39

E

N

G

L

IS

H

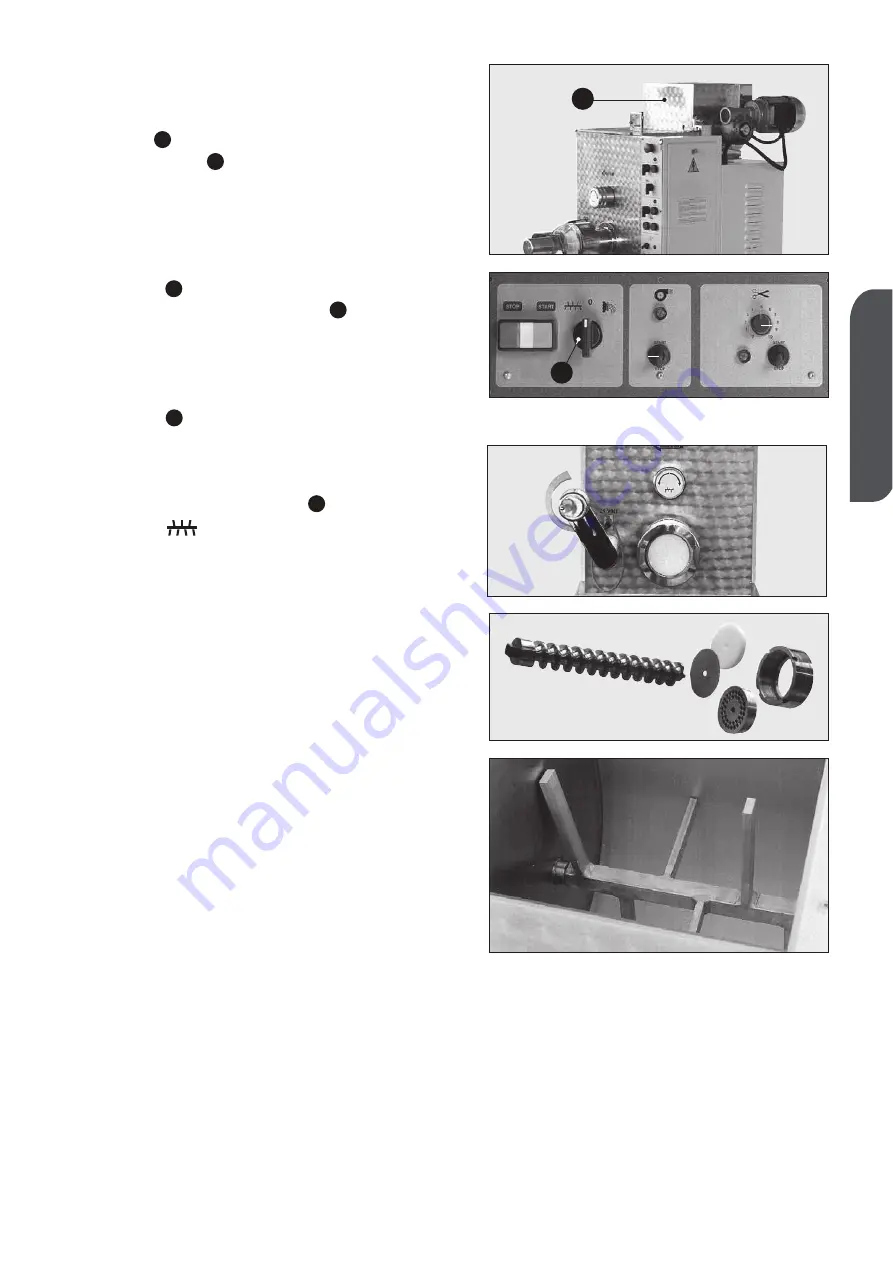

3.5 VARIANT FOR MOD. TRD 110

The TRD 110 model uses the second tank

(

Fig. 13

) to enable dough to be kneaded

(press button

-

Fig. 12

) simultaneously

with the worm screw extrusion stage. This

allows output to be increased considerably.

Make the dough as shown for the main tank

then tip it into the main tank while rotating it

manually. To carry out this operation release

the knob

(

Fig. 31

) and rotate the tank by

means of the lever (

Fig. 31

), to obtain

continuous cycle production.

After the operation:

• stop the machine by switching the selector

(

Fig. 15

) as well as the others to the “0”

position;

• rotate the cutting group to the stop position

(

Fig. 16

);

• turn the selector (

Fig. 15

) to the knead

position

for 10-15 seconds in order to

eliminate the pressure on the die caused

by the product ;

• return the switch to “0”;

• disassemble and wash the movable parts

(

Fig. 17 - 18

) and clean the machine (see

Unit 6 CLEANING page 45);

• close the water tap, for machines fitted with

a cooled extrusion sleeve.

D

C

B

A

A

B

Fig. 13

B

Fig. 15

A

Fig. 16

Fig. 17

Fig. 18