7

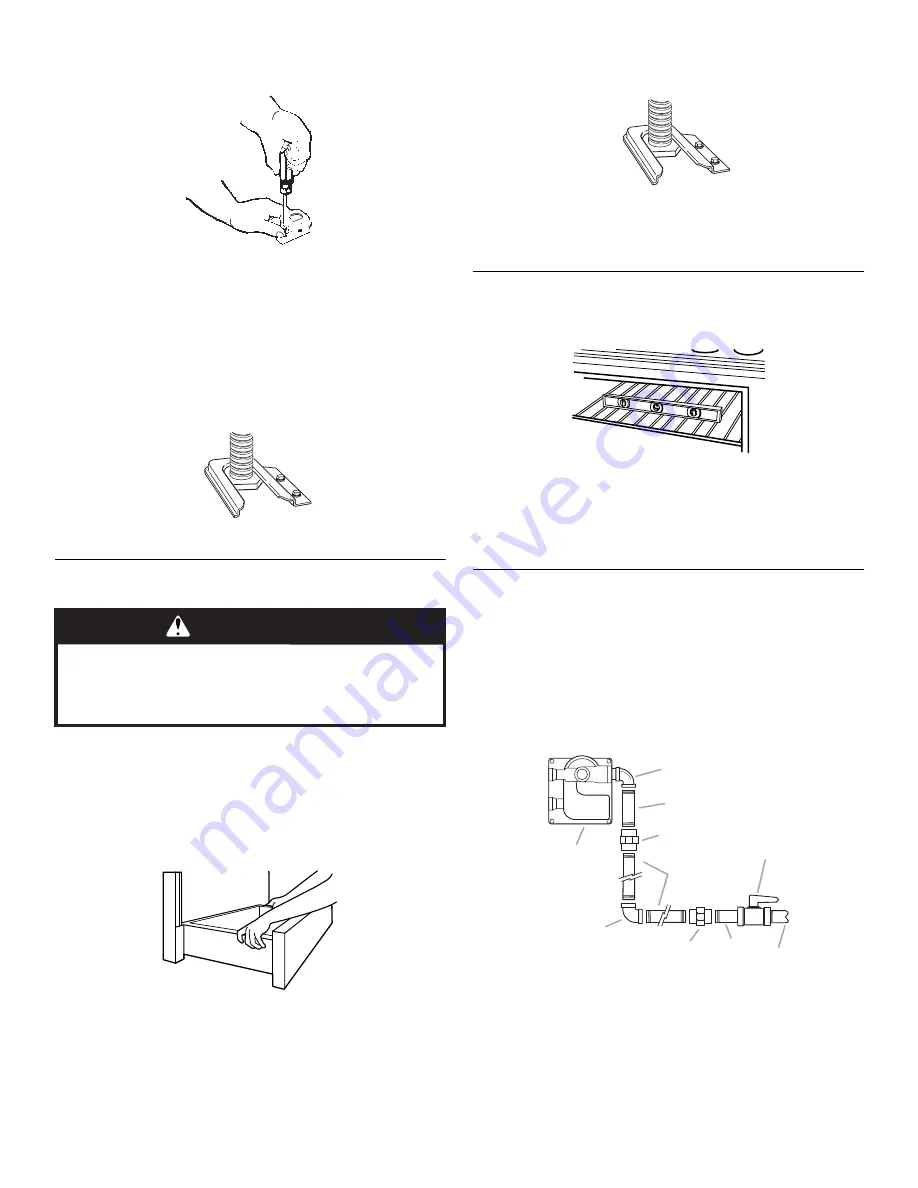

7. Align anti-tip bracket holes with holes in floor. Fasten anti-tip

bracket with screws provided.

Depending on the thickness of your flooring, longer screws

may be necessary to anchor the bracket to the subfloor.

Longer screws are available from your local hardware store.

8. Move range close to opening. Remove shipping base,

cardboard or hardboard from under range.

9. Connect power supply cord as described in the “Electrical

Connection” section.

10. Move range into final position making sure rear leveling leg

slides into anti-tip bracket.

11. Continue installing your range using the following the

installation instructions.

Verify Anti-Tip Bracket Location

1. Move range close to cabinet opening.

2. Remove cardboard or hardboard from under range. Gently

move range into its final position.

3. Pull drawer open to first stop position. Lift front of drawer to

clear white wheels in drawer guides. Remove drawer and set

it aside on a protected surface. See the Use and Care Guide

for the model drawer removal.

4. Making sure the anti-tip bracket is installed:

■

Look for the anti-tip bracket securely attached to floor.

■

Slide range back so rear range foot is under anti-tip

bracket.

5. If installing the range in a mobile home, you must secure the

range to the floor. Any method of securing the range is

adequate as long as it conforms to the standards in the

“Location Requirements” section.

Level Range

Place rack in oven. Place level on rack, first side to side; then

front to back.

If range is not level, pull range forward until rear leveling leg is

removed from the anti-tip bracket. Use

³⁄₈

" drive ratchet and

channel lock pliers to adjust leveling legs up or down until range

is level. Push range back into position. Check that rear leveling

leg is engaged in anti-tip bracket.

NOTE: Oven must be level for satisfactory baking performance.

Make Gas Connection

Typical rigid pipe connection

A combination of pipe fittings must be used to connect the range

to the existing gas line. Your connections may be different,

according to the supply line type, size and location.

1. Apply pipe-joint compound made for use with LP gas to all

pipe thread connections.

2. Using a pipe wrench to tighten, connect the gas supply to the

range.

WARNING

Excessive Weight Hazard

Use two or more people to move and install range.

Failure to do so can result in back or other injury.

A. Gas pressure regulator

B. 90° elbow (must have

½" male pipe thread)

C. Nipple

D. Union

E. Black iron pipe

F. Manual gas shutoff valve

G. ½" or ¾" gas pipe

H. Nipple

I. Union

J. 90° elbow

A

B

C

D

E

F

G

H

I

J

Summary of Contents for FGS326RD

Page 15: ...15 Notes ...