44

5.4 CONTROL OF THE INSTALLATION

N.B.: Every operation is voluntarily com-

manded by means of the start but-

ton with the tank safety lid closed

by means of the double safety devi-

ce.

Turn the selector to the knead position

(

Fig. 32

) and check:

• Make sure that the mixer is rotating coun-

ter-clockwise, facing the front of the machi-

ne, when the switch (

Fig. 32

) is placed

on the “mix” position

, (the Archime -

dean screw also turns counter-clockwise).

In the “0” position all of the machine’s ele-

ments should be still; in the drawplate posi-

tion

, the mixer turns clockwise, the

Archimedean screw should turn the same

way (check from the lid slits).

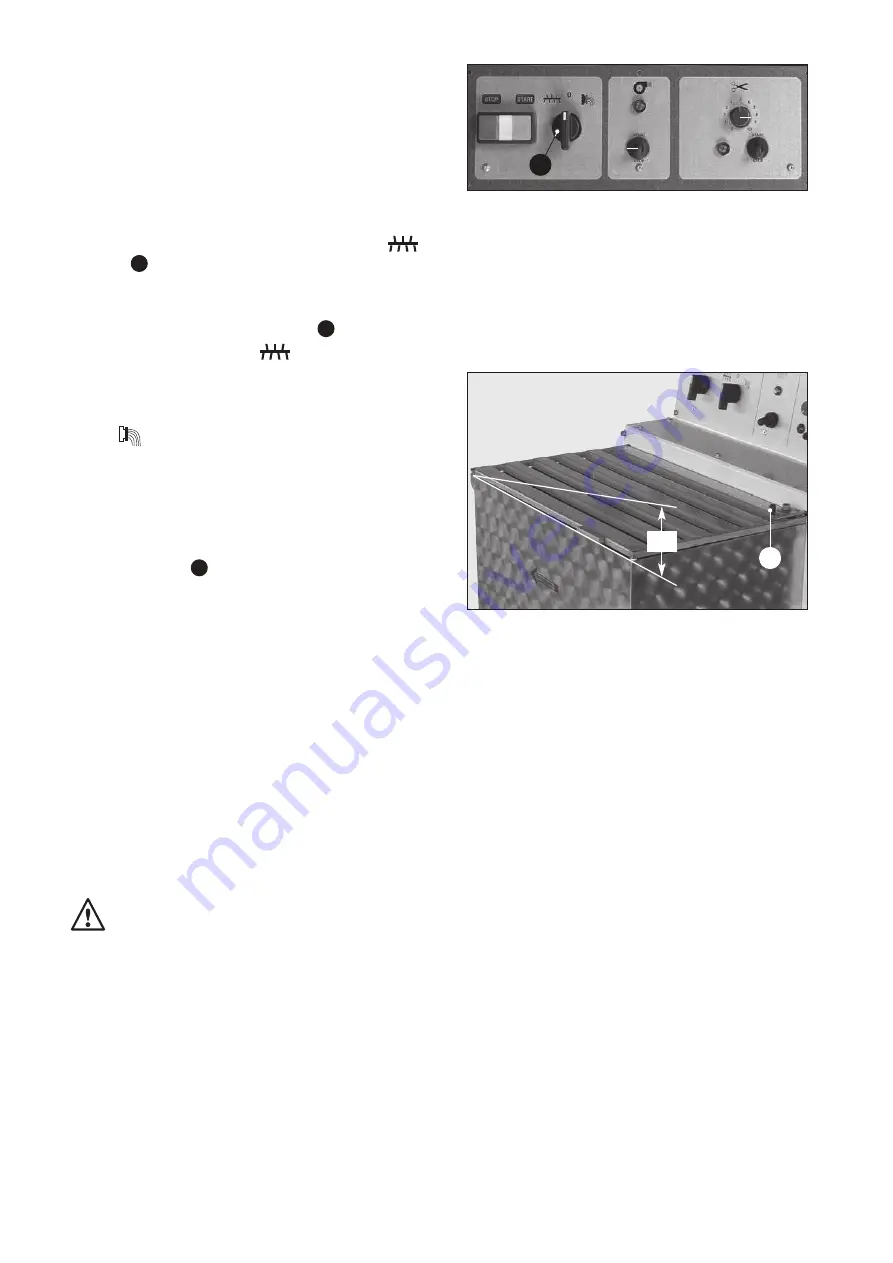

• Check the efficiency of the double safety

device on the lid. The device sets off two

micro-switches; one is controlled by the lid

hook (

Fig. 33

), inside the stop slot; and

the other from the lid itself.

To check this, make sure that microswitch

in the slot begins to be enabled when the

hook has not yet gone out of the slot itself.

The lid microswitch must be heard to click

when the lid is lifted approx. 10 - 15 mm.

(

Fig. 33

).

• Operation of the buttons and pilot lamps

according to the signs given (

Fig. 32

).

• The knife in its working position should be

turning clockwise.

• The correct connection of the water cooling

system, should include checking for even-

tual water leaks.

If the machine or some of its parts

breakdown, call your local authorised

dealer or concessionaire for repairs.

A

A

A

Fig. 32

Fig. 33

10-15

mm

A

A