SERVICE INSTRUCTIONS

• Allen key (3 mm)

• ANDERSEN winch grease

Tools required for service:

• Screwdriver (large)

• Screwdriver (small)

• Winch handle

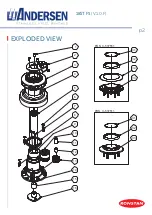

1. Remove screws (1).

2. Remove self-tailing arm (2).

3. Remove drum (4).

4. Pull up the drive shaft (5) gently, using the winch handle.

5. Remove pawls (7) and springs (6).

6. Remove shaft (11) and pull out gearwheel (13).

7. Lift up ratchet gear (10) and pull it out through hole in base (14).

8. Clean all parts in benzine including gear teeth.

9. Assemble in reverse order. During assemble, by the use of a small soft brush lightly grease

all gear teeth, drive shaft, roller bearing, shafts, pawls, springs and bushings. Pawls should

only be lubricated with a very thin film of ANDERSEN WINCH GREASE. It is very important

that pawls can move freely.

IMPORTANT:

When assembling the winch, check the functioning of each pawl by pushing

the pawl against the spring. The pawls should move smoothly and automatically return to

their normal position, where the pawls engage with the teeth. If the pawls do not function

correctly, clean and lubricate the pawls and gears. Check the function of the pawls again to

make sure that it works correctly. If the pawls do not work correctly replace the springs and

recheck the functioning.

Malfunctioning pawls may lead to unexpected release of the winch force resulting in fatal

injuries to the user and others.

Service Kit No: 18 (part. no. 710018) contains spare parts for these winches.

Maintenance instructions for PVD coated stainless steel surfaces.

PVD-coated surfaces should be rinsed regularly in fresh water to remove any salt residue, dirt

or other contaminants and dried gently with a soft cloth. To remove grease or other marks, a

mild abrasive free cleaning agent such as spray-on glass cleaning solution may be used. No

caustic detergents or other aggressive or abrasive cleaning agents should ever be used, as

they may damage the surface.

p5

18ST FS

(V.1.0.F)