Ronstan International Pty Ltd

19 Park Way, Braeside, Victoria 3195 Australia

Tel: +61 (0)3 8586 2000 Fax: +61 (0)3 8586 2099 Email: office@ronstan.com.au

E.U. Representative: Ronstan Denmark ApS

Jægervænget 36, 7100 Vejle, Denmark

Tel: (45) 76 42 77 77 / Email: office@ronstan.dk

1

ISSUED 22/02/13

SAFETY RAIL SYSTEM S22

Certified to European Standard EN795:2012, Type D: Personal fall protection

equipment

– Anchor Devices.

A reliable anchor device is an essential component of any personal protection system.

This system provides a method of attachment for use in conjunction with personal protection

equipment to protect against falls from a height, such as when working outside of

conventional guardrails for cleaning and maintenance purposes. It shall not be used for

lifting equipment or for any other purpose.

Important Advice

The system is tested and certified to the European Standard EN795;2012 Type

D by Lloyd’s

Register, Copenhagen (Denmark), and is appropriate for single person use only.

This anchor device is designed for the attachment of components of a personal fall protection

system (harnesses, lanyards, fall arresters and other devices) in accordance with EN363,

Personal fall protection equipment

– Personal fall protection systems.

Each harness or device must be secured to a separate attachment point.

If this anchor device is to be used as part of a fall arrest system, the user must be equipped with

a means of limiting the maximum dynamic forces exerted on the user during the arrest of a fall to

a maximum of 6KN.

System Description

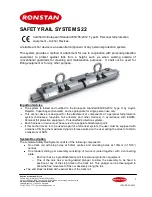

The complete Safety Rail System consists of the following components:

One track rail with stop holes at 50mm centres

and mounting holes at 100mm (3 15/16”)

centres.

One tandem sliding car assembly consisting of two cars joined together with a connecting

plate.

o

Each car has a single attachment point for personal protection equipment.

o

One of the cars has a spring-loaded plunger to allow the assembly to be fixed in

position at any of the stop holes in the track rail. This plunger can be disengaged to

allow the free movement of the car assembly along the rail.

Two end stops installed at the extremities of the track rail.