Controller functions

Page 26

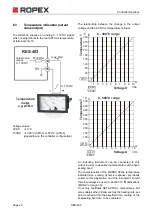

RES-403

C.)

Error code output via the 0

…

10VDC analog

output (terminals 14+15):

Since a temperature indication is no longer neces-

sary if a fault occurs, the analog output is used to

display error messages in the event of an alarm.

13 voltage levels (up to September 2005: 12 voltage

levels) are offered for this purpose in the 0…10VDC

range, each of which is assigned an error code

(

ª

section 6.12 "Error messages" on page 26).

If a state that requires AUTOCAL occurs – or if the con-

troller configuration is not correct – (error codes

104…106, 111…114, 211, 302, 303; up to September

2005: error codes 8…12), the signal at the analog

output jumps back and forth at 1Hz between the

voltage value which corresponds to this error and the

end of the scale (10VDC, i.e. 300°C or 500°C). If the

"START" signal is activated in one of these states, the

voltage value does not change any more.

An alarm can only be reset by switching the

controller off and then on again.

Invalid error messages may appear when the

controller is switched off owing to the unde-

fined operating state. This must be taken into

account when they are evaluated by the higher-

level controller (e.g. a PLC) in order to avoid false

alarms.

6.12

Error messages

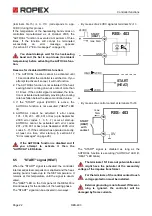

The table below shows how the analog voltage values

correspond with the faults that have occurred. It also

describes the fault and the required corrective action.

The error messages are listed in two separate tables for

controllers "up to September 2005" and "as of October

2005". The block diagram in section 6.13 "Fault areas

and causes" on page 31 permits each fault to be

cleared quickly and efficiently.

13 voltage levels for fault diagnostics appear at the

actual value output of all controllers manufactured as of

October 2005. The error messages are differentiated

even more finely in the controller. The error codes

described below can be displayed with the ROPEX

visualization software (

ª

section 6.10 "Diagnostic

interface/visualization software (as of October 2005)"

on page 25) to facilitate troubleshooting.

If the actual value output is evaluated in order

to identify an error message - in the higher-

level controller, for instance - the tolerance window

must be adjusted to prevent it from being incor-

rectly interpreted. Please note the tolerances of the

actual value output (

ª

section 8 "Technical data"

on page 34).

!

!

!