG gun control connecter.

19.

Output cathode

:

When MIG mode, this polarity must connect the work piece

20.

Output anode: When TIG mode, this polarity must connect the work piece

21.

Burnback knob

22.

Slow feed knob

23.

Post flow knob

24.

Pre-flow knob

Summary of Contents for Ronch Weld 200MP

Page 1: ...SERIES 200MP 250MP MULTIPROCESS ...

Page 11: ...3 Installation ADJUSTMENT 3 1 Parameters Model Parameters MULTIMIG 200 PFC MV ...

Page 16: ...4 OPERATION 4 1 Layout for the front and rear panel ...

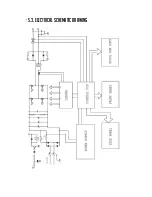

Page 24: ... 5 3 Electrical Schematic drawing ...

Page 25: ...25 200MP 250MP MULTIPROCESS ...