Principle of operation

RES-403

Page 5

• Pouch, filling and sealing machines

• Film wrapping machines

• Pouch-making machines

• Group packaging machines

• etc.

3

Principle of operation

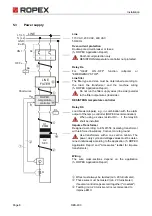

The resistance of the heatsealing band, which is tem-

perature-sensitive, is monitored 50x per second (60x at

60Hz) by measuring the current and voltage. The tem-

perature calculated with the help of these measure-

ments is displayed and compared with the set point.

The primary voltage of the impulse transformer is adju-

sted by phase-angle control, if the measured values

deviate from the set point. The resulting change in the

current through the heatsealing band leads to a change

in the band temperature and thus also its resistance.

This change is measured and evaluated by the RESI-

STRON temperature controller.

The control loop is closed: ACTUAL temperature = SET

temperature. Even minute thermal loads on the heatse-

aling band are detected and can be corrected quickly

and precisely.

A highly high response thermo-electric control loop is

formed which is highly accurate because purely elec-

trical variables are measured at a high sampling rate. A

high secondary current can be controlled because

power is controlled on the primary side of the trans-

former. This allows optimum adaptation to the load and

to the required dynamic range despite the exceptionally

compact dimensions of the controller.

4

Traits of the controller

• Very simple operation thanks to AUTOCAL, the

automatic zero calibration function.

• Good dynamic response of the control system

thanks to AUTOTUNE, which adapts automatically

to the controlled system.

• High precision thanks to further improved control

accuracy and linearization of the heatsealing band

characteristic.

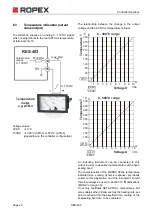

• High flexibility: The AUTORANGE function (as of

October 2005) covers a secondary voltage range

from 0.4V to 120V and a current range from 30A to

500A.

• Automatic adjustment to the line frequency in the

range from 47Hz…63Hz.

• Increased protection against dangerous conditions,

such as overheating of the heatsealing band.

The ACTUAL temperature of the heatsealing band is

supplied to an analog 0…10VDC output. The real heat-

sealing band temperature can thus be displayed on an

external temperature indicator (e.g. ATR-x).

The RESISTRON temperature controller RES-403 fea-

tures an integrated fault diagnosis function, which tests

both the external system (heatsealing band, wiring etc.)

and the internal electronics and outputs a selective

error message in case of a fault.

To increase operational safety and interference immu-

nity, all 24VDC logic signals are electrically isolated

from the controller and the heating circuit.

Coding switches on the temperature controller itself

can be used to adapt to different heatsealing band

alloys (Alloy-20, NOREX etc.) and set to the required

temperature range (0…300°C, 0…500°C etc.).

The compact design of the RESISTRON temperature

controller RES-403 and the plug-in connections make

this controller easy to install.

5

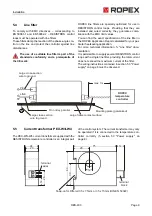

Installation

ª

See also section 1 "General information" on page 3.

Installation and startup may only be per-

formed by technically trained, skilled per-

sons who are familiar with the associated risks and

warranty provisions.

!