Installation

Page 16

RES-403

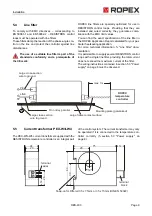

5.12.2 Replacing the heatsealing band

All power supply leads must be disconnected

from the RESISTRON temperature controller

in order to replace the heatsealing band.

The heatsealing band must be replaced in

accordance with the instructions provided by

the manufacturer.

Each time the heatsealing band is replaced, the zero

point must be calibrated with the AUTOCAL function

while the band is still cold, in order to compensate pro-

duction-related resistance tolerances. The burn-in pro-

cedure described above should be performed for all

new heatsealing bands.

5.13

Startup procedure

Please also refer to section 1 "General information" on

page 3 and section 2 "Application" on page 4.

Installation and startup may only be per-

formed by technically trained, skilled per-

sons who are familiar with the associated risks and

warranty provisions.

5.13.1 Initial startup

Prerequisites: The controller must be correctly installed

and connected (

ª

section 5 "Installation" on page 5).

Proceed as follows to start up the controller for the first

time:

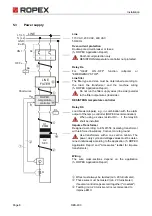

1. Switch off the line voltage and verify that all circuits

are de-energized.

2. The supply voltage specified on the nameplate of

the controller must be identical to the line voltage

that is present in the plant or machine. The line fre-

quency is automatically detected by the tempera-

ture controller in the range from 47…63Hz.

3. In the case of controllers manufactured up to Sep-

tember 2005, the settings of the DIP switches on the

controller are indicated in the ROPEX Application

Report and depend on the heatsealing band that is

used (section 5.11 "Controller configuration" on

page 13).

4. Make sure that no START signal is activated.

5. Switch on the line voltage.

6. When the voltage is switched on, the yellow

"AUTOCAL" LED lights up for approximately 0.3

seconds to indicate that the controller is being

powered up correctly.

As of SW-Revision 106:

If the red "ALARM" LED lights up for 0.3s in

addition to the yellow "AUTOCAL" LED when the

voltage is switched on, the configuration of this

controller has been changed in the visualization

software (

ª

section 6.10 "Diagnostic interface/

visualization software (as of October 2005)" on

page 25). In order to avoid malfunctions, please

check the controller configuration before

continuing the startup procedure.

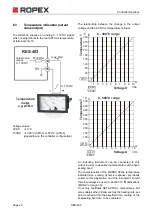

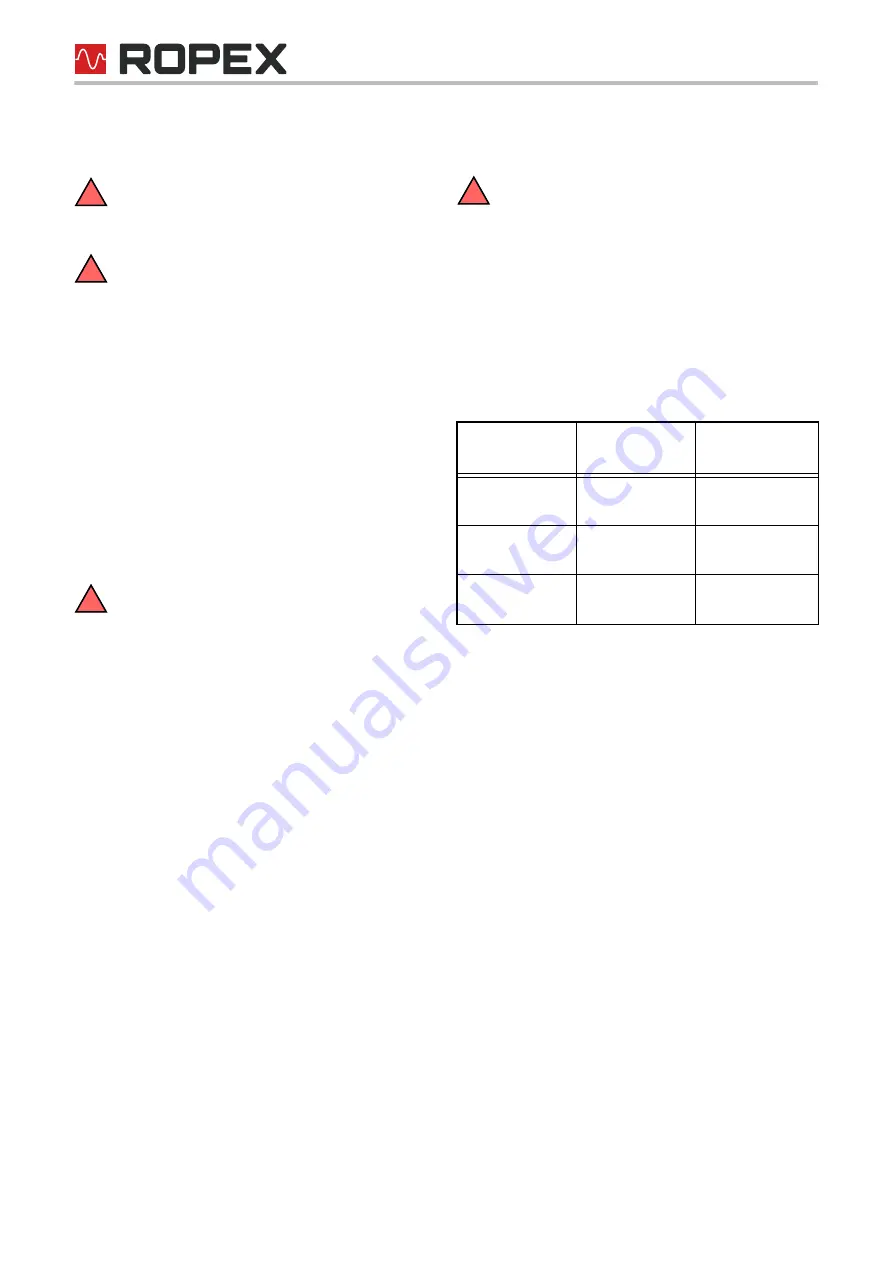

7. One of the following states then appears:

Activate the AUTOCAL function while the heatse-

aling band is still cold (either with the manual button

on the controller or by applying an external signal to

terminals 8+13). The yellow "AUTOCAL" LED lights

up the duration of the calibration process (approx.

10…15s). A voltage of app. 0VDC appears at the

same time at the actual value output (terminals

14+15). If an ATR-x is connected, it indicates

0…3°C.

When the zero point has been calibrated, the

"AUTOCAL" LED goes out and a voltage of

0.66VDC (300°C range) or 0.4VDC (500°C range)

appears at the actual value output instead. If an

ATR-x is connected, it must be set to "Z".

If the zero point has not been calibrated suc-

cessfully, the red "ALARM" LED blinks slowly (1Hz).

In this case the controller configuration is incorrect

(

ª

section 5.11 "Controller configuration" on

page 13 and ROPEX Application Report). Repeat

the calibration after the controller has been confi-

gured correctly.

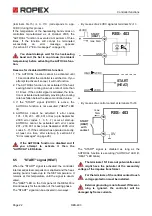

8. When the zero point has been calibrated suc-

cessfully, set a defined temperature on the set point

potentiometer and activate the "START" signal

(HEAT). The "HEAT" LED then lights up. The hea-

ting and control process can be observed at the

!

!

!

"ALARM"

LED

"OUTPUT"

LED

ACTION

OFF

Short pulses

every 1.2s

Go to 7

BLINKS fast

(4Hz)

OFF

Go to 7

Lit

Continuously

OFF

Fault diagnosis

(

ª

sec. 6.12)

!