INSTALLATION AND OPERATION

The HPS 1000 Droplight System is a sturdy assembly designed to withstand the harsh

demands of underwater operation. However, a few precautions are recommended in

order to prevent damage and assure trouble-free operation during the life of the

equipment.

NOTE:

All ROS, Inc. products are thoroughly tested and inspected prior to

shipment. However, damage may occur during transit. After unpacking the

equipment, carefully inspect it for any sign of damage. If damage is detected a

claim should be submitted to the freight carrier, with a copy to ROS, Inc.

After the initial inspection, connect and operate the equipment as instructed in the

following section. If the equipment fails to operate, please contact the Customer

Service Manager at ROS, Inc.

OPERATIONAL CHECK

After unpacking, an operational check should be made prior to use of the HPS-1000.

Plug in 120 VAC power for a brief period of time (less than one minute) to verify the light

will operate.

CAUTION

THE LAMP IS DESIGNED FOR IN WATER USE ONLY. DO NOT BURN IN AIR FOR

MORE THAN 5 MINUTES.

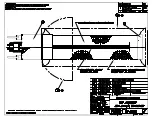

INSTALLATION

The HPS-1000 Droplight can be mounted and operated in any position underwater. For

most fuel pool and reactor vessel applications, it is simply lowered by the

interconnecting cable to the desired position.

In the optional cable management system the ballast power supply and cable reel are

mounted to a high-density polyethylene platform. The HPS-1000 Droplight is simply

reeled in or out to the desired location.

Either configuration allows for use of the standard reflector or lower core plate flow hole

side looking reflector.

80-06003B 05APR04

4