3

2) Keep hands and other body parts away from the discharge. For example, do not try to stop leaks with any part of the

body.

3) Always use the nozzle tip guard. Do not spray without nozzle tip guard in place.

4) Only use a nozzle tip specified by the manufacturer.

5) Use caution when cleaning and changing nozzle tips. In the case where the nozzle tip clogs while spraying, follow the

manufacturer’s instructions for turning off the unit and relieving the pressure before removing the nozzle tip to clean.

6) Do not leave the unit energized or under pressure while unattended. When the unit is not in use, turn off the unit and

relieve the pressure in accordance with the manufacturer’s instructions.

7) High-pressure spray is able to inject toxins into the body and cause serious bodily injury. In the event that injection

occurs, seek medical attention immediately.

8) Check hose and parts for signs of damage. Replace and damaged hoses of parts.

9) This system is capable or producing 22.7Mpa. Only use replacement parts or accessories that are specified by the

manufacturer and that are rated a minimum of 22.8Mpa.

10) Always engage the trigger lock when not spraying. Verify the trigger lock is functioning properly.

11) Verify that all connections are secure before operating the unit.

12) Know how to stop the unit and bleed pressure quickly. Be thoroughly familiar with the controls.

d) WARNING-To reduce the risk of injury.

1) Always wear appropriate gloves, eye protection, and a respirator or mask when painting.

2) Do not operate or spray near children. Keep children away from equipment at all times.

3) Don not overreach or stand on an unstable support. Keep effective footing and balance at all times.

4) Stay alert and watch what you are doing.

5) Do not operate the unit when fatigued or under the influence of drugs or alcohol.

6) Do not kink or over-bend the hose.

7) Do not expose the hose to temperatures or to pressures in excess of those specified by the manufacturer.

8) Do not use the hose as a strength member to pull or lift the equipment.

9) The Max. pressure of the air hose is 22.8Mpa, the normal pressure is 22.7Mpa

10) The paint can be compatible: phenol aldehyde paint series, nitryl paint series, alkyd paint series, epoxy resin paint

series, oxidized rubber paint series, latex paint series, water soluble paint series. The paint should be put in shade and

dry place.

11) Be aware of any hazards presented by the material being sprayed and consult the markings on the container or

information supplied by the manufacturer of the material to be sprayed, including requirements for the use of personal

protective equipment.

12) Do not spray any material there the hazard is not know.

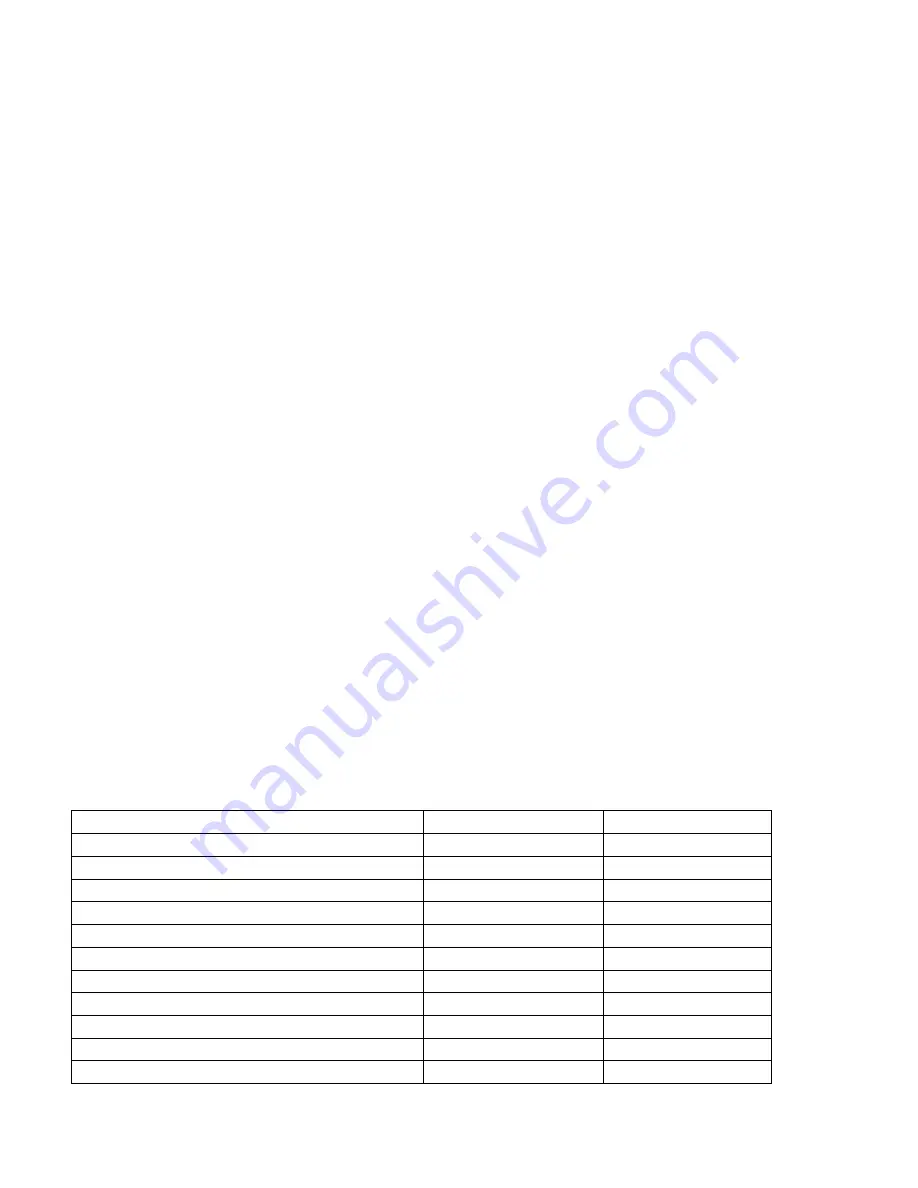

Technical Data

TYPE:

R470

R475

Power requirements

230±10%Vac, 50±1Hz

110±10%Vac, 60±1Hz

Input power

840W

840W

Maximum working pressure

3300PSI

3300PSI

Sound pressure level:

73.9 db

73.9 db

Vibration value:

2.84 m/ss

2.84 m/ss

Maximum delivery gpm (lpm)

2.1

2.1

Working environment temperature requirement:

5

℃

~40

℃

5

℃

~40

℃

Working environment humidity requirement:

30%~95%

30%~95%

Working environment altitude requirement:

1000m

1000m

Transportation and storage temperature requirement:

25

℃

~55

℃

25

℃

~55

℃

Dimensions Weight

14.5kg

14.5kg