- 4 -

WARNING

DO NOT EXCEED Maximum Pressure of Spray Gun or any other parts in the compressor system.

5. After Connect the gun to air supply, please make sure that the fluid cap, container and air hose have been

connected tightly with spray gun.

6. Set up a piece of cardboard or other scrap material to use as a target and adjust for best spray pattern.

WARNING

Never aim or spray at yourself or anybody else which would cause serious injury.

7. Test the consistency of the material by making a few strokes on a cardboard target. If material still appears

too thick, add a small amount of thinner. THIN WITH CARE! Do not exceed paint manufacturer

’s thinning

recommendations.

Operation

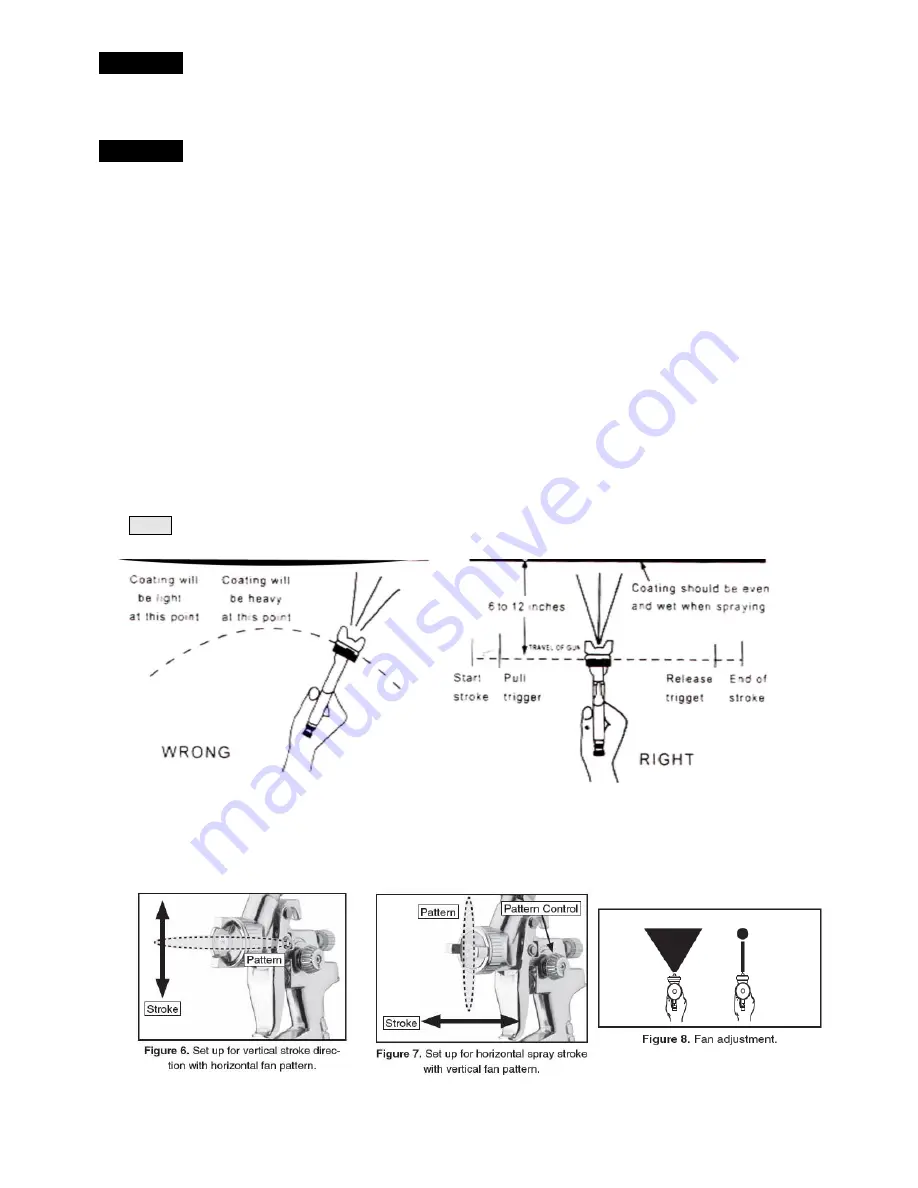

1. Begin spraying. Always keep the gun at right angles to the work .

2. Keep the nozzle about 6 to 12 inches from the work surface. Grip the gun keeping perpendicular with

spraying area then move it parallel for several times, Stopping gun movement in mid-stroke will cause a

build up of paint and result in runs. Do not fan the gun from side to side while painting. This will cause a

build-up of paint in the center of the stroke and an insufficient coating at each end.

3. Trigger the gun properly. Start the gun moving at the beginning of the stroke

BEFORE SQUEEZING THE

TRIGGER

and release the trigger

BEFORE STOPPING GUN MOVEMENT

at the end of the stroke. This

procedure will blend each stroke with the next without showing overlap or unevenness .

4. The amount of paint being applied can be varied by the speed of the stroke, distance from the surface and

adjustment of the fluid control knob.

5. Overlap strokes just enough to obtain an even coat.

NOTE:

Two thin coats of paint will yield better results and have less chance of runs than one heavy layer.

6. Use a piece of cardboard as a shield to catch overspray at the edges of the work to protect other surfaces.

Atomizing Cap and Fan Adjustments

1.The atomizing cap needs to be adjusted for horizontal or vertical spraying patterns. Spraying in the wrong

direction may lead to material build up on the atomizing cap horn. Many performance problems are caused by

clogged atomizing holes on the atomizing cap horns (see Cleaning).

2.Rotating the pattern adjustment control in will give you a range between the two patterns

in Figure 8. .