VLT

®

8000 AQUA

■

High voltage test

A high voltage test can be carried out by

short-circuiting terminals U, V, W, L

1

, L

2

and L

3

and energizing by max. 2.5 kV DC for one second

between this short-circuit and the chassis.

NOTE

The RFI switch must be closed (position ON)

when high voltage tests are carried out . The

line and motor connection must be interrupted

in the case of high voltage tests of the total installation

if the leakage currents are too high.

■

Heat emission from VLT 8000 AQUA

The tables in

General technical data

show the

power loss P

ϕ

(W) from VLT 8000 AQUA. The

maximum cooling air temperature t

IN, MAX

is 40° C

(104° F) at 100% load (of rated value).

■

Ventilation of integrated VLT 8000 AQUA

The quantity of air required for cooling AFD

can be calculated as follows:

1. Add up the values of P for all the AFDs to

be integrated in the same panel.

The highest cooling air temperature (t

IN

) present

must be lower than t

IN, MAX

40° C (104° F).

The day/night average must be 5°C (9° F) lower.

The outlet temperature of the cooling air must

not exceed: t

OUT, MAX

45° C (113° F).

2. Calculate the permissible difference between

the temperature of the cooling air (t

IN

) and

its outlet temperature (t

OUT

):

t= 45° C (113° F) -t

IN

.

3. Calculate the required

Insert

t in Kelvin

The outlet from the ventilation must be placed

above the highest-mounted AFD.

Allowance must be made for the pressure loss

across the filters and for the fact that the pressure

is going to drop as the filters are choked.

■

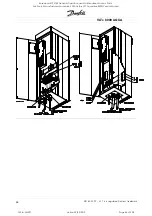

EMC-correct electrical installation

525-600 V units do not comply with European

EMC and Low Voltage Directives.

The following is a guideline to good engineering

practice, when installing drives. Following these

guidelines is advised, where compliance with EN

50081, EN 55011 or EN 61800-3

First environment

is required. If the installation is in EN 61800-3

Second environment,

then it is acceptable to

deviate from these guidelines. It is however not

recommended. See also

CE labelling, Emission

and

EMC test results

in this manual.

Good engineering practice to ensure

EMC-correct electrical installation:

•

Use only braided shielded/armored motor cables

and braided shielded/armored control cables. The

shield should provide a minimum coverage of 80%.

The shield material must be metal, not limited to

but typically copper, aluminum, steel or lead. There

are no special requirements for the line cable.

•

Installations using rigid metal conduits are not

required to use shielded cable, but the motor

cable must be installed in conduit separate from

the control and line cables. Full connection

of the conduit from the drive to the motor is

required. The EMC performance of flexible

conduits varies a lot and information from the

manufacturer must be obtained.

•

Connect the shield/armor/conduit to ground

at both ends for motor cables as well as for

control cables. See also

Grounding of braided

shielded/armored control cables

.

•

Avoid terminating the shield/armor with

twisted ends (pigtails). Such a termination

increases the high frequency impedance of the

shield, which reduces its effectiveness at high

frequencies. Use low impedance cable clamps

or EMC cable glands instead.

•

It is important to have good electrical contact

between the mounting plate on which the AFD is

installed and the metal chassis of the AFD unit.

Exception:

-

IP54/NEMA 12 units designed for wall mounting

-

VLT 8152-8600 (380-480 V) IP20/NEMA 1

-

VLT 8042-8062 (200-240 V) IP20/NEMA 1

MG.80.A7.22 - VLT is a registered Danfoss trademark

56

Rosewood STP ST42 General (Operation and Maintenance Manual - Part 4:

Section 6.3 Manufacturers Manuals 6.3.33 Danfoss VLT Aquadrive 8000) Vendor Manual

QP Id: VM207

Active: 03/09/2013

Page 62 of 208