REMOTE OCEAN SYSTEMS

SEASTAR OPERATION AND MAINTENANCE MANUAL

10-01313 REV D

29

3.

Inspect the outside of the light for signs of a short, such as browned, blackened or melted components.

Disconnect the power connector and inspect for signs of a short.

4.

Verify the power cable is securely connected to the light.

5.

Verify the power is turned on and any dimmers are set high enough to allow light output.

6.

Verify the DC analog dimming signal or serial dimming is set high enough to allow light output.

7.

Verify the power supply is outputting the expected voltage: 110 to 130VAC or 20 to 26 VDC.

8.

Inspect the light for signs of water intrusion.

WARNING

Disconnect the Seastar from power prior to servicing or troubleshooting internal

components.

Seastar contains high voltages and currents, and should be serviced only by

trained technicians.

9.

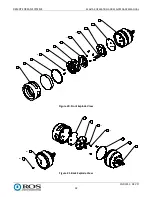

If the problem has not been identified and resolved, open the light (5.2.1).

10.

Check for loose or disconnected wires.

11.

Disconnect the driver input connector from driver board, check the connector for signs of a short.

a.

Use volt meter to check for resistance on the driver board input pins (see Figure 19).

i.

Pin 1 to pin 2: open circuit

ii.

Pin 2 to pin 3: open circuit

iii.

Pin 3 to pin 4: open circuit

iv.

Pin 4 to pin 5: open circuit

12.

Check for broken components or signs of a short.

a.

Use volt meter to check fuse (F1) for continuity. If resistance is greater than 3 ohms, the fuse

has been tripped and there may be a short circuit somewhere in the driver board or LED array.

b.

Use volt meter to check for isolation

i.

Check resistance between Output 1 pin and PCB mounting screw, resistance should read

open circuit.

ii.

Check resistance between Output 2 pin and PCB mounting screw, resistance should read

open circuit.

iii.

Check resistance between Output 3 pin and PCB mounting screw, resistance should read

open circuit.