RONDA normtech

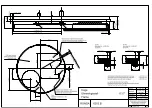

Caliber 6203.B – 11½'''

Functions

– 1 eye

– Multifunction

– Second time zone

– Big date

– 3 hands

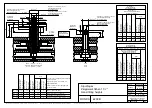

Technical Specifications

Diameter Total

26.00 mm

Case fitting

25.60 mm

Movement height

3.30 mm

Height over standard battery

3.30 mm

Movement rest

0.60 mm

Height over stem

1.80 mm

Length of stem travel

0.90 mm

Force to push the stem for screwed crown

10 / 17,5 N

Stem thread

0.90 mm

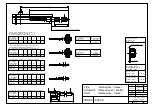

Standard battery

373

Standard battery life

40 months

Battery voltage

1.5 V

Current consumption – typical

1.03 μA (Date

Mechanism not in

Gear)

Current consumption – maximum

1.45 μA (Date

Mechanism not in

Gear)

Useful torque second – typical

6 μNm

Useful torque minute – typical

300 μNm

Operating temperature

0 - 50 °C

Instantaneous rate

-10/ +20 sec/month

Resistance to magnetic fields

18.8 Oe

Resistance against shock

NIHS 91-10

Date: 19.10.2018

www.ronda.ch

Page: 2