Factory settings

Version 2

RES-5008

Page 55

4. In the meantime, the electrician checks and moves the wires (high-current cables, measuring cables, ...). All

plugs and contact blocks must also be checked by tapping them.

5. As soon as the displayed or measured temperature changes suddenly, the cause for the loose contact will be

found.

If the controller goes into “fault” immediately, when a continuous START signal is generated, we recommend the

following procedure:

1. The machine operator observes the displayed or measured temperature in the nonoperating state.

2. In the meantime, the electrician checks and moves the wires (high-current cables, measuring cables, ...). All

plugs and contact blocks must also be checked by tapping them.

Remarks:

More time is required for this in the non-operating state, as measurements only take place every 1.2 seconds.

3. As soon as the displayed or measured temperature changes suddenly, the cause for the loose contact will be

found.

If the alarm cannot be reset, the above-mentioned procedures cannot be used. In this case we recommend that

you minimise your control system, e.g. to place a new sealing tool directly in front of the control cabinet and to

connect it with new, short cables. Then carry out the AUTOCAL function and repeat the five steps listed above to

locate the loose contact.

If the measures described has not led to success, please contact us directly (

) and send the fol-

lowing information to:

• Date and number of the application report and, if applicable, project name, as well as the used page and

column.

• Actual implementation of the sealing application in the machine if this deviates from the application report.

• Relevant pages from its electrical circuit diagram, possibly information on plugs and connections.

• The error numbers that have occurred (can be read e.g. by using the ROPEX visualisation software).

• Description of the error and measures taken so far.

• Serial number and production date of the temperature controller.

10

Factory settings

The RESISTRON

®

Temperature Controller RES-5008 is configured as follows from the factory:

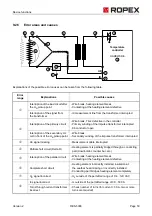

Rotary encoder

switch

for

Heating element alloy

and

Temperature range

Heating element alloy: Alloy A20

Temperature range: 300 °C

Rotary encoder switch: Position “0”

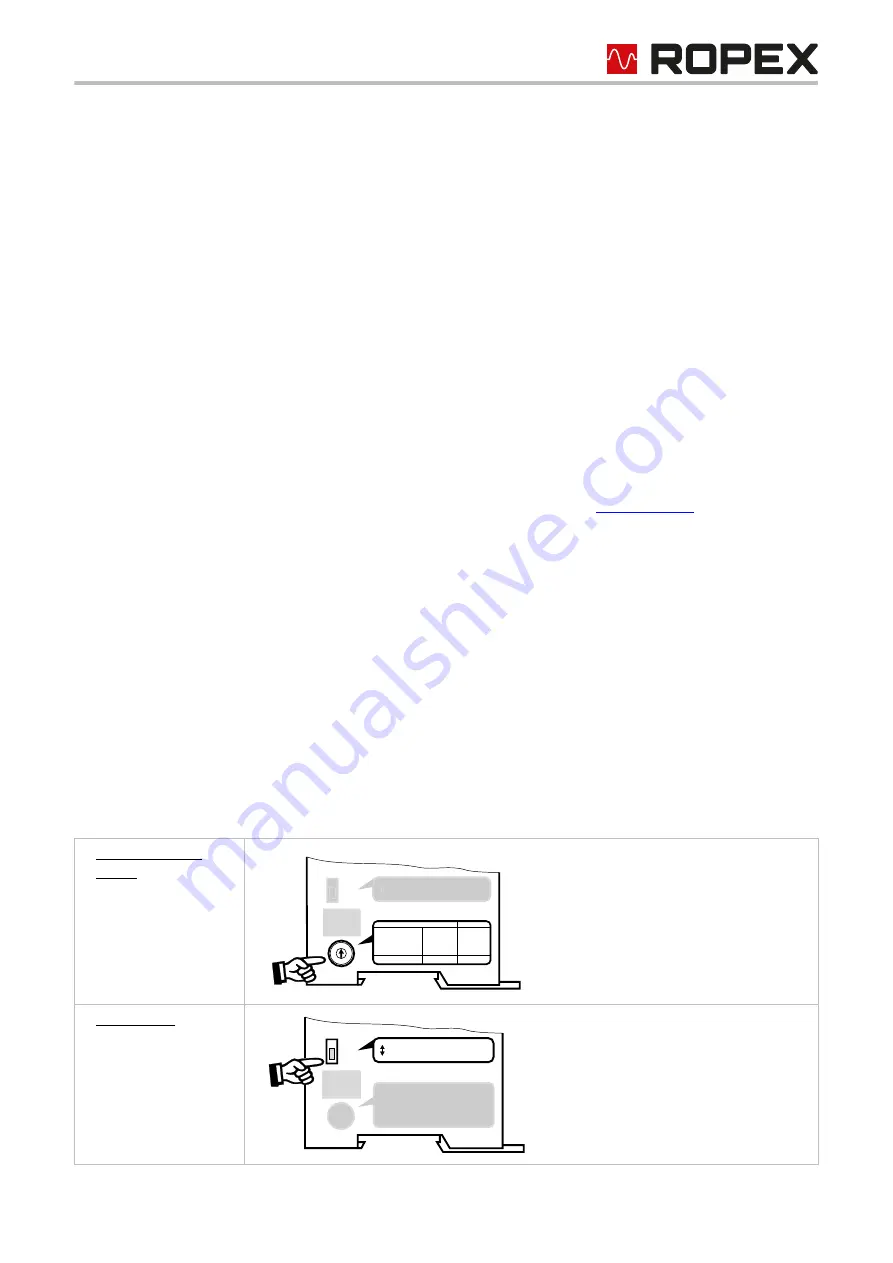

Slide switch

for

Alarm relay

Alarm relay active in case of alarm

0

5

1 2

3

4

6

7

8

9

AU

X

CONF

IG

UR

ATI

ON

ALARM

OU

TP

UT

ENER

GIZ

ED

(

)

A T

ALARM

-

DE

ENER

GIZ

ED

SWIT

CH

P

OS.

1

0

4

5

8

9

TEM

P. RAN

GE

300°C

300°C

500°C

500°C

300°C

PC

C

ONFI

GUR

A TI

ON

TEM

P. C

OEF

FIC

IE

NT

780p

pm

/K

1 100

ppm

/K

(L)

(A

20)

1 100

ppm

/K

(A

20)

780p

pm

/K

3500p

pm

/K

(L)

0

5

1 2

3

4

6

7

8

9

AU

X

CONF

IG

URATI

ON

ALARM

O

UTP

UT

ENER

GIZ

ED

(AT

AL

ARM )

DE-E

NERG

IZ

ED