Product description

Page 10

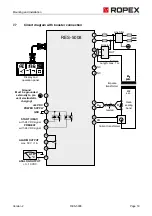

RES-5008

Version 2

• Electro-technical data as the basis for the electrical components

• Parts list and schematic diagram for the necessary components

• Instructions and recommendations for mechanical design

• Instructions for installing the cables and components

To receive a ROPEX application report, please fill out our

completely. When you send the completed

questionnaire, a new window opens with a reference number (e.g. AR1234) and a link to the questionnaire you

created. This link enables you to reopen the questionnaire for your next inquiry. We therefore recommend that you

save the link and the reference number.

Subsequently, you will have the opportunity to send us further information on this questionnaire, such as for

example, technical descriptions or pictures.

The ROPEX application team then creates the application report based on the data you have entered. If relevant

data is missing, we will contact you to clarify the open points. As soon as the application report has been created,

you will receive it by email. We will then send you an offer for the components listed in the application report.

If you cannot judge whether your material can be sealed or what cycle rate is possible, we can also create sealing

samples for you. We will then use our system and your material to check the possibility for sealing and incorporate

the findings into the application report.

In this case you are welcome to contact

. Your request will then be passed on to the application

team to coordinate the next steps.

5

Product description

5.1

Use

This RESISTRON

®

Temperature Controller is part of the “RES-5000 Series”. All RESISTRON

®

Temperature

Controllers are used for regulating the temperature of heating elements. Heating elements are used in a wide

variety of foil sealing processes.

The most common heating elements include:

• flat bands (straight and contoured)

• tapered bands

• beaded bands

• cutting wires (straight and contoured)

• heated sealing and cutting knifes

• soldering brackets

The main application area is sealing or cutting of thermoplastics using the thermal impulse process.

The most common application areas are:

• vertical and horizontal flow wrapping machines (VFFS and HFFS)

• bagging, filling and sealing machines

• film-wrapping machines

• bag-production machines

• group packaging machines

• film sealing devices

• spout and tube sealing

• and much more.