Lists/Tables/Plans/Diagrams/Maintenance Verification

Maintenance table

531 / 564

9.2

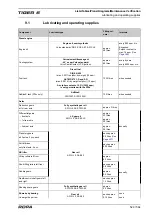

Maintenance table

Maintenance interval

Maintenance work

before har-

vest

start

daily

after the

first 50

oper. hrs.

every 50

oper. hrs.

after the

first 500

oper. hrs.

every 500

oper. hrs.

when

needed

annu-

ally

Diesel engine

Volvo TAD1672VE / TAD1643VE-B

see also Volvo operating manual

Check oil level

X

X

X

X

X

Change engine oil and oil filter

Exception: Sulphur content is max. 15 ppm (

)

Check valve clearance, if needed, adjust

after the first 1000 operating hours, then every 2000 operating hours

Change coolant

every 8000 operating hours, at least every 4 years

Check coolant level, if needed, fill up

X

X

X

X

X

Clean radiator fins

X

Replacing fuel prefilter insert on the elec-

tric pump

Draining water from the water collecting

vessel

X

X

Replace main fuel filter cartridge

every 1000 operating hours, but at least once a year

X

X

every 2000 operating hours, at least every 2 years

X

X

Replace fuel prefilter cartridge

Draining water from the water collecting

vessel

X

X

X

Replace air filter main element

every 1000 operating hours, but at least once a year

X

X

Replace air filter safety filter

Service after 3x main elements

Leak and condition test of all pipes and

hoses

X

X

X

X

Check V-ribbed belt for condition

X

X

X

Exchange V-ribbed belt

every 4 years

AdBlue

®

-Replace filter cartridge (RT6c

only)

every 2000 operating hours, at least every 2 years

Pump distributor gears

Check oil level

X

X

Exchange oil and intake filter

X

X

X

CVR gearbox

Check oil level

X

X

Change oil

X

X

X

Exchange intake and pressure filter

X

X

X

Summary of Contents for Tiger 6

Page 3: ...Contents 3 564 Contents...

Page 4: ...Contents 4 564...

Page 13: ...Preface 13 564 1 Preface...

Page 14: ...Preface 14 564...

Page 22: ...Safety 22 564...

Page 23: ...Safety 23 564 2 Safety...

Page 24: ...Safety 24 564...

Page 41: ...General View and Specifications 41 564 3 General View and Specifications...

Page 42: ...General View and Specifications 42 564...

Page 53: ...General Description 53 564 4 General Description...

Page 54: ...General Description 54 564...

Page 57: ...Operating Components 57 564 5 Operating Components...

Page 58: ...Operating Components 58 564...

Page 98: ...Operation 98 564...

Page 99: ...Operation 99 564 6 Operation...

Page 100: ...Operation 100 564...

Page 226: ...Operation Defoliator 226 564 RIS defoliator RES defoliator...

Page 291: ...Operation Infeed conveyor 291 564 2 1 1 Infeed conveyor control block...

Page 299: ...Operation Strainer wheels turbines 299 564 4 Rpm strainer wheels...

Page 325: ...Operation Bunker unloading 325 564 6 19 Bunker unloading...

Page 361: ...Maintenance and Service 361 564 7 Maintenance and Service...

Page 362: ...Maintenance and Service 362 564...

Page 418: ...Maintenance and Service Defoliator 418 564 Defoliator in the maintenance position...

Page 475: ...Malfunction and Remedies 475 564 8 Malfunction and Remedies...

Page 476: ...Malfunction and Remedies 476 564...

Page 528: ...Lists Tables Plans Diagrams Maintenance Verification 528 564...

Page 558: ...558 564...

Page 559: ...Index 559 564 10 Index...

Page 560: ...Index 560 564...