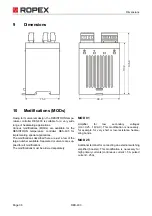

Controller functions

RES-403

Page 25

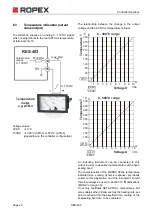

6.9

Heatup timeout

(as of October 2005)

An additional heatup timeout can be activated in the

ROPEX visualization software (

ª

section 6.10 "Dia-

gnostic interface/visualization software (as of October

2005)" on page 25).

This timeout starts when the START signal is activated.

The RES-403 then monitors the time required for the

ACTUAL temperature to reach 95% of the SET tempe-

rature. If this time is longer than the parameterized

time, the corresponding error code (304) is indicated

and the alarm relay is switched (

ª

section 6.12 "Error

messages" on page 26).

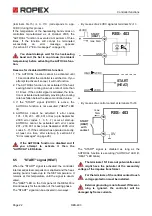

6.10

Diagnostic interface/visualization

software (as of October 2005)

An interface with a 6-pole Modular Jack (RJ-12) is pro-

vided for system diagnostics and process visualization.

This interface allows a data connection to be set up to

the ROPEX visualization software using the ROPEX

communication interface CI-USB-1.

Only a ROPEX comunication interface is

allowed to be connected to the diagnostic

interface. Connecting another device (e.g. a

telephone cable) could result in malfunctions or

damage to the controller.

The ROPEX visualization software is described in a

separate document.

6.11

System monitoring/alarm output

To increase operating safety and to avoid faulty heatse-

aling, this controller incorporates special hardware and

software features that facilitate selective fault detection

and diagnosis. Both the external wiring and the internal

system are monitored.

These features assist the operator in identifying the

cause of abnormal operations.

A system fault is reported or differentiated by means of

the following indications.

A.)

Red "ALARM" LED on the controller

three states:

1.

Blinks fast (4Hz)

The AUTOCAL function should be executed (error

codes 104…106, 211, 302, 303; up to September

2005: error codes 8+9).

2.

Blinks slowly (1Hz)

The system configuration is incorrect and the zero

calibration (AUTOCAL function) was unsuccessful

(

ª

section 5.11 "Controller configuration" on

page 13). It corresponds to error codes 110…114

(up to September 2005: error codes 10…12).

3.

Lit continuously:

This indicates that a fault is preventing the controller

from being started (error codes 101…103, 107, 108,

201…203, 307, 308, 801, 9xx; up to September

2005: error codes 1…7).

As a rule, it refers to an external wiring fault.

B.)

Alarm relay (relay contact terminals 5+6):

This contact is set in the factory as follows:

•

OPEN

in operating states A.1) and A.2), but closed

if a "START" signal is activated in one of these

states.

•

CLOSED

in operating state A.3)

If the alarm relay is configured opposite to the factory

setting (

ª

section 5.11.3 "Configuration of the alarm

relay" on page 15), these states are reversed.

Set

95% of Set

Actual value

Time

Heatup time

Alarm

304

Timeout

0

5

1 2

3

4

6

7

8

9

DI

A

G

!