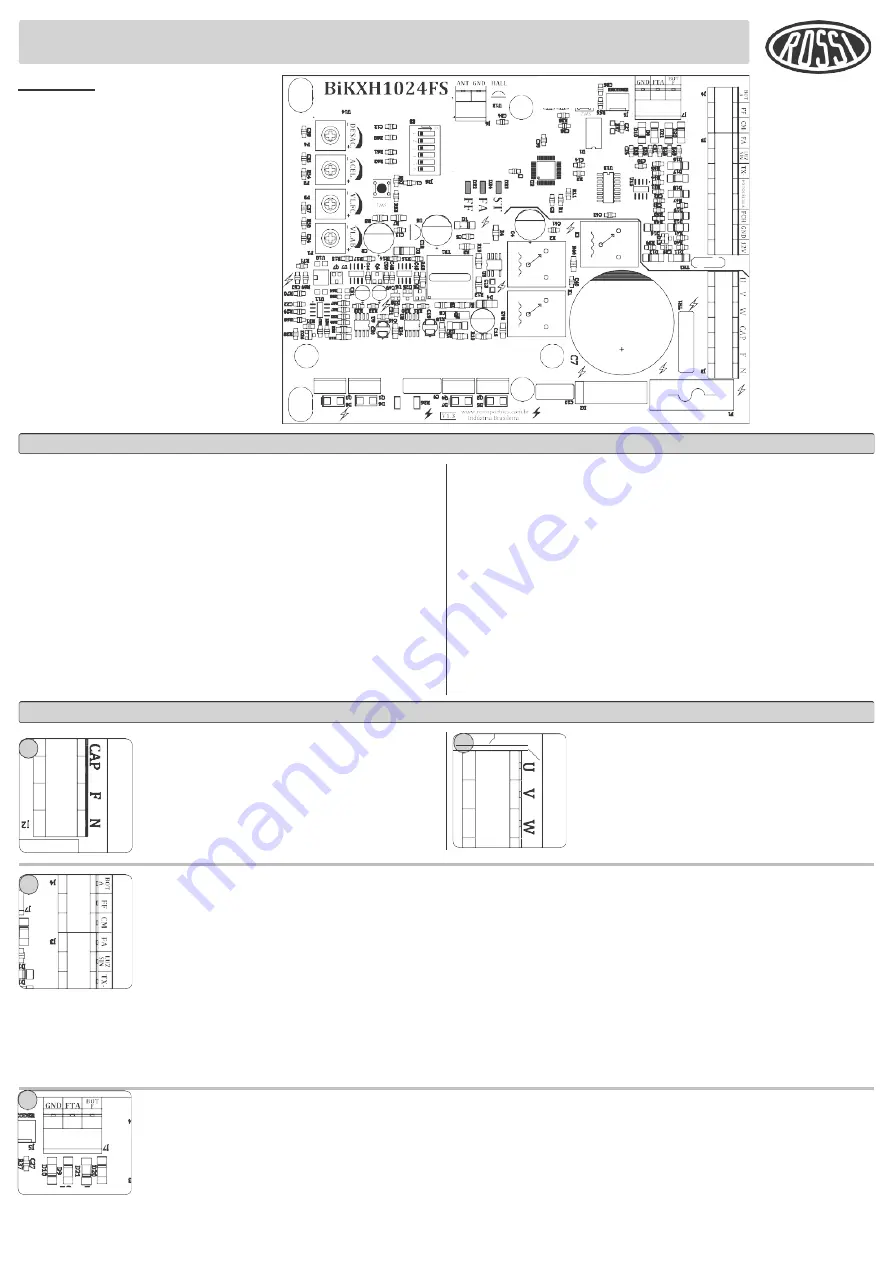

Bi KXH1024FS

FAIL SAFE

FUNCTION

Installation Manual

Features

-

Automatic source 90V - 240V ~ ac

-

Motor with maximum power 520W

-

End of stroke sensor HALL and Reed Switch

-

Internal memory for 1024 removable buttons

-

HCS reception system, anti-cloning

-

Frequency of reception 433 Mhz

-

Acceleration adjustment

-

Deceleration adjustment

-

Aperture speed adjustment

-

Closing speed adjustment

-

Residential and building function

-

Automatic electronic clutch

-

Clears access key individual code

-

Output for traffic light / garage light

-

Entry for closing photocell

-

Input for opening photocell

-

Lock Output

-

Adjustable automatic closing

-

Opening and closing switch

-

Independent closing switch

-

Auto reverse function

Smart Products

N - Neutral / Phase 2

F - Phase (Electrical Network Input 90 ~ 240VAC)

CAP - Permanent Capacitor

U/V/W - Motor wires (U = Common, yellow wire)

--------------------------------------------------------------------------------------------------------

12V - Output 12VDC -300mA (for ROSSI accessories)

GND - Common for 12V Output and Accessories

FCH - Output for Locking Plate

PHOTOCELL - Input Photocell closing - RX TX (-) -

Negative Photocell FS

SIN LIGHT - Traffic Light / Garage

Light FA - End of opening stroke

CM - Common for Ends of Strokes and FF

Switch - Closing End of Stroke

BOT_A - Opening Switch

--------------------------------------------------------------------------------------------------------

GND - Common for Opening Photocell and FTA Closing Switch - Opening

Photocell

BOT_F - Closing Switch

GND - Coaxial Cable Mesh for External Antenna

ANT - Coaxial Cable Core for External Antenna / Internal Antenna Wire

ADJUSTMENTS - Functional Settings Button / Path Recognition LEARN - Learn /

Delete Remote Control Button

ST - Led Event Indicator

FA - Green Led Open gate indicator

FF - Red Led Closed Gate Indicator

--------------------------------------------------------------------------------------------------------------

DIP-1 BUILDING- Building= ON / Residential = OFF

DIP-2 PAUSE - Auto Lock Enabled = ON / Disabled = OFF DIP-3 LOCK - Lock

/ Lock Enabled = ON / Disabled = OFF DIP-4 LV / PS - Heavy Gate = ON /

Light Gate = OFF

DIP-5 DZ / BV - Vertical Tilting= ON / Slider = OFF

DIP-6 FS - Fail Safe Function Enabled = ON / Disabled = OFF

--------------------------------------------------------------------------------------------------------------

ACEL - Acceleration setting DECEL-

Deceleration adjustment

VL.AB - Gate opening speed adjustment. VL.FC - Gate

closing speed adjustment.

N / F - Input 90 ~ 240VAC

Voltage input already intercepted by a 10A bipolar circuit

breaker and grounding the equipment.

CAP

-Permanent Capacitor

Capacitor according to the motor power, the wires have no

polarity.

Ends of stroke:

U - V - W - Motor Wires

Note: Motor with maximum power up to 520W

The motor has 3 wires. The common (check label on the

motor) usually the yellow one must be connected to the U

output.

The outputs V and W determine the motor rotation direction

(right - left).

To do this test, leave the gate in the middle of the path (far

from the end of the course) and press, the LED FF or FA will

flash indicating the direction of rotation of closing or

opening.

The control unit automatically understands the two end-of-course systems, by contact (reed) and/or hall without programming.

NOTE: You should always use your own magnet for

hall sensor Ends of Stroke Reed CM-FA-FF

Randomly pick one end of each row of each end of stroke sensor and one forming a common one.

The other two ends will be FF (closed) and FA (open). Connect the wires to the respective terminals FF, FA and CM (common).

Observe the ends of stroke position on the drive so that the closed gate illuminates the red LED FF, and when the green LED FA is opened, it will light

up.

Sensor Hall End of Stroke

The hall sensor identifies the polarity of the magnets, north and south. Before fixing the magnets, identify the FA and FF by moving the magnet on

the rack until it passes in front of the hall sensor that will light the green led FA or red FF. (If both magnets light up the same led, reverse the

position of the magnet that does not match the chosen Open or Closed side.)

BOT_A/GND,

The Opening Button consists of installing a buzzer (bell type) button on the terminal (BOT_A) of the control panel, interconnecting a receiver or an external

control system.

SIN -GND

- Traffic light consists of interconnecting a traffic light with the central gate using the terminals SIN and GND.

LIGHT -GND

- Garage light. to interconnect garage LIGHT accessory board, using the bornes LIGHT and GND.

BOT_A/GND

, The Opening Button consists of installing a buzzer (bell type) button on the terminal (BOT_A) of the control panel, interconnecting a

receiver or an external control system. The single door closing function is activated after pressing and

releasing

the button.

Note

: The Switch is used for manual activation in booths, activation by the intercom or possible need for remote activation by external button.

With SETUP to 1X (default function), BUTTON functions as "open-close" and BOT F only stops and closes.

With SETUP to 2X the BUTTON only opens and BOT F only closes after releasing the button of the switch.

FTA -

Photocell opening

Photocell must be turned on in Normally NA (Normally Open) mode it only acts on the opening control not reversing the gate.

Code 13247 - Rev 05

Page01

Layout and

Components

Installatio

n

1-

2-

3-

4-

5-

6-

2

1

3

4

ADJUST

MENTS

1-BUILDING

2-PAUSE

3-LOCK

4-LV / PS

5-DZ/BV

6-FS

LE

A

RN