Maintenance and Service

Defoliator

417 / 564

7.7

Pneumatic system

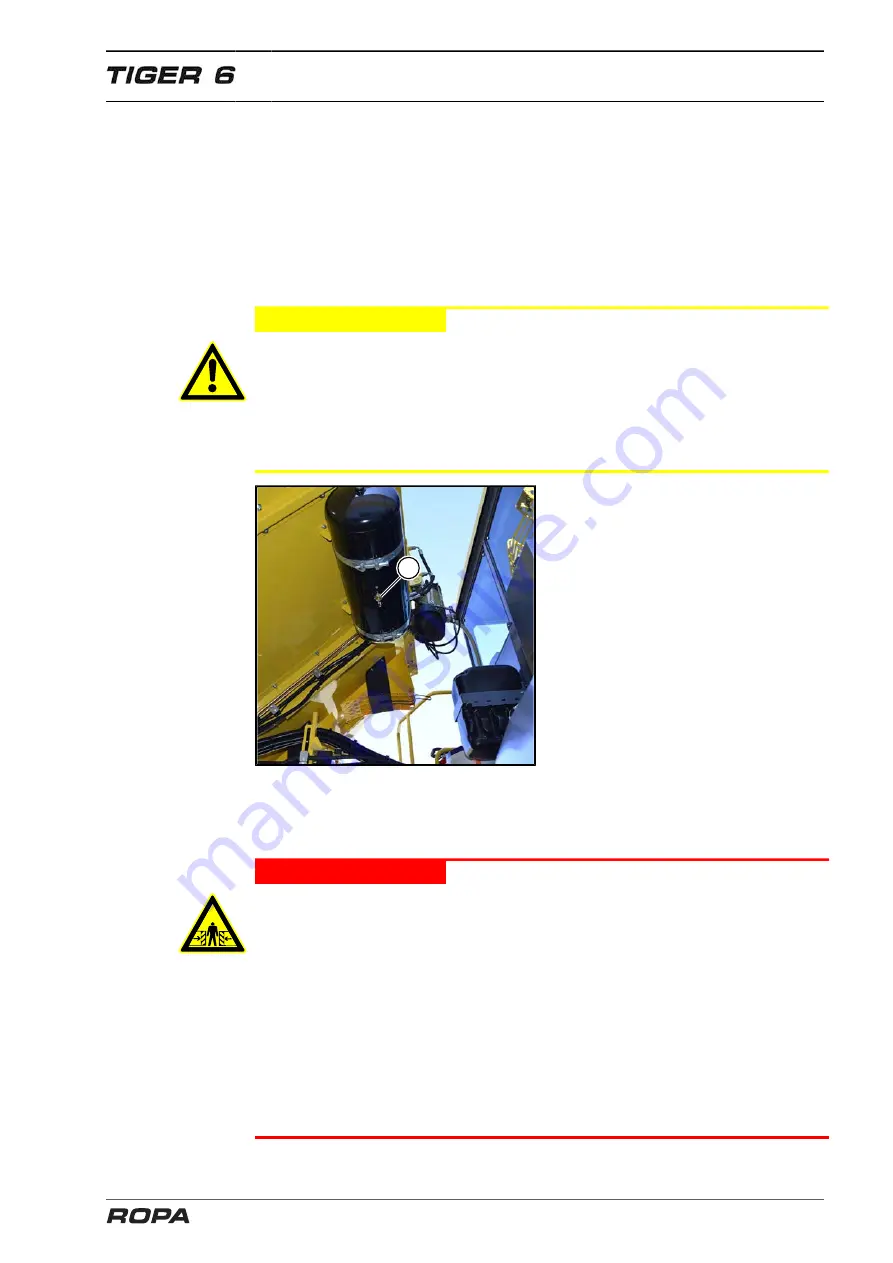

The pneumatic system is to a great extent maintenance-free. Maintenance work is

only required on the compressed air tank. The compressor is maintenance-free. The

compressed air tank is located on the bunker front wall.

Drain the condensation water at the compressed air tank after each

100 operating hours. If the machine is to be taken out of operation for a longer period

(more than a week) the condensation water must also be drained from the com-

pressed air tank. For this, press the drain valve slightly sideward or backward.

CAUTION

Falling and injury hazard!

– Before draining water, stop the machine and switch off the engine.

– The machine must be secured against inadvertent starting of the engine.

– All maintenance and repair work may only be performed by trained personnel.

– Use a stable ladder for all maintenance work on the compressed air reservoir.

– Always wear gloves, protective goggles and suitable protective clothing.

1

(1)

Drain valve

7.8

Defoliator

DANGER

Crushing hazard!

When working on the raised lifting unit, there is the hazard that the lifter or defoliator

suddenly move down. People being in this area may be severely injured.

– Before beginning work, always switch off the engine, switch off the ignition, pull off

the key and lock the driver‘s cabin. The key must be securely kept by a reliable and

trustworthy person during work (kept in possession).

– The defoliator must be moved to maintenance position for work on the bottom of

the defoliator and secured by attaching the two locking links to the side lifter arms.

– Before starting work the lifter must be raised and secured with the two safety

chains attached to the three-point suspension.

– Comply with the applicable regulations for work health and safety when working

under raised loads.

Summary of Contents for Tiger 6

Page 3: ...Contents 3 564 Contents...

Page 4: ...Contents 4 564...

Page 13: ...Preface 13 564 1 Preface...

Page 14: ...Preface 14 564...

Page 22: ...Safety 22 564...

Page 23: ...Safety 23 564 2 Safety...

Page 24: ...Safety 24 564...

Page 41: ...General View and Specifications 41 564 3 General View and Specifications...

Page 42: ...General View and Specifications 42 564...

Page 53: ...General Description 53 564 4 General Description...

Page 54: ...General Description 54 564...

Page 57: ...Operating Components 57 564 5 Operating Components...

Page 58: ...Operating Components 58 564...

Page 98: ...Operation 98 564...

Page 99: ...Operation 99 564 6 Operation...

Page 100: ...Operation 100 564...

Page 226: ...Operation Defoliator 226 564 RIS defoliator RES defoliator...

Page 291: ...Operation Infeed conveyor 291 564 2 1 1 Infeed conveyor control block...

Page 299: ...Operation Strainer wheels turbines 299 564 4 Rpm strainer wheels...

Page 325: ...Operation Bunker unloading 325 564 6 19 Bunker unloading...

Page 361: ...Maintenance and Service 361 564 7 Maintenance and Service...

Page 362: ...Maintenance and Service 362 564...

Page 418: ...Maintenance and Service Defoliator 418 564 Defoliator in the maintenance position...

Page 475: ...Malfunction and Remedies 475 564 8 Malfunction and Remedies...

Page 476: ...Malfunction and Remedies 476 564...

Page 528: ...Lists Tables Plans Diagrams Maintenance Verification 528 564...

Page 558: ...558 564...

Page 559: ...Index 559 564 10 Index...

Page 560: ...Index 560 564...