4

© 2021,

ROSS

CONTROLS

®

.

All Rights Reserved.

3/2 RSe Series Safe Exhaust Double Valves Integration Guide

RSe Wiring (Pinouts)

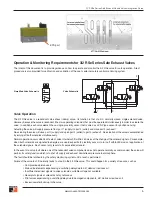

The RSe wiring connections are made via EN175301-803, Form C receptacles for

the solenoids and male M8 receptacles on the sensors. Pinouts are shown below.

Solenoids & Position Sensors

Pinouts

NOTE:

The sensors must be wired with 24 volt (+) and 0 volt (-) connections in parallel with each other.

GRN/YEL

GROUND

BROWN

BLUE

GRN/YEL

Solenoid Cables with

EN Connector

GRN/YEL

GROUND

3

2

1

4

BLUE

PIN 2

BROWN

PIN 1

Sensor Wiring M8 Connector

1

3

4

1

3

4

L+

L-

1 Brown

3 Blue

4 Black

Wire Colors

Pilot Supply Conversion

The RSe Series valve comes from the factory configured for internal pilot supply, which sources pilot supply air pressure internally

from port 1 in the valve sub-base. However, the valve can be converted in the field to operate with external pilot supply through

the EPS port in the valve sub-base. When this conversion to external pilot supply is made, the valve solenoid pilots will get their

supply air from a source that is independent of the supply line connected to Port 1.

External pilot supply is typically used in applications where the normal supply pressure may be lower than the minimum operating

pressure of the valve (45 psig (3 bar)).

In order to convert the RSe valve to external pilot supply:

A. Shut off and exhaust all pressure from the system and disconnect all electrical power from the valve.

B. Remove the valve from the sub-base (4 screws). See photo below.

C. Remove the set screw from the external pilot supply port in the top of the base. See figures below.

D. Install the set screw in the internal pilot supply port in the top of the sub-base (max. torque 49 in-lbs (5.5 Nm). See figures below.

E. Install an external pilot supply line into the EPS port in the side of the sub-base. The source for this external pilot supply should

supply a constant supply of air with pressure greater than or equal to the supply pressure in Port 1; 45 psig (3 bar) minimum.

F. Re-install the valve on the sub-base (4 screws - max. torque 49 in-lbs (5.5 Nm)). See photo below.

Solenoids

Sensors

EPS port

EPS port

Mounting Screws

Mounting Screws