43

E

N

G

L

IS

H

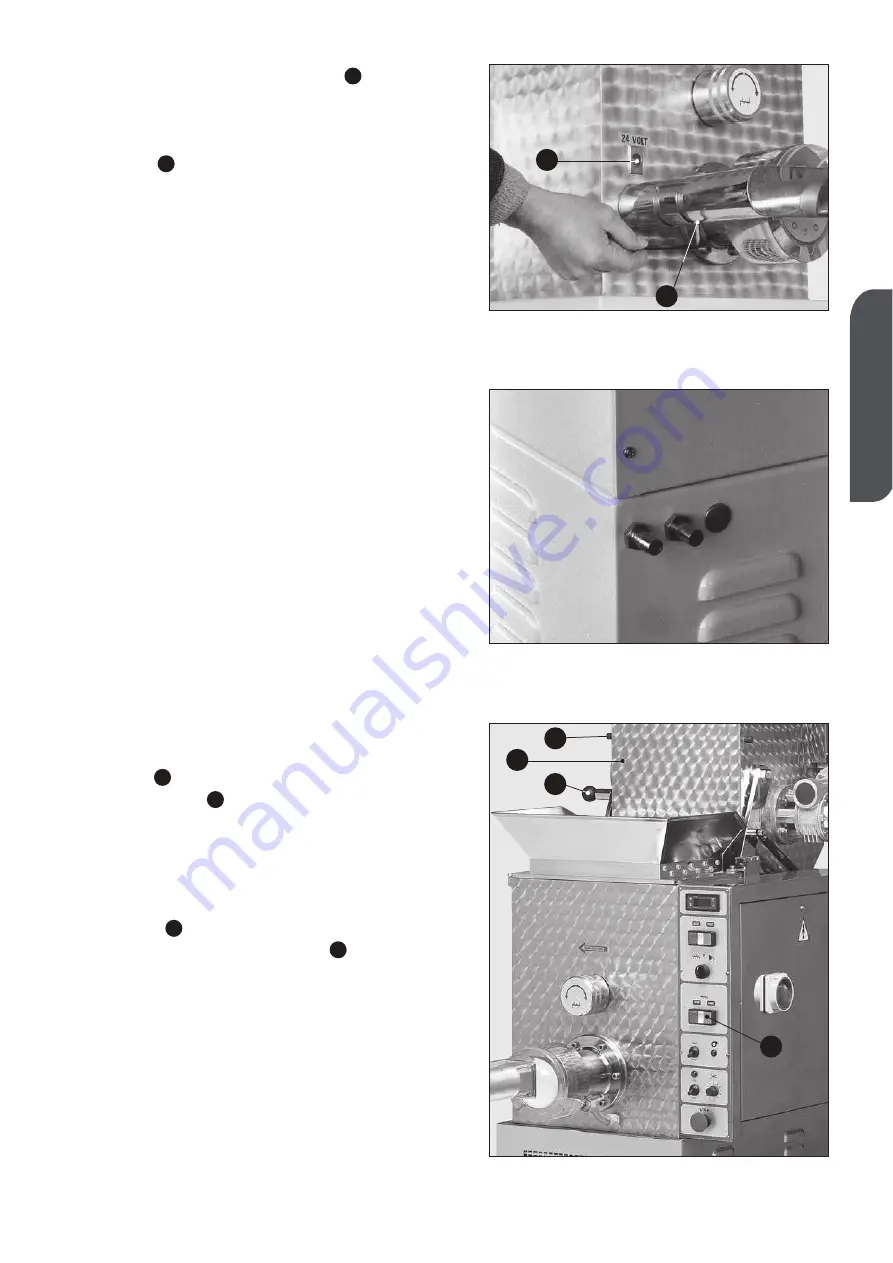

the socket-head screw (

Fig. 29

) from the

bearing. Then tighten the screws right down

again (

Fig. 29

).

Plug the unit into the power supply socket

(

Fig. 29

) of the machine; let the safety

coupling click in.

5.2 CONNECTION TO THE WATER SYSTEM

For machines supplied with

an extrusion

sleeve cooling system,

connect the machi-

ne to the water system, install the sending

tube, (when it is non-existant: use a tap, pos-

sibly with screw-control) to the outer part of

the machine, in order to regulate the water

flow. The exit-flow tube must allow free water

discharge. We recommend that the water

pressure inside the machine, does not

exceed the 1.0 - 1.5 bar.

To connect the external parts, use a flexible

tube with an inside diameter of 13 mm,

safely fixed by a metal band with a screw

that can be closed with a screw-driver or key

(

Fig. 30

).

5.3 VARIANT FOR MOD. TRD 110 S

The TRD 110 S model uses the second tank

(

Fig. 31

) to enable dough to be kneaded

(press button

-

Fig. 31

) simultaneously

with the worm screw extrusion stage. This

allows output to be increased considerably.

Make the dough as shown for the main tank

then tip it into the main tank while rotating it

manually. To carry out this operation release

the knob

(

Fig. 31

) and rotate the tank by

means of the lever (

Fig. 31

), to obtain

continuous cycle production.

D

C

B

A

B

A

Fig. 30

Fig. 31

Fig. 29

A

B

A

C

D

B