Requirements for the functioning of the control system

Version 2

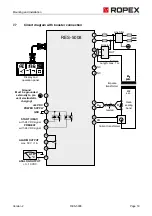

RES-5008

Page 9

• A very important design measure is copper-coating or silver-coating of the heating element ends. The thermal

characteristics change in this range through coating of the heating element ends. As a result, the ends remain

cold, which permits exact temperature control and increases the useful life of the heating element and the wear

materials (e.g. silicone underlayment, heating band cover).

4.2

Impulse transformer

A suitable impulse transformer is required for the control loop to function properly. The power and the secondary

voltage must be laid out for the control loop. According to EN 61558 or UL 5058, the transformer must be laid out

as an isolating transformer with reinforced insulation and have a single-chamber structure. Adequate protection

against accidental contact must be provided when assembling the impulse transformer. The relevant national

installation and construction regulations must be observed, while doing so. Water, cleaning solutions and / or con-

ductive liquids may not come into contact with the impulse transformer.

The cable cross-sections must be designed as per the ROPEX application report.

Incorrect assembly and installation of the impulse transformer impair electrical safety.

The terminals on the pulse transformer must be checked and tightened regularly.

4.3

Current transformer

The current transformer appropriate for RESISTRON

®

Temperature Controller is part of the control system.

In order to avoid malfunctions, only the original ROPEX current transformers or ROPEX monitoring current trans-

formers may be used.

The current transformer may be operated only if it is correctly connected to the RESISTRON

®

Temperature Con-

troller (See Chapter “Start-up”). The safety-related information in the “Mains connection” chapter must be

observed. External monitoring modules can be used to increase operational safety furthermore. Monitoring mod-

ules are not part of the standard control system and are described in separate documentation.

4.4

Line filter

ROPEX offers line filters in various performance classes. The ROPEX Application Report lists the suitable line

filter, which can be ordered.

For fulfilling the guidelines mentioned in the section 1.5 "DECLARATION OF CONFORMITY" on page 6, it has

been stipulated to use an original ROPEX line filter. Installation and connection must be carried out in accordance

with the instructions in the "Mains connection" chapter or the separate documentation for the respective line filter.

4.5

Application report

The ROPEX application report contains all the important technical information on your sealing applications. If you

have several applications in a system, these are displayed in the application report on different pages and col-

umns. This allows you to easily differentiate between them. The application report is created individually by

the ROPEX application team and is the basis for the electro-technical design of your sealing applications.

The ROPEX application report contains the following information among other things:

• List of the different heating element dimensions

• Specification of the necessary temperature coefficient