2

© 2021,

ROSS

CONTROLS

®

.

All Rights Reserved.

3/2 RSe Series Safe Exhaust Double Valves Integration Guide

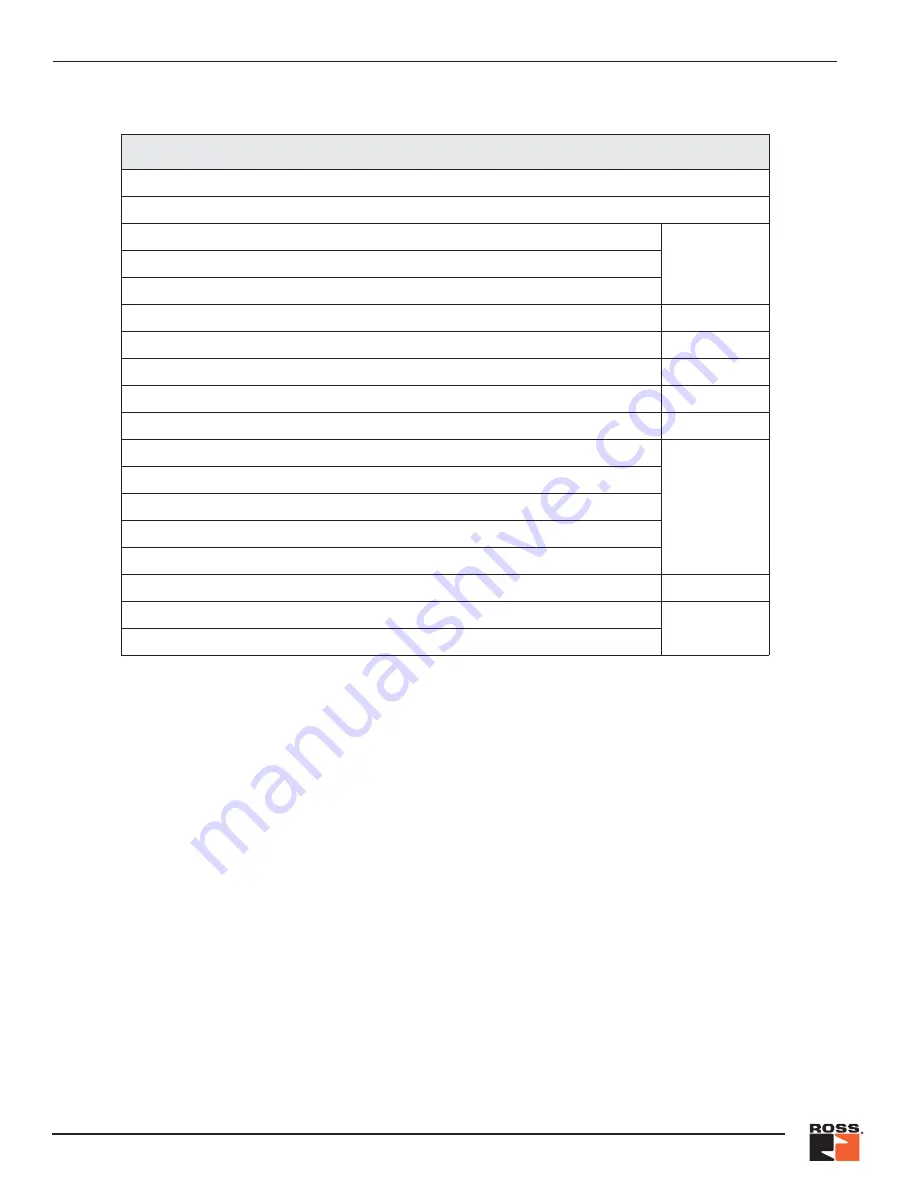

Table of Contents

Integration Guide – 3/2 RSe Series Safe Exhaust Double Valves

Page

General Information

Introduction

3

Pulse Testing

Exhaust Times and Faulted Flow Rates

RSe Wiring (Pinouts)

4

Pilot Supply Conversion

4 - 5

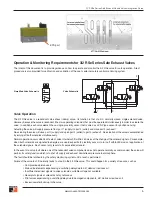

Operation & Monitoring Requirements for 3/2 RSe Series Safe Exhaust Valves

5

Valve Operation

5

Feedback Monitoring (General)

6

Actuation Fault Monitoring

7

De-Actuation Fault Monitoring

Loss of Supply Pressure While Actuated

No Supply Pressure Applied Before Actuation

Valve Fault & Safety System Reset

Validation Test Procedure for Valve Operation and External Monitoring Logic

8 - 10

Cautions, Warnings and Standard Warranty

Cover

Global Locations

Disclaimer:

Sample Logic and any and all related diagrams contained in ROSS Controls’ Integration guide were developed and

validated using dual channel electro-mechanical input signals in a laboratory environment and are provided to you

for illustrative purposes only. Because of the many variables and unique requirements associated with any particular

application, all persons responsible for installing and integrating ROSS products must satisfy themselves that the ROSS

product is the correct product for the application and operates as intended. Because of the variability described above,

ROSS Controls cannot assume responsibility or liability for actual use of its products based upon samples, examples

and diagrams contained in its websites and documents.