6

© 2021,

ROSS

CONTROLS

®

.

All Rights Reserved.

3/2 RSe Series Safe Exhaust Double Valves Integration Guide

Feedback Monitoring (General)

The 3/2 RSe valve is equipped with feedback proximity sensors that must be monitored by the user’s external safety control &

monitoring system to detect any fault condition within the valve. Sensor feedback should always be opposite the solenoid actuating

signals. In other words, when the solenoids are energized, the sensor outputs should be off and when the solenoids are de-

energized, the sensor outputs should be on.

WARNING:

It is possible to operate at a cycle rate that could result in non-monitored operation. To prevent exceeding this rate,

ensure that the valve is de-actuated (both sensor outputs should be on) before attempting to energize the solenoids. Likewise,

ensure that the valve is actuated (both sensor outputs should be off) before attempting to de-energize the solenoids.

NOTE:

In the event of a stop signal from any safety system input, the safety system should immediately shut off the safety controller

outputs to the valve solenoids (as required by the application) regardless of the condition of the feedback sensors.

Refer to EN ISO13849-1 for Cat 3 vs Cat 4 monitoring.

Automatic RESET is not recommended by ROSS.

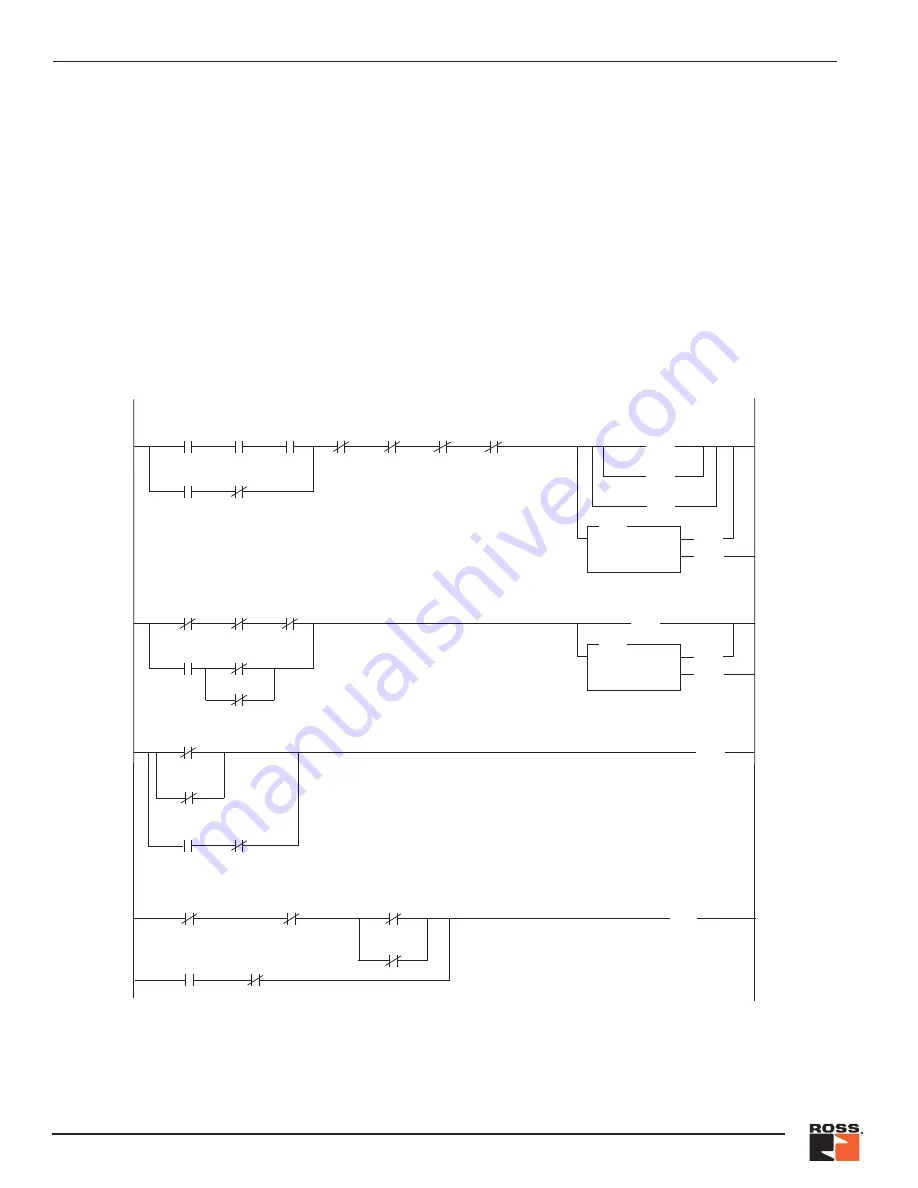

Valve Operation and General Feedback Monitoring Ladder Logic Example

Actuate

Signal

Sensor

A

Sensor

B

Safety

Stop

Signal

General

Feedback

Fault

Solenoids Energized

Solenoid A

Solenoids

Energized

Solenoids

De-energized

Sensor

B

Sensor

A

Actuate

Signal

< >

< >

< >

Solenoid B

< >

Solenoids De-energized

De-actuation

Fault

*

Actuation

Fault

*

Solenoids

De-energized

Sensor

A

EN

< >

< >

DN

TON

Timer On Delay

Actuation Timer

Timer Value = 250 msec

EN

< >

< >

DN

TON

Timer On Delay

De-actuation Timer

Timer Value = 250 msec

Sensor B

E-Stop Button

Safety Stop Signal

Reset

Door Interlook

Switch

**

< >

Safety Stop

Signal

*

Explained in the next sections.

**

Could be an Input from any Safety Device,

such as a light curtain.

Sensor

A

Solenoids

Energized

Solenoids

De-energized

General Feedback Fault

Reset

< >

General Feedback

Fault

Sensor

B