8

© 2021,

ROSS

CONTROLS

®

.

All Rights Reserved.

3/2 RSe Series Safe Exhaust Double Valves Integration Guide

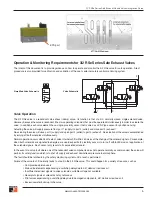

NOTE 1:

This validation test procedure should only be performed with a 3/2 RSe valve that is known to be functioning properly. If basic valve function is in

question please refer to Section 8 of the Product Operating Instructions for the Valve Test Procedure.

NOTE 2:

These procedures require fault simulation. It will be necessary to induce faults electrically by disabling a different solenoid or sensor at different times.

This will be most easily done by disconnecting solenoid or sensor cables at the valve.

NOTE 3:

Port 2 should be connected to a gauge or pressure sensor teed into the line.

NOTE 4:

Supply pressure will need to be supplied to inlet port 1.

NOTE 5:

This procedure pertains to internal pilot configuration only.

NOTE 6:

“-“ indicates no change from previous step.

NOTE 7:

Actuate Signal is the signal to switch on the solenoids either from a physical input switch or a software signal.

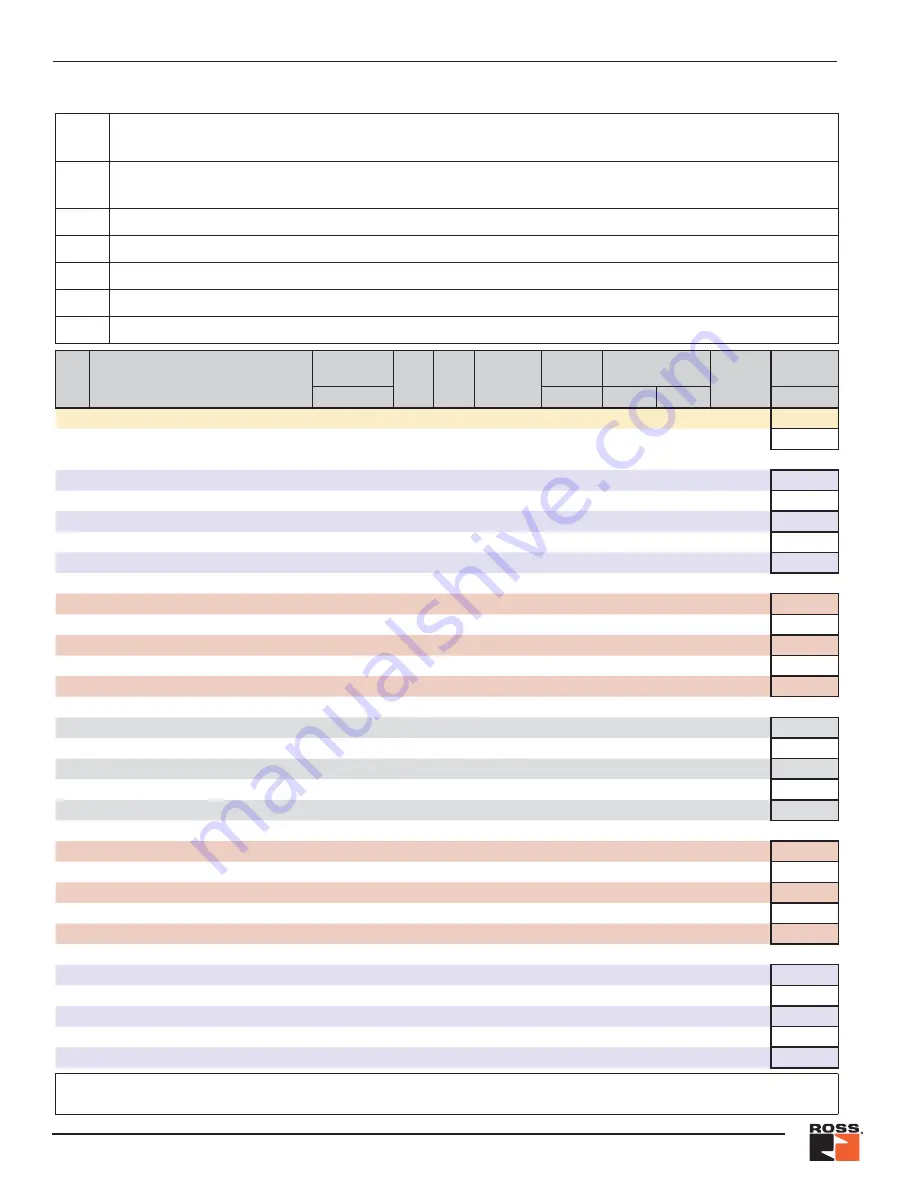

RSe (3/2) Validation Test Procedure for Valve Operation and External Monitoring Logic

Step

Action

Actuate Signal

Sol A

Sol B

Port

Conditions

Outlet

Pressure

Sensor Conditions

Fault ?

Pass/Fail

Sol A & Sol B

Port 2

Sensor A Sensor B

(P/F)

1

Energize solenoids A & B

ON

ON

ON

1 to 2 | 3

Pressure

OFF

OFF

No

2

De-energize solenoids A & B

OFF

OFF

OFF

1 | 2 to 3

None

ON

ON

-

3

Disconnect solenoid cable from solenoid B

OFF

OFF

OFF

1 | 2 to 3

None

ON

ON

No

4

Attempt to energize solenoids A & B

ON

-

-

-

-

-

-

Yes

*

5

Reconnect solenoid B

-

-

-

-

-

-

-

-

6

De-energize solenoids A & B

OFF

-

-

-

-

-

-

-

7

Reset the safety control system

-

-

-

-

-

-

-

No

8

Disconnect solenoid cable from solenoid A

OFF

OFF

OFF

1 | 2 to 3

None

ON

ON

No

9

Attempt to energize solenoids A & B

ON

-

-

-

-

-

-

Yes

*

10

Reconnect solenoid A

-

-

-

-

-

-

-

-

11

De-energize solenoids A & B

OFF

-

-

-

-

-

-

-

12

Reset the safety control system

-

-

-

-

-

-

-

No

13

Energize solenoids A & B

ON

ON

ON

1 to 2 | 3

Pressure

OFF

OFF

No

14

Disconnect solenoid cable from solenoid A

-

OFF

OFF

1 | 2 to 3

None

ON

ON

Yes

**

15

Reconnect solenoid cable to solenoid A

-

-

-

-

-

-

-

-

16

De-energize solenoids A & B

OFF

-

-

-

-

-

-

-

17

Reset the safety control system

-

-

-

-

-

-

-

No

18

Energize solenoids A & B

ON

ON

ON

1 to 2 | 3

Pressure

OFF

OFF

No

19

Disconnect solenoid cable from solenoid B

-

OFF

OFF

1 | 2 to 3

None

ON

ON

Yes

**

20

Reconnect solenoid cable to solenoid B

-

-

-

-

-

-

-

-

21

De-energize solenoids A & B

OFF

-

-

-

-

-

-

-

22

Reset the safety control system

-

-

-

-

-

-

-

No

23

Disconnect sensor cable from sensor A

OFF

OFF

OFF

1 | 2 to 3

None

OFF

ON

Yes

**

24

Attempt to energize solenoids A & B

ON

-

-

-

-

-

-

-

25

De-energize solenoids A & B

OFF

-

-

-

-

-

-

-

26

Reconnect sensor cable to sensor A

-

-

-

-

-

ON

-

-

27

Reset the safety control system

-

-

-

-

-

-

-

No

*

Fault should be detected within 250 msec.

**

Fault should occur immediately.