Operation

Hydraulic system

337 / 564

6.21

Hydraulic system

WARNING

The hydraulic system is under high pressure.

Hot hydraulic fluid may emit from leaks and cause severe injuries! The prestress of the

pressure reservoirs is present even when the remaining hydraulic system is already

pressureless. When dirt, even only in the smallest quantities, enters the hydraulic sys-

tem, this may lead to serious damage to the complete hydraulic system.

– Work on pressure reservoirs of the machine may only be performed by trained per-

sonnel.

– When working on the pressure reservoirs, the machine must first be rendered com-

pletely pressureless.

– The pressure reservoirs themselves may in no case be damaged or opened,

because substantial injuries to people can occur due to the constant prestress.

– During all work on the hydraulic system, ensure extreme cleanliness.

1

2

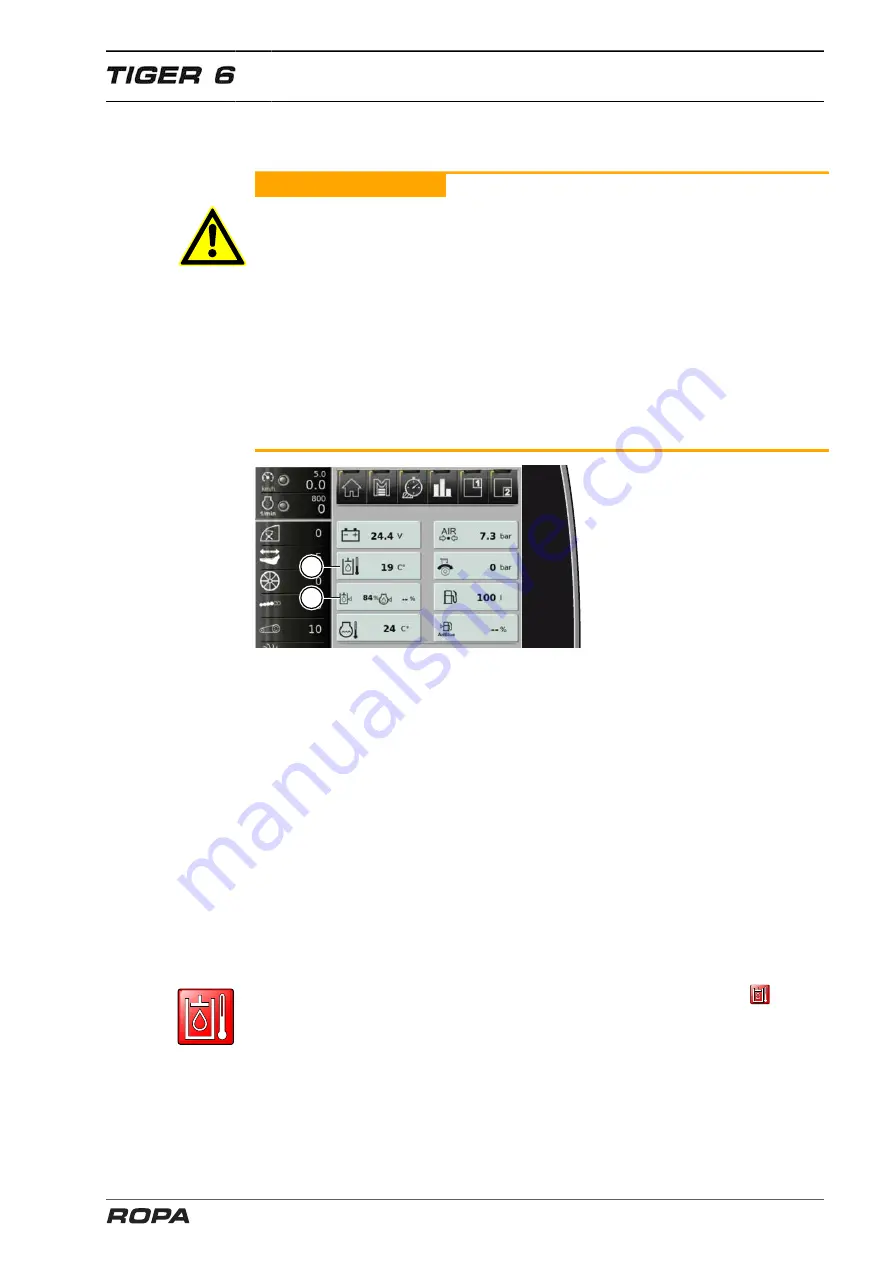

(1)

Hydraulic oil temperature

(2)

Hydraulic oil level

Regularly check the hoses of the hydraulic system for aging and damage! Immediately

exchange damaged or aged hoses. Use only original ROPA hoses or hoses fully con-

forming to the technical specifications of the original hoses! Observe the regionally

applying safety regulations on the service life of hydraulic hoses.

The hydraulic system is operational after the diesel engine has been started. To spare

the hydraulic system, the engine rotational speed during the first minutes (about

5 min.) after a cold start should in no case exceed the value of 1000 rpm. Even higher

rotational speeds for short times should be avoided. As long as the hydraulic fluid has

not reached normal operating temperature (longer times of standstill, low outside tem-

perature), proceed as follows:

Let the engine warm up at 1000 rpm for about five minutes, until the hydraulic fluid has

reached a temperature of about 20° C. The temperature of the hydraulic fluid may be

read at the R-Touch at any time.

If the temperature of the hydraulic fluid is 70° C or higher, or when the icon is dis-

played on the R-Touch, immediately clean the hydraulic oil cooler.

Summary of Contents for Tiger 6

Page 3: ...Contents 3 564 Contents...

Page 4: ...Contents 4 564...

Page 13: ...Preface 13 564 1 Preface...

Page 14: ...Preface 14 564...

Page 22: ...Safety 22 564...

Page 23: ...Safety 23 564 2 Safety...

Page 24: ...Safety 24 564...

Page 41: ...General View and Specifications 41 564 3 General View and Specifications...

Page 42: ...General View and Specifications 42 564...

Page 53: ...General Description 53 564 4 General Description...

Page 54: ...General Description 54 564...

Page 57: ...Operating Components 57 564 5 Operating Components...

Page 58: ...Operating Components 58 564...

Page 98: ...Operation 98 564...

Page 99: ...Operation 99 564 6 Operation...

Page 100: ...Operation 100 564...

Page 226: ...Operation Defoliator 226 564 RIS defoliator RES defoliator...

Page 291: ...Operation Infeed conveyor 291 564 2 1 1 Infeed conveyor control block...

Page 299: ...Operation Strainer wheels turbines 299 564 4 Rpm strainer wheels...

Page 325: ...Operation Bunker unloading 325 564 6 19 Bunker unloading...

Page 361: ...Maintenance and Service 361 564 7 Maintenance and Service...

Page 362: ...Maintenance and Service 362 564...

Page 418: ...Maintenance and Service Defoliator 418 564 Defoliator in the maintenance position...

Page 475: ...Malfunction and Remedies 475 564 8 Malfunction and Remedies...

Page 476: ...Malfunction and Remedies 476 564...

Page 528: ...Lists Tables Plans Diagrams Maintenance Verification 528 564...

Page 558: ...558 564...

Page 559: ...Index 559 564 10 Index...

Page 560: ...Index 560 564...