VLT

®

8000 AQUA

■

General information about electrical installation

■

High voltage warning

The voltage of the AFD is dangerous

whenever the equipment is connected to

line. Incorrect installation of the motor

or the AFD may cause damage to the equipment,

serious personal injury or death. Consequently,

the instructions in this manual, as well as national

and local safety regulations, must be complied

with. Touching the electrical parts may be fatal

- even after disconnection from line:

Using VLT 8006-8062, 200-240 V wait at

least 15 minutes

Using VLT 8006-8072, 380-480 V wait at

least 15 minutes

Using VLT 8102-8352, 380-480 V wait at

least 20 minutes

Using VLT 8450-8600, 380-480 V wait at

least 15 minutes

Using VLT 8002-8006, 525-600 V wait at

least 4 minutes

Using VLT 8008-8027, 525-600 V wait at

least 15 minutes

Using VLT 8032-8300, 525-600 V wait at

least 30 minutes

NOTE

It is the user

’

s or certified electrician

’

s

responsibility to ensure correct grounding

and protection in accordance with applicable

national and local codes and standards.

■

Grounding

The following basic issues need to be considered

when installing an AFD.

•

Safety grounding:

Please note that the

AFD has a high leakage current and must

be grounded appropriately for safety reasons.

Apply local safety regulations.

•

High-frequency grounding:

Keep the ground

wire connections as short as possible.

Connect the different ground systems at the lowest

possible conductor impedance. The lowest possible

conductor impedance is obtained by keeping the

conductor as short as possible and by using the

greatest possible surface area. A flat conductor, for

example, has a lower HF impedance than a round

conductor for the same conductor cross-section C

VESS

.

If more than one device is installed in cabinets, the

cabinet rear plate, which must be made of metal,

should be used as a common ground reference

plate. The metal cabinets of the different devices are

mounted on the cabinet rear plate using the lowest

possible HF impedance. This avoids having different

HF voltages for the individual devices and avoids the

risk of radio interference currents running in connection

cables that may be used between the devices. The

radio interference will have been reduced.

In order to obtain a low HF impedance, use the

fastening bolts of the devices as HF connection to

the rear plate. It is necessary to remove insulating

paint or similar from the fastening points.

■

Cables

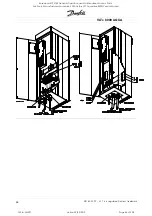

Control cables and the filtered line cable should

be installed separate from the motor cables so

as to avoid interference overcoupling. Normally,

a distance of 204mm (8 in) will be sufficient, but

it is recommended to keep the greatest possible

distance wherever possible, especially where cables

are installed in parallel over a substantial distance.

With respect to sensitive signal cables, such as

telephone cables and data cables, the greatest

possible distance is recommended with a minimum

of 1m (3 ft) per 5m (15 ft) of power cable (line

and motor cable). It must be pointed out that

the necessary distance depends on the sensitivity

of the installation and the signal cables, and that

therefore no precise values can be stated.

If cable jaws are used, sensitive signal cables

are not to be placed in the same cable jaws as

the motor cable or brake cable.

If signal cables are to cross power cables, this should

be done at an angle of 90 degrees.

Remember that all interference-filled in- or

outgoing cables to/from a cabinet should be

shielded/armored or filtered.

■

Shielded/armored cables

The shield must be a low HF-impedance shield.

This is ensured by using a braided shield of copper,

MG.80.A7.22 - VLT is a registered Danfoss trademark

52

Rosewood STP ST42 General (Operation and Maintenance Manual - Part 4:

Section 6.3 Manufacturers Manuals 6.3.33 Danfoss VLT Aquadrive 8000) Vendor Manual

QP Id: VM207

Active: 03/09/2013

Page 58 of 208