Controller functions

Page 20

RES-403

Version 1

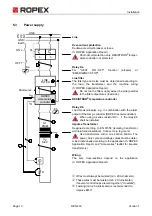

Activate the AUTOCAL function while the heatsealing band is still cold (either with the manual button on the

controller or by applying an external signal to terminals 8+13). The yellow "AUTOCAL" LED lights up the dura-

tion of the calibration process (approx. 10…15s). A voltage of app. 0VDC appears at the same time at the

actual value output (terminals 14+15). If an ATR-x is connected, it indicates 0…3°C.

When the zero point has been calibrated, the "AUTOCAL" LED goes out and a voltage of 0.66VDC (300°C

range) or 0.4VDC (500°C range) appears at the actual value output instead. If an ATR-x is connected, it must

be set to "Z".

If the zero point has not been calibrated successfully, the red "ALARM" LED blinks slowly (1Hz). In this case

the controller configuration is incorrect (

section 5.11 "Controller configuration" on page 16 and ROPEX

Application Report). Repeat the calibration after the controller has been configured correctly.

8. When the zero point has been calibrated successfully, set a defined temperature on the set point potentiometer

and activate the "START" signal (HEAT). The "HEAT" LED then lights up. The heating and control process can

be observed at the actual value output:

The controller is functioning correctly if the temperature (which corresponds to the signal change at the analog

output) has a harmonious motion, in other words it must not jump abruptly, fluctuate or deviate temporarily in

the wrong direction. This kind of behavior would indicate that the U

R

measuring wires have been wired incor-

rectly.

If an error message is displayed, please proceed as described in section 6.12 "Error messages" on page 34.

9. Burn in the heatsealing band (

section 5.12 "Replacing and "burning in" the heatsealing band" on page 18)

and repeat the AUTOCAL function.

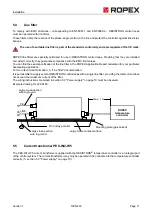

5.13.2 Restart after replacing the heatsealing band

To replace the heatsealing band, proceed as described in section 5.12 "Replacing and "burning in" the heatsealing

band" on page 18.

Always use a heatsealing band with the correct alloy, dimensions and copper-plating in order to

avoid malfunctions and overheating.

Continue with section 5.13.1 steps 4 to 9.

6

Controller functions

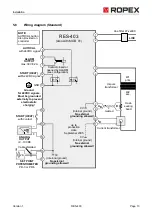

See also section 5.6 "Wiring diagram (Standard)" on page 13.

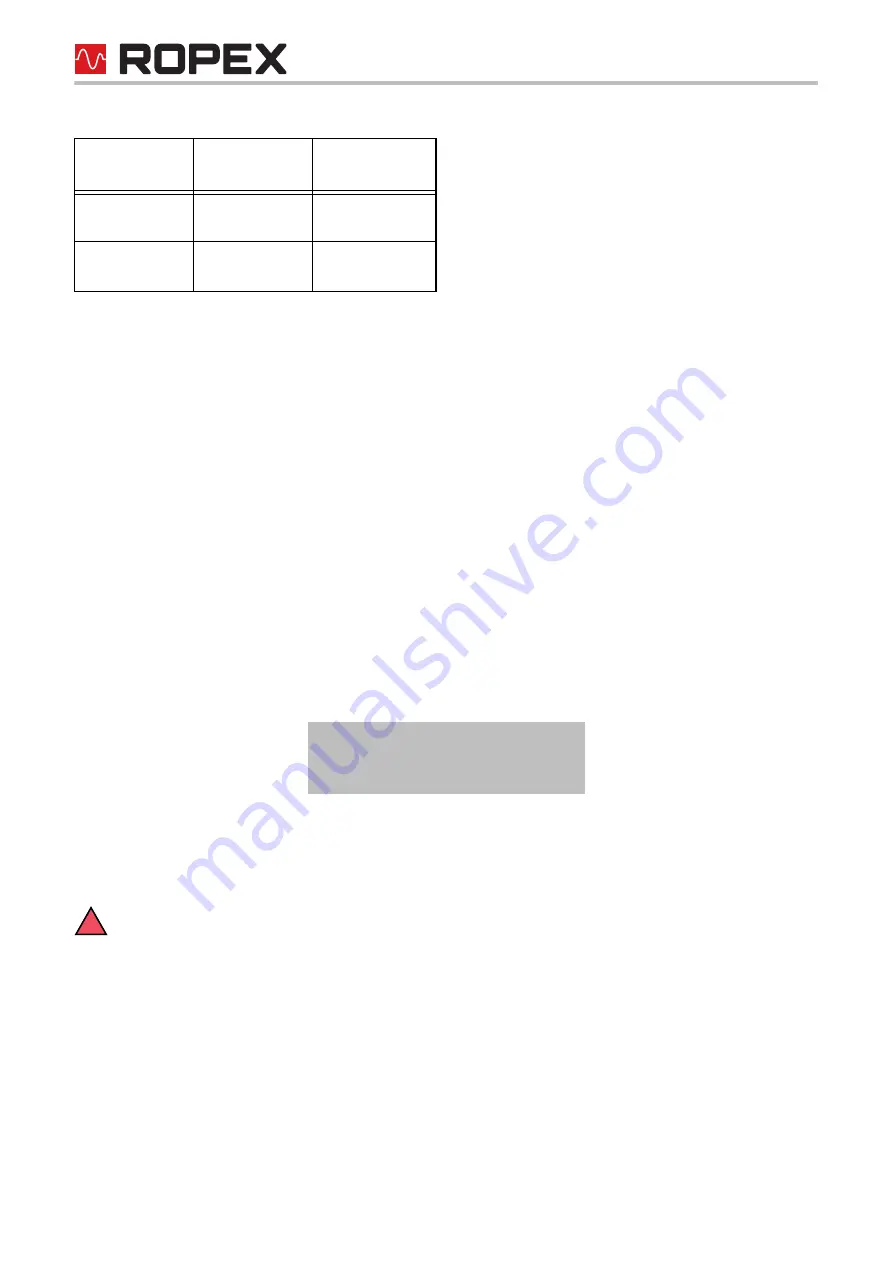

BLINKS fast

(4Hz)

OFF

Lit

Continuously

OFF

Fault diagnosis

(

sec. 6.12)

The controller is now

ready

"ALARM"

LED

"OUTPUT"

LED

ACTION

!