6

Burner Input Requirements

Input ratings shown on the model/serial rating plate are for

elevations up to 2,000 ft (609.6 m).

For elevations above 2,000 ft (609.6 m), ratings are reduced at a

rate of 4% for each 1,000 ft (304.8 m) above sea level (not

applicable for Canada).

Gas Supply Pressure Testing

Line pressure testing above ½ psi gauge (14" WCP)

The range and its individual manual shutoff valve must be

disconnected from the gas supply piping system during any

pressure testing of that system at test pressures greater than

½ psi (3.5 kPa).

Line pressure testing at ½ psi gauge (14" WCP) or lower

The range must be isolated from the gas supply piping system by

closing its individual manual shutoff valve during any pressure

testing of that system at test pressures equal to or less than

½ psi (3.5 kPa).

INSTALLATION INSTRUCTIONS

Unpack Range

1. Remove shipping materials, tape and protective film from

range. Keep cardboard bottom under range. Remove oven

racks and parts package from inside oven.

2. Take 4 cardboard corners from the carton. Stack one

cardboard corner on top of another. Repeat with the other 2

corners. Place them lengthwise on the floor behind the range

to support the range when it is laid on its back. Using 2 or

more people, firmly grasp the range and gently lay it on its

back on the cardboard corners.

3. Pull cardboard bottom firmly to remove.

4. Use an adjustable wrench to loosen the leveling legs.

5. Place cardboard or hardboard in front of range. Using 2 or

more people, stand range back up onto cardboard or

hardboard.

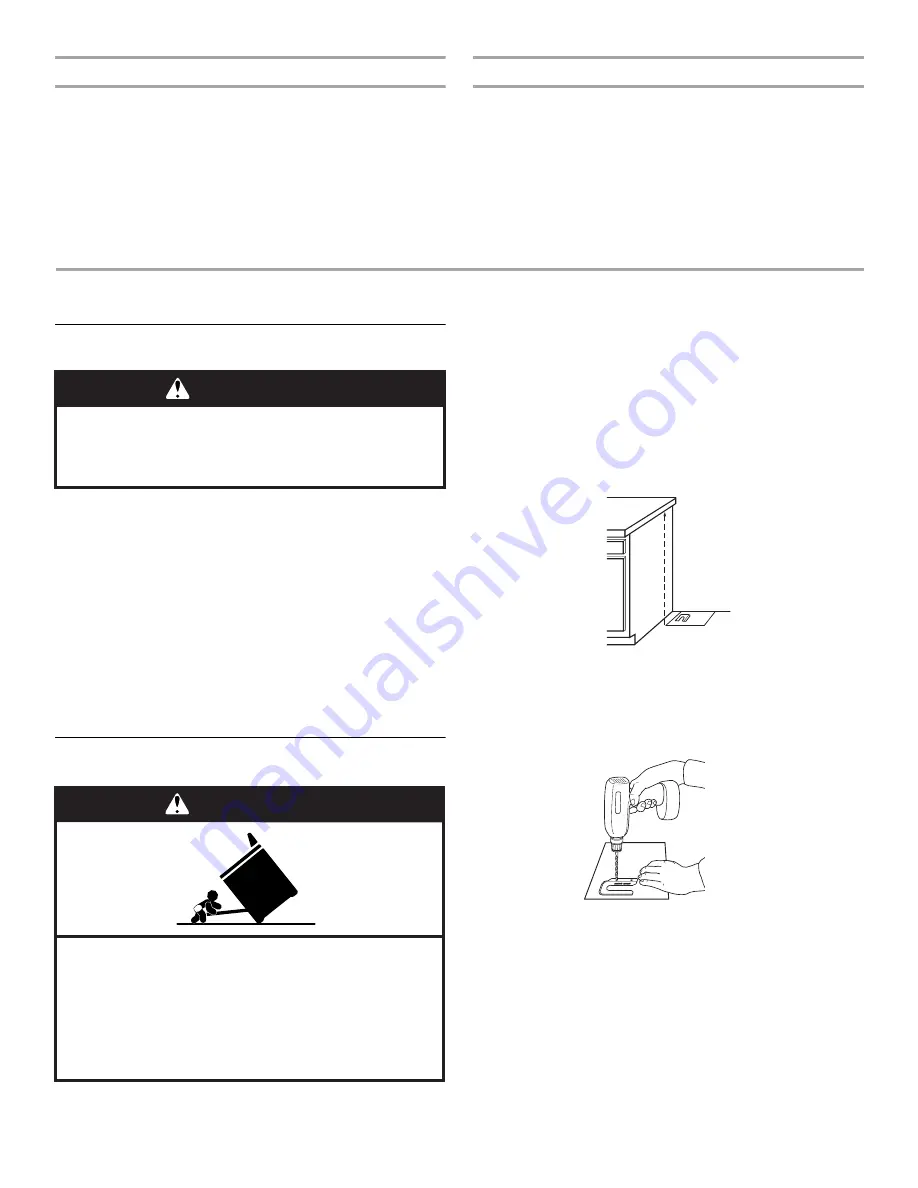

Install Anti-Tip Bracket

Contact a qualified floor covering installer for the best procedure

for drilling mounting holes through your type of floor covering.

Before moving range, slide range onto shipping base, cardboard

or hardboard.

1. Remove template from the anti-tip bracket kit (found inside

the oven cavity) or from the back page of this manual.

2. Place template on the floor in cabinet opening so that the left

edge is against cabinet and top edge is against rear wall,

molding or cabinet.

3. Tape template into place.

4. If countertop is not flush with cabinet opening edge, align

template with overhang.

If cabinet opening is wider than specified in the “Location

Requirements” section, adjust template so range will be

centered in cabinet opening.

5. To mount anti-tip bracket to wood floor, drill two

¹⁄₈

" (3.2 mm)

holes at the positions marked on the bracket template.

Remove template from floor.

To mount anti-tip bracket to concrete or ceramic floor, use a

³⁄₁₆

" (4.8 mm) masonry drill bit to drill 2 holes at the positions

marked on the bracket template. Remove template from floor.

6. Tap plastic anchors into holes with a hammer.

WARNING

Excessive Weight Hazard

Use two or more people to move and install range.

Failure to do so can result in back or other injury.

WARNING

Tip Over Hazard

A child or adult can tip the range and be killed.

Connect anti-tip bracket to rear range foot.

Reconnect the anti-tip bracket, if the range is moved.

Failure to follow these instructions can result in death

or serious burns to children and adults.

Summary of Contents for FGS326RD

Page 15: ...15 Notes ...