Installation

Version 1

RES-403

Page 17

You can find the exact configuration of the DIP switches in the ROPEX Application Report calculated for your par-

ticular application.

If the secondary current I

2

is less than 30A, the secondary high-current wire must be laid twice (or several times)

through the PEX-W3 or PEX-W4 current transformer (

ROPEX Application Report).

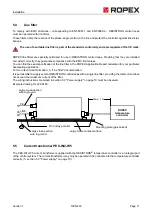

5.11.2 Configuration of the rotary coding switch for the temperature range and alloy

The settings for a temperature coefficient of 780ppm (switch position 1 and 5) are only available on controllers

manufactured as of October 2003.

If the switch is set to "9" (as of October 2005), more temperature ranges and alloys can be selected by means of

the ROPEX visualization software (

see section 6.10 "Diagnostic interface/visualization software (as of October

3

2

1

4 5

ON

OFF

1...10V

6...60V

20...120V

ON

OFF

OFF

OFF

ON

OFF

OFF

OFF

ON

30...100A

60...200A

120...400A

OFF

ON

ON

OFF

OFF

ON

DIP switch

DIP switch

1 2

U

2

I

2

3

4

5

3

2

1

4

5

4

3

O

N

O

F

F

U

(

V

)

2

1-

10

SW

IT

C

H

ON

Factory settings

2x

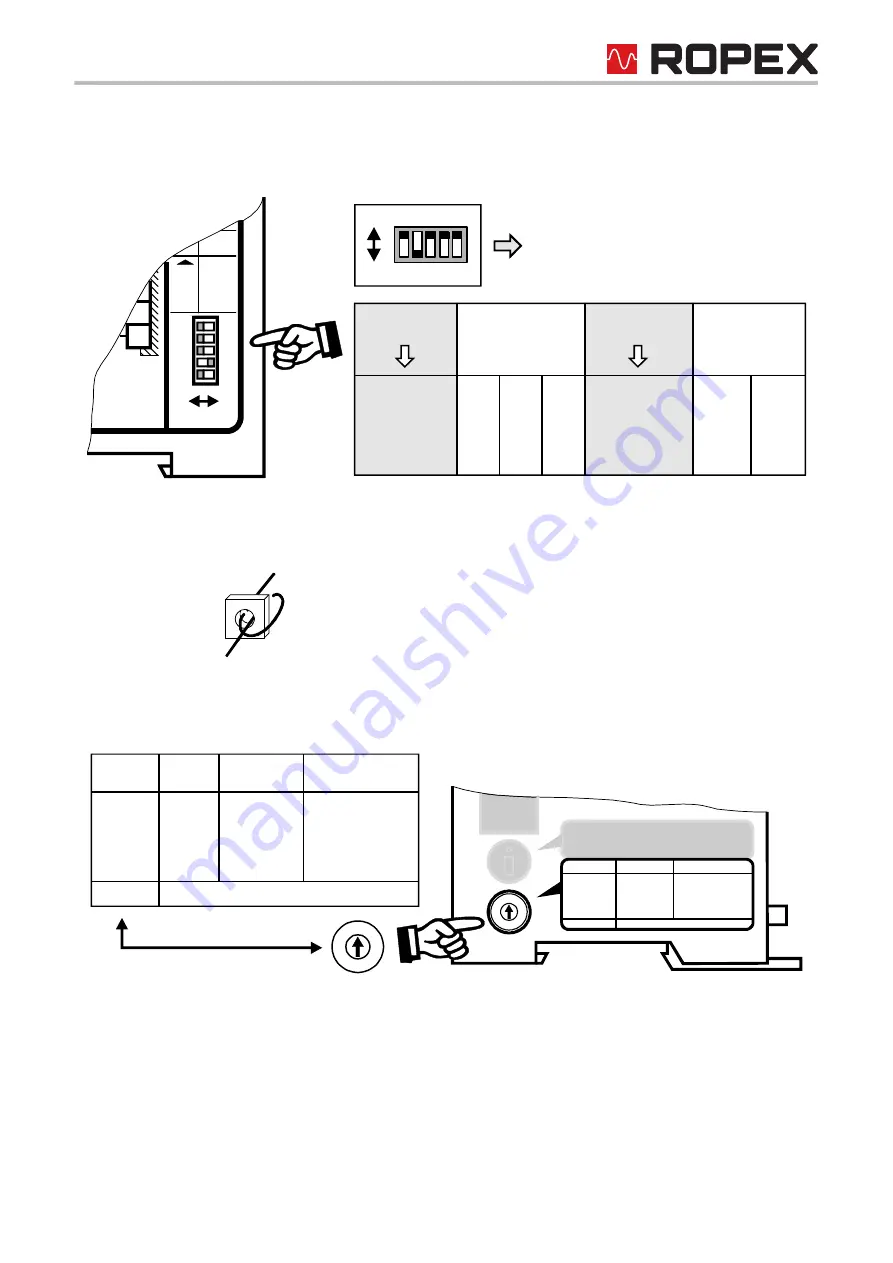

0

5

1 2

3

4

6

7

8

9

0

5

1

2

3

4

6

7

8

9

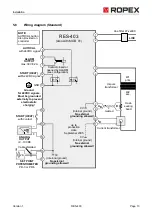

Switch

position

0

1

4

5

8

300°C

300°C

500°C

500°C

300°C

1100ppm/K

780ppm/K

1100ppm/K

780ppm/K

3500ppm/K

e.g. A20

e.g. L

e.g. A20

e.g. L

Temp.

range

Temp.

coefficient

Band

alloy

0 = Factory settings

SWITCH POS.

1

0

4

5

8

9

TEMP. RANGE

300°C

300°C

500°C

500°C

300°C

PC CONFIGURATION

ALLOY

780ppm/K

1100ppm/K

(L)

(A20)

1100ppm/K

(A20)

780ppm/K

3500ppm/K

(L)

9

PC-CONFIGURATION