Seite 2

UPT-6012

Version 2

Contents

. . . . . . . . . . . . . . . . . . . . . . . . . 3

. . . . . . . . . . . . . . . . . . 3

Copyright . . . . . . . . . . . . . . . . . . . . . . . 3

Intended use . . . . . . . . . . . . . . . . . . . . 3

Heating element . . . . . . . . . . . . . . . . . 3

Impulse transformer . . . . . . . . . . . . . . 3

Current transformer PEX-W4/-W5 . . . . 4

Line filter . . . . . . . . . . . . . . . . . . . . . . . 4

Standards / CE marking . . . . . . . . . . . 4

Maintenance . . . . . . . . . . . . . . . . . . . . 5

Transportation . . . . . . . . . . . . . . . . . . . 5

2.10 Disposal . . . . . . . . . . . . . . . . . . . . . . . . 5

. . . . . . . . . . . . . . . . . . . . . . . . . . 5

. . . . . . . . . . . . . . . . . . . 6

Functional principle . . . . . . . . . . . . . . . 6

. . . . . . . . . . . . . . . . . . . . . . 7

Installation notes . . . . . . . . . . . . . . . . . 8

Installation procedure . . . . . . . . . . . . . 8

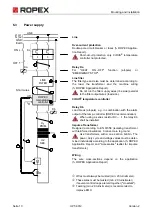

Power supply . . . . . . . . . . . . . . . . . . . 10

Line filter . . . . . . . . . . . . . . . . . . . . . . 11

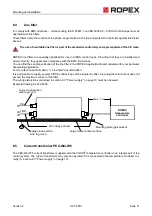

Current transformer PEX-W4/-W5 . . . 11

Wiring diagram (standard) . . . . . . . . . 13

Wiring diagram with booster connection

14

. . . . . . . . . . . . . . . . 15

View of the device . . . . . . . . . . . . . . . 15

Device configuration . . . . . . . . . . . . . 15

Heating element . . . . . . . . . . . . . . . . 17

Commissioning rules . . . . . . . . . . . . . 18

. . . . . . . . . . . . . . . . . . . . 19

LEDs and controls . . . . . . . . . . . . . . . 19

communication . . . . . . . . 20

Slave Information (ESI) . . 21

Communication protocol . . . . . . . . . . 21

Input data . . . . . . . . . . . . . . . . . . . . . . 22

Output data . . . . . . . . . . . . . . . . . . . . 24

Object dictionary . . . . . . . . . . . . . . . . 28

Integrated web server . . . . . . . . . . . . 38

Undervoltage detection . . . . . . . . . . . 42

8.10 Temperature meter (actual value output)

8.11 Booster connection . . . . . . . . . . . . . . 44

8.12 USB interface for visualization software

® . . . . . . . . . . . . . . . . . . . . . . . 44

AUTOCAL . . . . . . . . . . . . . . . . . . . . . 45

8.17 Built-in clock (date and time) . . . . . . . 45

8.18 System monitoring / alarm output . . . 46

8.19 Error messages . . . . . . . . . . . . . . . . . 47

8.20 Fault areas and causes . . . . . . . . . . . 51

. . . . . . . . . . . . . . . . . . . . . 52

. . . . . . . . . . . . . . . . . . . . . . 53

. . . . . . . . . . . . . . . . . . . . . . . . 55

. . . . . . . . . . . . . . . . 55

. . . . . . . . . . . . . . . . . . . . . . . . 56

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58