04

No. 5000.331

4210.B

Sous réserve de modifications

Aenderungen vorbehalten

Modifications reserved

Frame

Cage

RONDA

02 Mär 2004

Scale

10 : 1 (5 : 1) (A3H)

+/- 20 µm

mg

Issued

Tolerance

Released

YES

Modified

05 Sep 2016

dh

ÄA 34777

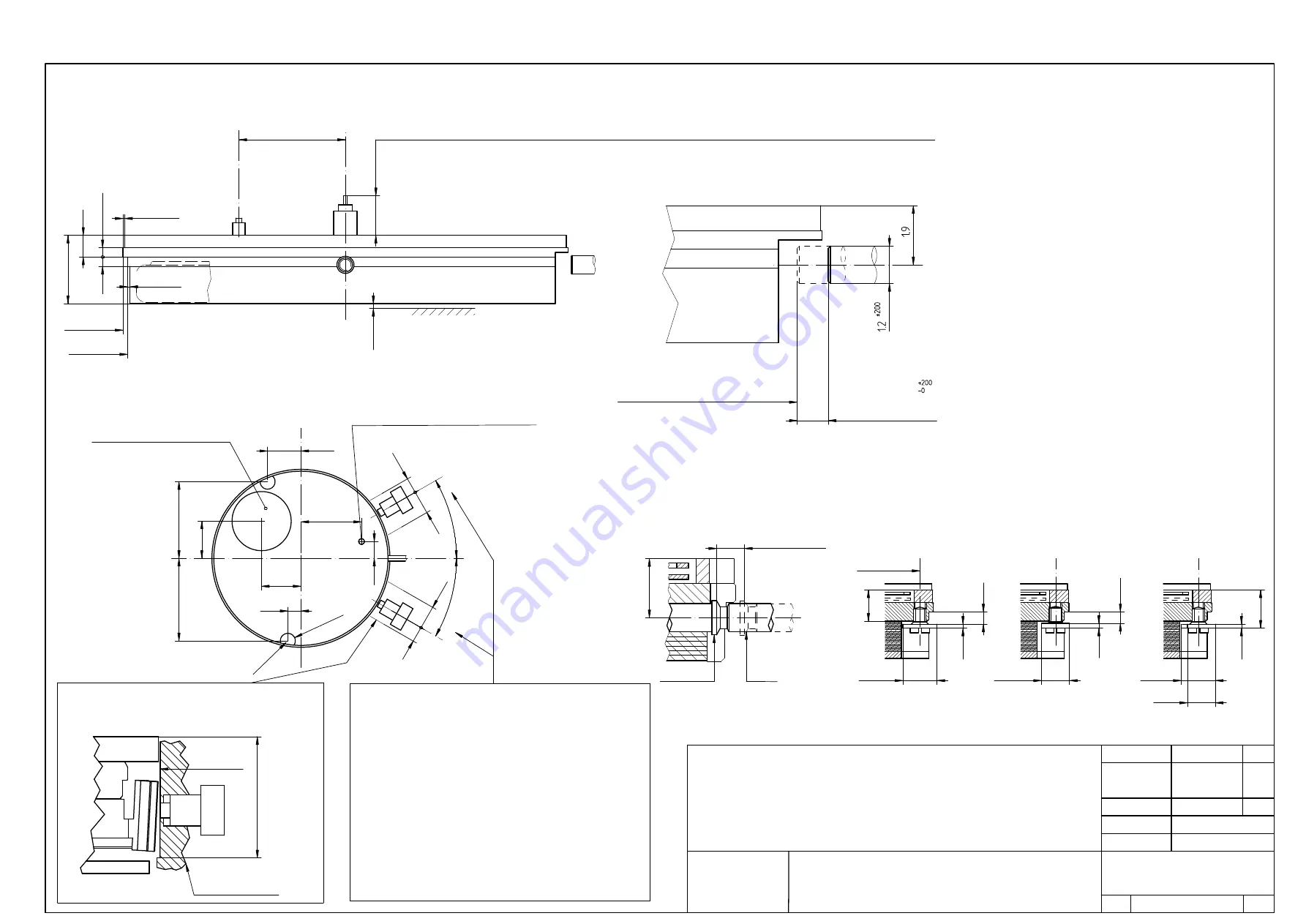

Uhrwerkgestell 12½'''

6.85

Centre<->compteur

Zentrum<->Zähler

Center<->counter

Sécurité

Sicherheit

Security

0

.3

2

.5

5

Aiguillage No.2

Zeigerwerkhöhe Nr.2

Hand height Nr.2

Important: l'aiguillage peut varier selon le modèle

Wichtig: die Zeigerwerkhöhe kann bei verschiedenen Modellen unterschiedlich sein

Important: the hand height can vary between different models

4

.4

+

1

5

0

-

0

1

.4

Ø 28.6

+0

-30

Ø 28

+0

-30

0

.6

±

1

0

0.00-0.15

0

.6

0.00-0.10

Sécurité entre l'aiguille des secondes et le verre:

Sicherheit zwischen Sekundenzeiger und Glas: 0.30mm

Security between second hand and glass:

Le cadran doit être tenu par la boîte

Das Zifferblatt muss durch die Schale gehalten werden

The dial must be hold by the case

La course du poussoir doit être limitée dans le

poussoir lui-même. Sa position poussée doit être

controlée.

Die Weglänge des Drückers ist im Drücker selbst zu

begrenzen. In der gedrückten Stellung ist seine

Position zu kontrollieren

The way of the pusher has to be limited in the

pusher itself. Its position must be checked while

pushed in.

Vis

Schraube Nr. 4000.310

Screw

2

(R 13.43)

0

.2

5

Ø 2.2

0

.8

0

.7

5

0

.3

Vis

Schraube Nr. 4000.195

Screw

Ø 1.8

Ø 2.2

2

.4

5

0

.2

5

Vis

Schraube Nr. 4000.194

Screw

1.8

Stellwelle

Tige

Stem

Filetage:

Gewinde: S 0.90

Thread:

Chemin:

Weg: 0.90

Way:

1

.9

Ø 1.10

course

Weg 1.00

way

Position poussée

Gedrückte Stellung R 13.50 ±50

Pushed in

Poussoirs

Drücker

Pushers

2

.7

Ø 2

.4

S

0.

8

9.75

5

.9

8

6.32

5.35

1

2

.3

2

1

3

.2

6

2.1

Côté fond de boîte

Seite Gehäuseboden

Case back side

B 30°

±1

A 30°

±1

2.5

1.2

5

2.

5

1.

25

Position pour extraire la tige

Position zum Entfernen der Stellwelle

Position to remove the stem

Pile

Batterie (395) Ø 9.50 x 2.60mm

Battery

Dégagement cercle d'entourage pour poussoir

Freistellung Gehäusering für Drücker

Opening movement holder for pusher

L'angle indiqué pour la direction du poussoir

et la position doivent être respectés.

Pour un angle de 0° des poussiors A et B,

voir plan 5000.345

Der angegebene Winkel für die Drückerrichtung und

die Position müssen eingehalten werden.

Für einen Drückerwinkel von 0° bei A und B, siehe

Zeichnung 5000.345

The indicated angle of the pusher direction and

the position must be fullfilled. For pusher angles

of 0° (pusher A and B), see drawing 5000.345.

min. ø 28.6

m

in

.

3

.9

cercle d'entourage

Gehäusering

movement holder

Seulement 1 poussoir

est nécessaire

Nur 1 Drücker

wird benötigt

Only 1 pusher

is required

Summary of Contents for 4210.B

Page 5: ......