Installation

Version 1

RES-403

Page 9

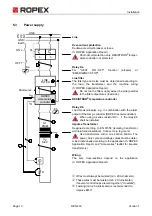

5.2

Installation steps

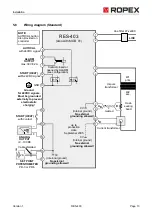

Line

Impulse

transformer

Current transformer

PEX-W2/-W3

U (prim.)

1

Heatsealing band R= f (T)

U (sec.)

2

A

F

Controller

Temperature

meter

ATR-x

Digital

potentiometer

PD-x

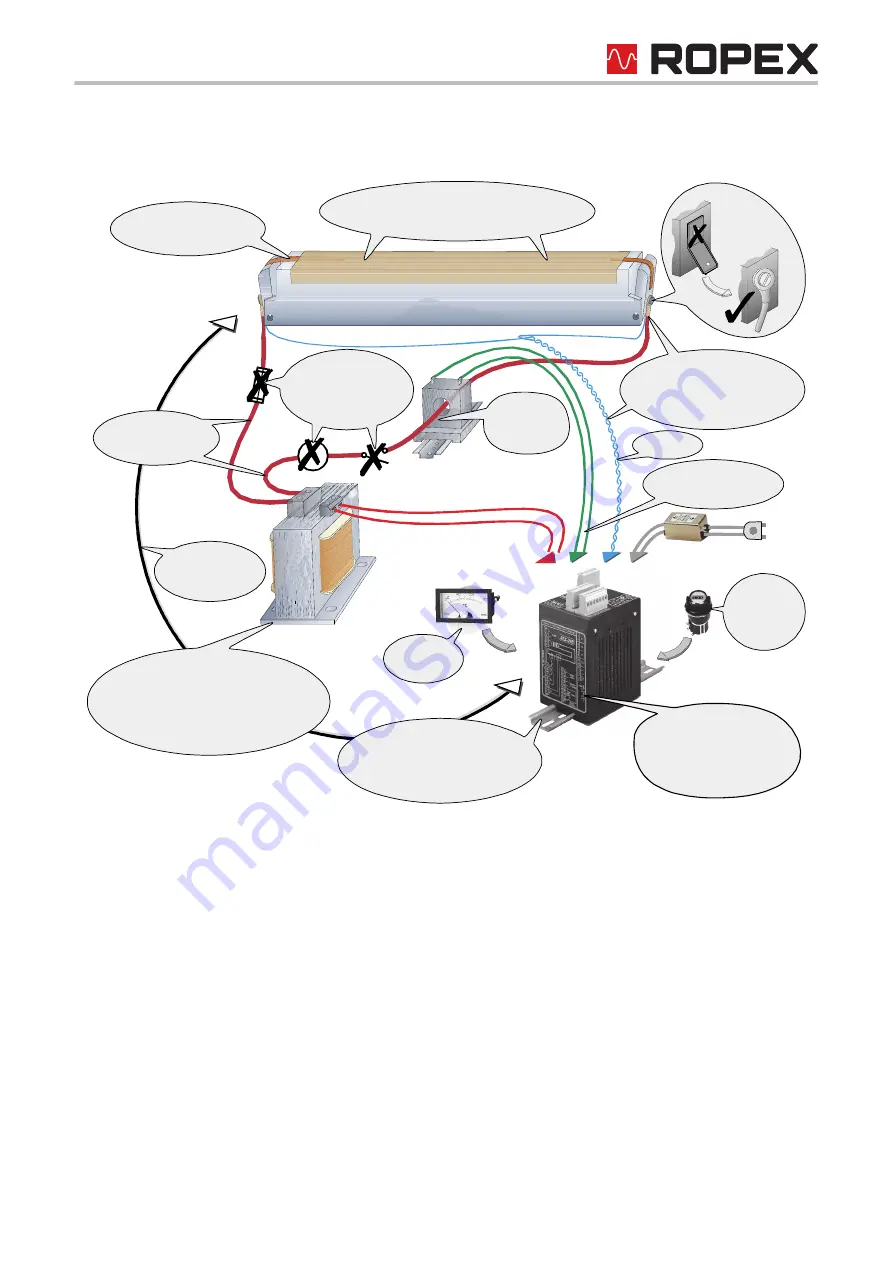

Avoid long

cables

Heatseal element

with coppered ends

Use heatseal bands with

suitable temperature coefficient

20mm clearance if several

controllers installed on

one top hat rail

Note

polarity

No additional

resistance

in secondary

circuit

Dimension

transformer correctly

- Secondary voltage

- Power

- Duty cycle

Configure

DIP switches

correctly

Sufficient wire

cross-section

No

push-on

connectors

Twisted

Current measuring

wires IR

R

Connect U measuring

wires directly to

heatsealing band ends

Line filter

LF-xx480

Note

direction

of rotation

Note

number

of turns

(up to Sept. 2005)