30

10

20

12

3

6

9

12

2

4

6

8

10

1

11

3

5

7

9

15

60

30

45

2 3

23

I

II

30

10

20

12

3

6

9

12

2

4

6

8

10

1

11

3

5

7

9

15

60

30

45

0 1

1

I

II

30

10

20

12

3

6

9

12

2

4

6

8

10

1

11

3

5

7

9

15

60

30

45

3 1

31

I

II

30

10

20

12

3

6

9

12

2

4

6

8

10

1

11

3

5

7

9

15

60

30

45

1 7

17

I

II

III

30

10

20

12

3

6

9

12

2

4

6

8

10

1

11

3

5

7

9

15

60

30

45

0 3

3

I

II

III

30

10

20

12

3

6

9

12

2

4

6

8

10

1

11

3

5

7

9

15

60

30

45

0 4

4

I

II

III

30

10

20

12

3

6

9

12

2

4

6

8

10

1

11

3

5

7

9

15

60

30

45

0 4

4

I

30

10

20

12

3

6

9

12

2

4

6

8

10

1

11

3

5

7

9

15

60

30

45

3 1

31

I

II

III

30

10

20

12

3

6

9

12

2

4

6

8

10

1

11

3

5

7

9

15

60

30

45

2 3

23

I

II

III

30

10

20

12

3

6

9

12

2

4

6

8

10

1

11

3

5

7

9

15

60

30

45

2 3

23

I

II

III

30

10

20

12

3

6

9

12

2

4

6

8

10

1

11

3

5

7

9

15

60

30

45

2 3

23

III

30

10

20

12

3

6

9

12

2

4

6

8

10

1

11

3

5

7

9

15

60

30

45

2 3

23

65,5% = 40mm Druchmesser

III

A

65,5% = 40mm Druchmesser

III

B

65,5% = 40mm Druchmesser

III

A

65,5% = 40mm Druchmesser

III

I

II

30

10

20

12

3

6

9

12

2

4

6

8

10

1

11

3

5

7

9

15

60

30

45

2 3

23

30

10

20

12

3

6

9

12

2

4

6

8

10

1

11

3

5

7

9

15

60

30

45

2 3

23

30

10

20

12

3

6

9

12

2

4

6

8

10

1

11

3

5

7

9

15

60

30

45

2 3

23

30

10

20

12

3

6

9

12

2

4

6

8

10

1

11

3

5

7

9

15

60

30

45

2 3

23

30

10

20

12

3

6

9

12

2

4

6

8

10

1

11

3

5

7

9

15

60

30

45

2 3

23

30

10

20

12

3

6

9

12

2

4

6

8

10

1

11

3

5

7

9

15

60

30

45

2 3

23

I

30

10

20

12

3

6

9

12

2

4

6

8

10

1

11

3

5

7

9

15

60

30

45

3 1

31

I

II

III

30

10

20

12

3

6

9

12

2

4

6

8

10

1

11

3

5

7

9

15

60

30

45

0 4

4

I

II

III

30

10

20

12

3

6

9

12

2

4

6

8

10

1

11

3

5

7

9

15

60

30

45

0 4

4

I

II

III

30

10

20

12

3

6

9

12

2

4

6

8

10

1

11

3

5

7

9

15

60

30

45

0 4

4

What is the reference time?

The current time is displayed by means of the hour and minute hand.

Parallel to the current time, the reference time runs in the background: the alarm time

refers itself to this reference time. Thus, resetting the time also requires the identical

correction of the reference time.

If the reference time is not synchronised with the current time, this results in the

alarm signal being emitted at a different time to the set alarm time.

Please note:

The reference time must display the same

time as the current time. This means that

resetting the current time also requires the

identical correction of the reference time.

Afterwards, the alarm time has to be reset.

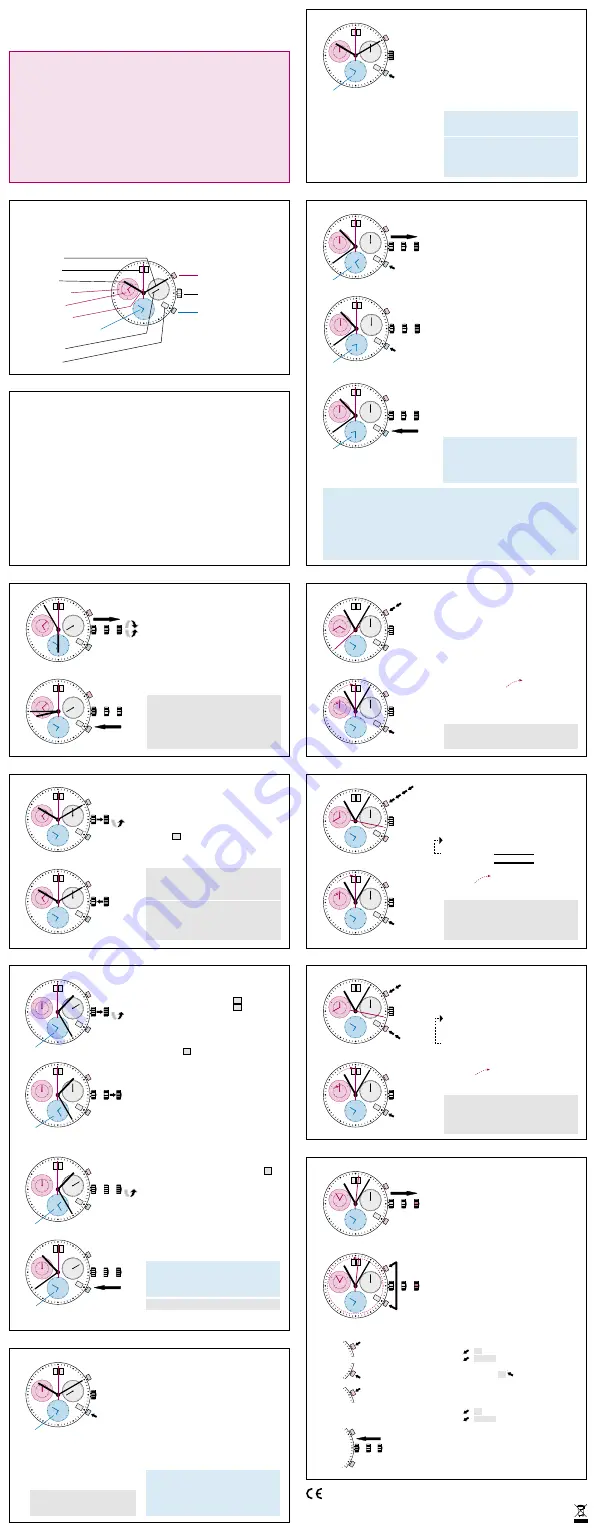

Description of the display and control buttons

Display elements

Minute hand

Date 5130.B

Hour hand

Minute counter

Hour counter

Second counter

Alarm and reference time

(hour and minute)

Second hand

Date 5130.D

Control buttons

Push-button A

Crown

Push-button B

Multifunction movement

The

alarm

and

chronograph

are combined in Cal. 5130.D and 5130.B.

All functions can be operated with the 2 push-buttons and crown.

Initial status (chronograph hands at zero position)

– start the

chronograph

with

push-button A

– switch the

alarm

on and off with

push-button B

Chronograph active

Push-button B is also operative for the chronograph as soon as timing is

started with push-button A.

At the end of timing and when the chronograph hands are reset to the zero

positions the push-button functions once again assume their «initial status».

The alarm cannot be adjusted when the chronograph is active.

Chronograph: Basic function

(Start / Stop / Reset)

Example:

Start: Press push-button A.

Stop:

to stop the timing, press

pushbutton A once more and read

the chronograph counters:

4h / 20 min / 38 sec

Zero positioning:

Press push-button B.

(The chronograph hands will be reset to

their zero positions.)

Please note:

The alarm cannot be used as long as the

chronograph is in operation.

Setting the date (quick mode)

Pull out the crown to position II (the watch

continues to run).

Turn the crown until the correct

date

01

appears.

Push the crown back into position I.

Please note:

The date of the following day must be set

in the calendar changing phase between

approx. 9 PM and midnight.

5130.B: Setting the date too quickly in quick

mode can result in the incorrect date being

displayed. Switching the date between

01 and 31 (position II) restores the syn-

chronisation.

Chronograph:

Accumulated timing

Example:

Start: (start timing)

Stop: (e.g. 15 min 5 sec following

)

Restart: (timing is resumed)

*

Stop:

(e.g.

5 min 12 sec following

)

=

20 min 17 sec

(The accumulated measured time is shown)

Reset:

The chronograph hands are returned to

their zero positions.

Please note:

* Following

, the accumulation of the

timing can be continued by pressing

push-button A

(Restart / Stop, Restart / Stop, …).

Chronograph:

Intermediate or interval timing

Example:

Start: (start timing)

Display interval:

e.g.

20 minutes 17 seconds

(timing

continues in the background)

Making up the measured time:

(the chronograph hands are quickly

advanced to the ongoing measured time).

Stop: (Final time is displayed)

Reset:

The chronograph hands are returned to

their zero position

Please note:

* Following

, further intervals or inter-

mediates can be displayed by pressing

push-button B

(display interval / make up

measured time, ...).

*

Adjusting the chronograph

hands to zero position

Example:

One or several chronograph hands are not

in their correct zero positions and have to be

adjusted (e.g. following a battery change).

Pull out the crown to position III (all

chronograph hands are in their correct

or incorrect zero position.

The display

changes from alarm time to reference

time.

)

Keep push-buttons A and B depressed

simultaneously for at least 2 seconds (the

second counter hand rotates by

360°

corrective mode is activated.)

Adjusting the second counter hand

Single step

65,5% = 40mm Druchmesser

III

A

1 x short

Continuous

65,5% = 40mm Druchmesser

III

A

long

Adjusting the next hand B

65,5% = 40mm Druchmesser

III

Adjusting the minute counter hand

and the hour counter hand

(mechanical coupled)

Single step

65,5% = 40mm Druchmesser

III

A

1 x short

Continuous

65,5% = 40mm Druchmesser

III

A

long

A

Returning the crown to position I

Termination of the chronograph hands

adjustment (can be carried out at any time.

The

display changes from reference to alarm time.

)

Alarm time

Reference time

Reference time

Alarm time

Setting the time and date

Example:

– Date / time on the watch:

17 / 1:25 AM

– Present date / time:

04 / 10:39 PM

Pull out the crown to position II (watch

continues to run).

Turn the crown until yesterday’s date

appears 03 .

Pull out the crown to position III

(the second hand stops.

The display

changes from alarm time to reference

time.

)

Turn the crown until the correct date 04

appears.

* Continue to turn the crown until the

current time 10:39 PM appears.

Push the crown back into position I

(the display changes from reference to

alarm time).

* Please observe the AM / PM clock rhythm.

Please note:

Resetting the time also requires the identical

correction of the reference time.

Please refer to «setting the reference time».

Alarm time

Alarm time

Please note:

The alarm cannot be used as long

as the chronograph is in operation.

Setting the alarm time

Activate the setting mode

Press the push-button B for at least

2 seconds. As soon as the

small minute

hand

jumps forward 1 minute, this mode

is active.

Setting

Short pressing (less than 1 second):

the alarm time is moved forward by the

minute.

Long pressing (longer than 2 seconds):

the alarm time is moved forward until the

push-button is released.

Please note:

If the push-button B is not activated for

10 seconds, the setting mode of the alarm

time deactivates itself. At the same time,

2 beeps are emitted to indicate that the

alarm is switched on.

Switching the alarm on / off

The alarm is switched on / off by briefly

pressing the push-button B:

2 beeps

alarm switched on

1 beep

alarm switched off

Please note:

The alarm can be set maximum 12 hours

before the desired alarm time.

Once the set alarm time has been reached,

a signal is emitted for 20 seconds.

This signal is repeated after two minutes.

Following brief pressing of the push-button B,

the signal is immediately switched off.

Reference time

Reference time

Alarm time

Setting the reference time

Pull out the crown to position III

(second hand stops.

The display changes

from alarm time to reference time.

)

Activating the setting mode

Press the push-button B for at least

2 seconds. As soon as the

small minute

hand

jumps forwards one minute, this

mode is active.

Short pressing (less than 1 second):

the reference time is moved forwards by

the minute.

Medium pressing: (1–2 seconds):

the reference time is moved forwards by

the hour.

Long pressing (longer than 2 seconds):

the reference time is moved forwards until

the push-button is released.

Push the crown back into position I

(the display changes from reference time

to alarm time).

A 1 beep signal indicates that the alarm

is switched off.

09 / 2017

Battery type: 395 / SR927SW

Accuracy: +20 / -10 seconds per month

User’s Manual English

RONDA startech – Movement Cal. 5130.D & 5130.B

You have decided to buy a watch, which was assembled by a watch-

maker using a Ronda movement. Please note that no watches are

produced or distributed under the Ronda Brand.

In case of repairs, guarantee claims and questions concerning

the functioning of a watch, purchasers and consumers should

contact their retailer or the watch manufacturer, for which the

relevant information can be found in the sales or guarantee

documentation provided with the watch.

Setting the time

*

Pull out the crown to position III

(the watch stops).

Turn the crown until you reach the correct

time

8:45.

* Push the crown back into position I.

Please note:

* In order to set the time to the exact second,

must be pulled out when the second

hand is in position «60».

Once the hour and minute hands have been

set,

must be pushed back into position I

at the exact second.

B

B

B

B

A

A

A

A

B

B

A

A

B

A

B

B

A

A

B

B

A

A

B

B

A

A

B

B

A

A

B

B

A

A

B

B

A

A

B

A

B

A

01

07

02

03

09

08

04

06

05

11

10

12

Summary of Contents for 5010.B

Page 5: ......