Device functions

Seite 46

UPT-6012

Version 2

The built-in clock can be set and read out in the ROPEX visualization software (

section 8.12 "USB interface for

visualization software ROPEXvisual

" on page 44) or using the acyclic services of the EtherCAT

®

interface. The

date and time can be read out but not set via the integrated server.

A maintenance-free capacitor is used to operate the clock. There is no battery that has to be replaced every now

and then.

The controller must remain switched on for at least three hours to make sure the clock’s capacitor is fully charged.

When the controller is switched off, the fully charged capacitor can keep the clock running for approximately 2…4

weeks. If the controller is switched off for longer, the date and time will have to be set again. You can do this in

the ROPEX visualization software (

section 8.12 "USB interface for visualization software ROPEXvisual

page 44) or using the acyclic services of the EtherCAT

®

interface.

The capacitor is not charged when it leaves the factory. When the controller is started up, you must set the clock

if you want error messages to be saved in the data memory (

section 8.16 "Data memory for error messages

and AUTOCAL" on page 45) together with their date and time of occurrence.

The controller can also be operated without the clock. In this case, the dates and times that are saved in the data

memory will be invalid (

section 8.16 "Data memory for error messages and AUTOCAL" on page 45) . However,

this has no effect on the temperature control functions.

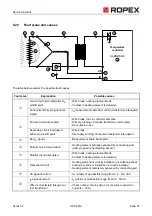

8.18

System monitoring / alarm output

To increase operational safety and avoid faulty heatsealing, this controller incorporates special hardware and soft-

ware features to facilitate selective error detection and diagnosis. Both the external wiring and the internal system

are monitored.

These features significantly assist the operator in identifying the cause of abnormal situations.

A system fault is reported or differentiated by means of the following indications.

A.)

Red "ALARM" LED on the controller with three states:

1.

Blinking fast (4 Hz):

The "AUTOCAL" function should be executed (error codes 104…106, 211, 302, 303).

2.

Blinking slowly (1Hz):

The system configuration is incorrect and the zero calibration ("AUTOCAL" function) was unsuccessful

(

section 7.2 "Device configuration" on page 15). This corresponds to error codes 111…114).

3.

Lit continuously:

A fault is preventing the system from starting (error codes 101…103, 107, 108, 201…203, 304, 305, 307, 308,

9xx).

As a rule, this refers to an external wiring fault.

B.)

Alarm relay (relay contact terminals 12+13+14):

This relay is set at the factory as follows:

•

DE-ENERGIZED

in operating states A.1 and A.2 but energized if a START signal is present in one of these

states.

•

ENERGIZED

in operating state A.3.

If the alarm relay has the opposite configuration to the factory setting (

section 7.2.4 "Configuration of the alarm

relay" on page 17), these states are reversed.

C.)

Error code indicated via the EtherCAT

®

protocol:

If an error occurs, the AL bit is set and possibly also the WA bit. The error code is contained in the third word at

bit positions 0…9 (