Maintenance and Service

Hydraulic system

393 / 564

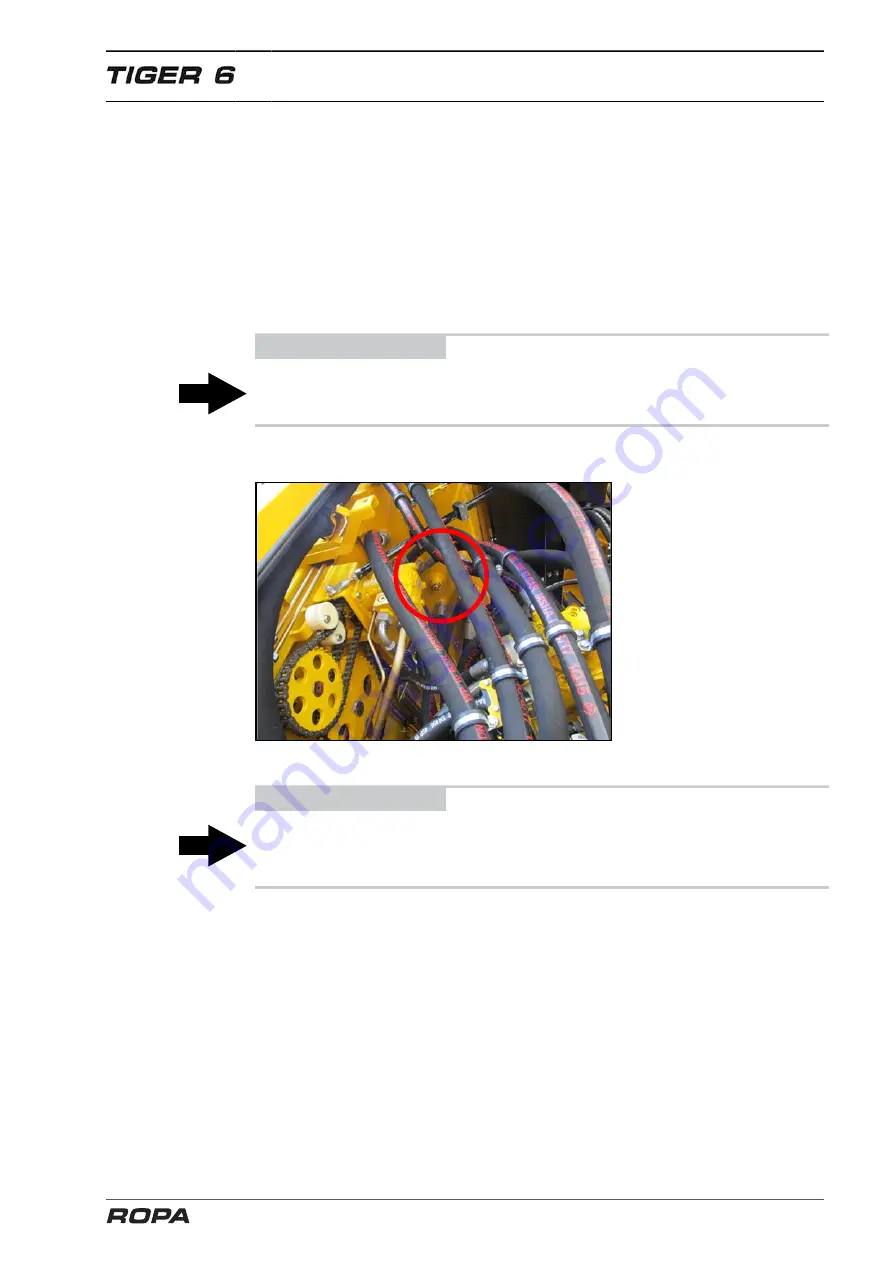

Adding hydraulic fluid:

– Open the protective cover in the rear bunker wall.

– For refilling hydraulic fluid, unscrew the black filling cap (bleeding head) (

2

) from

the lid of the fluid tank.

– When you open the filling lid for the hydraulic fluid, then it is possible that you hear

a 'hissing' sound. This sound is normal.

The filling lid (ROPA item no. 270070000) (

2

) is both a filler and vent filter. It main-

tains the required air balance as the oil level varies (e.g. due to the oil tempera-

ture).

Replace it as soon as it is dirty, but no later than every 2 years.

ADVICE

When using a vacuum pump, do not set a vacuum on more than 0.2 bar.

7.3.1.1

Hydraulic fluid change

Drain valve hydraulic fluid

ADVICE

The entire machine contains more than twice as much hydraulic fluid as can be

drained during a hydraulic fluid change. For this reason it is essential to adhere strictly

to the prescribed intervals for changing the hydraulic fluid.

The hydraulic fluid must be changed annually – best shortly before start of the season.

For this purpose, provide a barrel of sufficient size. Use the fluid drain hose provided

to change the hydraulic fluid. Screw the fluid drain hose onto the valve in the bottom of

the hydraulic fluid tank. The valve opens and the old oil drains.

Prescribed oil variants:

Hydraulic oil HVLP 46

(containing zinc)

ISO-VG 46 as per DIN 51524 part 3

Filling volume:

approx. 220 litres

Summary of Contents for Tiger 6

Page 3: ...Contents 3 564 Contents...

Page 4: ...Contents 4 564...

Page 13: ...Preface 13 564 1 Preface...

Page 14: ...Preface 14 564...

Page 22: ...Safety 22 564...

Page 23: ...Safety 23 564 2 Safety...

Page 24: ...Safety 24 564...

Page 41: ...General View and Specifications 41 564 3 General View and Specifications...

Page 42: ...General View and Specifications 42 564...

Page 53: ...General Description 53 564 4 General Description...

Page 54: ...General Description 54 564...

Page 57: ...Operating Components 57 564 5 Operating Components...

Page 58: ...Operating Components 58 564...

Page 98: ...Operation 98 564...

Page 99: ...Operation 99 564 6 Operation...

Page 100: ...Operation 100 564...

Page 226: ...Operation Defoliator 226 564 RIS defoliator RES defoliator...

Page 291: ...Operation Infeed conveyor 291 564 2 1 1 Infeed conveyor control block...

Page 299: ...Operation Strainer wheels turbines 299 564 4 Rpm strainer wheels...

Page 325: ...Operation Bunker unloading 325 564 6 19 Bunker unloading...

Page 361: ...Maintenance and Service 361 564 7 Maintenance and Service...

Page 362: ...Maintenance and Service 362 564...

Page 418: ...Maintenance and Service Defoliator 418 564 Defoliator in the maintenance position...

Page 475: ...Malfunction and Remedies 475 564 8 Malfunction and Remedies...

Page 476: ...Malfunction and Remedies 476 564...

Page 528: ...Lists Tables Plans Diagrams Maintenance Verification 528 564...

Page 558: ...558 564...

Page 559: ...Index 559 564 10 Index...

Page 560: ...Index 560 564...