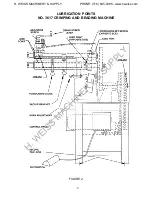

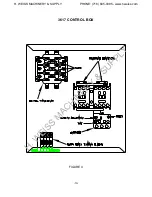

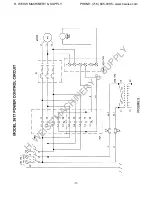

Roper Whitney - Model 3617 Crimping & Beading Machine Manual

3617 CRIMPING & BEADING MACHINE

PARTS LIST

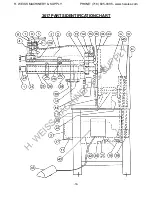

REFER TO PARTS IDENTIFICATION CHART

INDEX

PART #

DESCRIPTION

INDEX

PART #

DESCRIPTION

1

764560158

Roll Nut (2 req’d)

23

764680165

Lower Shaft

2

764680164

Upper Shaft

24

764830168

Thrust Washer

3

764220205

Motor Cover

(front)

4

243700017

Front Box Assy

25

243700019

Horn Assy

5

764140220

Frame

26

259700094

Gauge Assy

6

764650157

Adjusting Screw

28

764160151

Tie Bolt

7

230700011

Crank Screw Lever

29

764180149

Saddle

8

764260162

Spring Cup

30

764650166

Adjusting Screw

9

764160163

Stud

31

764680167

Adjusting Stud

10

664184544

Spring

32

764630155

Pipe Spacer

11

764220222

Motor Cover

33

764220203

Rear Cover

12

764830169

Thrust Washer (rear)

34

764380145

Gear

13

764380154

Connecting Gear (2)

35

764160197

Hinge Pin

14

690012366

Full Dog Screw

37

684275423

Large Sheave

5/8-11 x 1 3/4

38

684275410

Small Sheave

15

243700018

Rocking Box Assy

39

764400148

Gib (2 req’d)

16

764560170

Lock Nut

40

764440204

Belt Guard

17

739060004

Stand

42

660011147

Motor

18

764060200

Motor Bracket

43

660021326

Starter

19

764380146

Pinion Gear

44

660102151

Control Panel

20

764680178

Drive Shaft

45

684265319

Vee-Belts

21

764500202

Motor Hinge

(2 per set)

22

240700039

Bearing Bracket Assy

46

660092104

Footswitch

47

764480161

Spanner Wrench

(not shown)

When ordering Replacement Parts always give Model Number and Serial Number.

-19-

H. WEISS MACHINERY & SUPPLY

H. WEISS MACHINERY & SUPPLY

PHONE: (718) 605-0395 - www.hweiss.com