10/2013

RONDA AG, Lausen, Switzerland, Phone ++41 (0)61 926 50 00, www.ronda.ch, info@ronda.ch

EM 1

Electronic measurements

5130.D

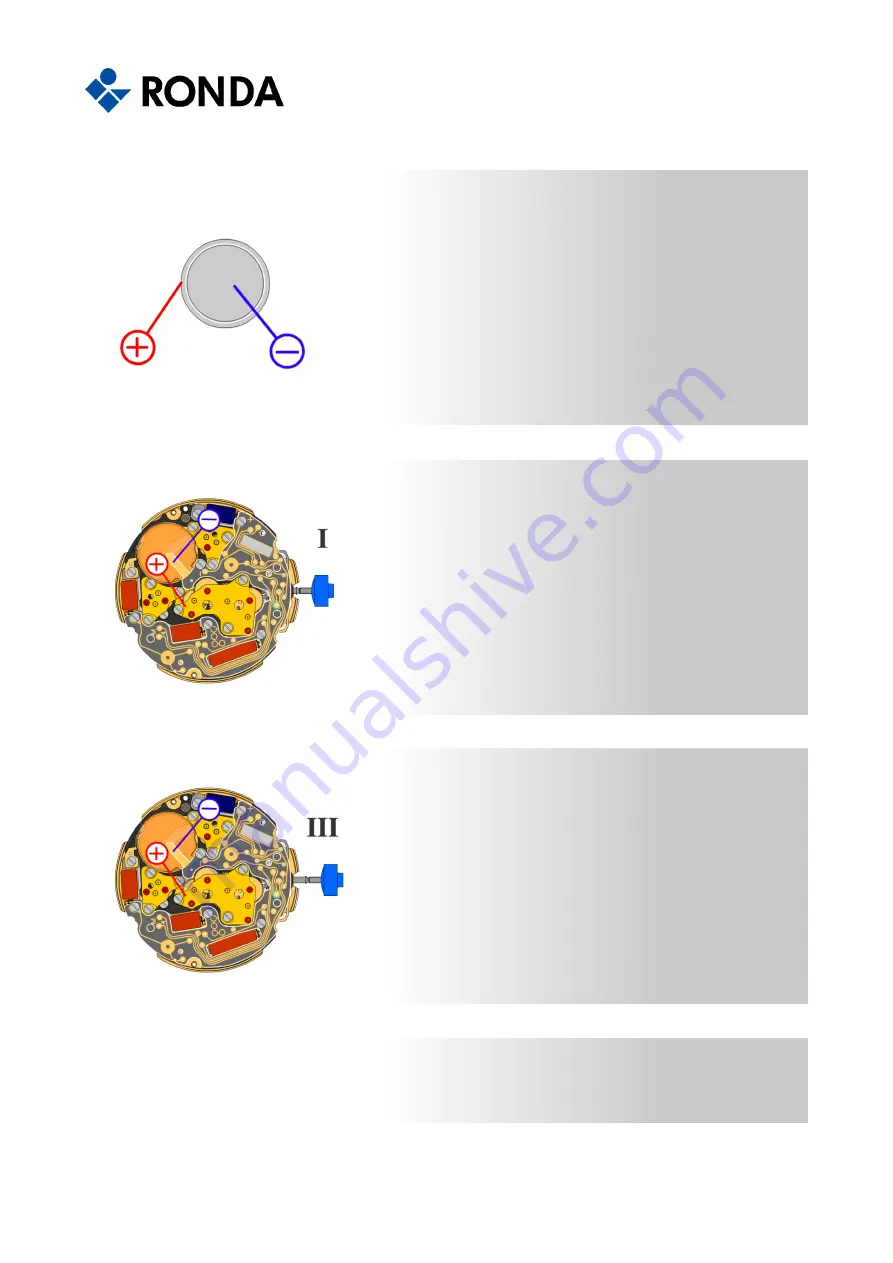

Battery

395

Voltage

1.55 V

Setting stem in position I, calendar not in gear,

60 s measuring interval for rate and consumption:

Typical consumption

Maximal consumption

1.48 µA

1.65 µA

Rate

-10s/M. .. +20s/M.

Lower working voltage limit

1.20 V

Setting stem in position III, 60 s measuring interval:

Typical consumption

Maximal consumption

0.10 µA

0.30 µA

Summary of Contents for 5010.B

Page 5: ......